METHOD FOR CHECKING AND INFLATING TIRE

k

k

WARNING

• When pumping up the tires, check that no other person is standing near the tire, and install an air

chuck with a clip that can be secured to the air valve.

• To prevent the tire inflation pressure from becoming too high, measure the pressure from time to

time with an air gauge while pumping up the tire.

• When it is inflated, the rim parts may fly out, if they are not fitted properly.

Put a fence around the tire for protection. The worker must not stand in front of the rim but must

stand on the tread side during work.

• Abnormal drop of inflation pressure and abnormal fitting of the rim indicate a trouble in the tire or

rim. In this case, be sure to ask a tire repair shop for repair.

• Be sure to observe the specified inflation pressure.

• Do not adjust the tire inflation pressure immediately after traveling at high speed or operating under

heavy load.

Check the tire inflation pressure before starting work while the tires are cold.

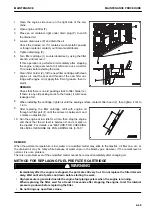

When inflating a tire, use an air chuck which can be fixed to the air valve of the tire as shown in the figure.

Do not work in front of the rim but work on the tread side of the

tire.

1.

Measure the inflation pressure with a tire inflation pressure gauge.

2.

Adjust the inflation pressure properly.

The proper inflation pressure is shown below.

Tire size

Standard inflation pressure

Standard

26.5R25XHA2

Front wheel: 450 kPa {4.5 kg/cm

2

}

Rear wheel: 350 kPa {3.5 kg/cm

2

}

Optional

26.5-25-20PR

Front wheel: 420 kPa {4.2 kg/cm

2

}

Rear wheel: 350 kPa {3.5 kg/cm

2

}

NOTICE

Appropriate inflation pressure varies depending on the given type of work. For details, see “HAN-

DLE TIRE (3-220)”.

METHOD FOR CLEANING AND REPLACING FUEL BREATHER FILTER

k

k

CAUTION

If you inspect or clean while engine is running, dirt enters the fuel tank and damages the engine.

Be sure to stop the engine before performing these works.

MAINTENANCE

MAINTENANCE PROCEDURE

4-37

Summary of Contents for WA480-8

Page 2: ......

Page 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Page 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Page 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

Page 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Page 324: ......

Page 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Page 402: ......

Page 403: ...SPECIFICATIONS 5 1...

Page 406: ......

Page 422: ......

Page 423: ...REPLACEMENT PARTS 7 1...

Page 439: ......