4.

Set parking brake switch (4) to ON position (A) to apply the

parking brake.

NOTICE

Applying the parking brake automatically sets the

transmission to NEUTRAL.

5.

Operate boom control lever (5) to lower the bucket to the

ground.

6.

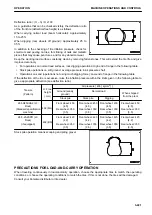

Check that boom control lever (5) and bucket control lever (6) are in HOLD position.

Lock the work equipment (the pilot lamp lights up) with

work equipment lock switch (7).

To secure a sufficient space to get off the machine, move the operator's seat backward if it is positioned forward.

METHOD FOR CHECKING AFTER FINISHING WORK

CHECKS BEFORE STOPPING ENGINE

On the machine monitor, check the engine coolant temperature, hydraulic oil temperature, torque converter oil

temperature, remaining fuel level, and remaining DEF level.

If the engine has overheated, do not stop the engine suddenly. Run it at a medium speed to cool it gradually

before stopping.

CHECKS AFTER STOPPING ENGINE

1.

Perform walk-around check for oil or coolant leakage and for abnormality in work equipment, exterior parts,

and undercarriage.

If oil or coolant leakage or any abnormality is detected, repair it.

2.

Check DEF tank, pump, injector, hose, and joint for leakage.

If any abnormality is found, ask your Komatsu distributor for repair.

3.

Fill the fuel tank.

4.

Check the engine compartment for paper and debris. Clean out any paper and debris to avoid a fire hazard.

5.

Remove any mud affixed to the undercarriage.

OPERATION

MACHINE OPERATIONS AND CONTROLS

3-217

Summary of Contents for WA480-8

Page 2: ......

Page 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Page 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Page 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

Page 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Page 324: ......

Page 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Page 402: ......

Page 403: ...SPECIFICATIONS 5 1...

Page 406: ......

Page 422: ......

Page 423: ...REPLACEMENT PARTS 7 1...

Page 439: ......