REMARK

If the purified water is added to above the bottom of the sleeve, use a syringe to remove electrolyte. Neu-

tralize the removed fluid with baking soda (sodium bicarbonate), then flush it away with a large amount of

water. If necessary, consult your Komatsu distributor or a battery manufacturer.

METHOD FOR CHECKING ELECTROLYTE LEVEL WHEN IT IS POSSIBLE TO

USE INDICATOR TO CHECK ELECTROLYTE LEVEL

If it is possible to use an indicator to check the electrolyte level, follow the instructions given.

METHOD FOR TESTING PARKING BRAKE

1.

Stop the machine by using the brake pedal on a dry slope road (downhill).

2.

Set the parking brake switch from OFF position (B) to ON

position (A).

3.

Check that the machine is stopped and held at the current

position.

If any problem is found, ask your Komatsu distributor for

adjustment.

METHOD FOR CHECKING AND ADJUSTING AIR CONDITIONER COMPRESSOR

BELT TENSION

k

k

WARNING

When checking and adjusting the air conditioner compressor belt tension, stop the engine, and display

the warning tag on the work equipment control lever.

METHOD FOR CHECKING AIR CONDITIONER COMPRESSOR BELT

1.

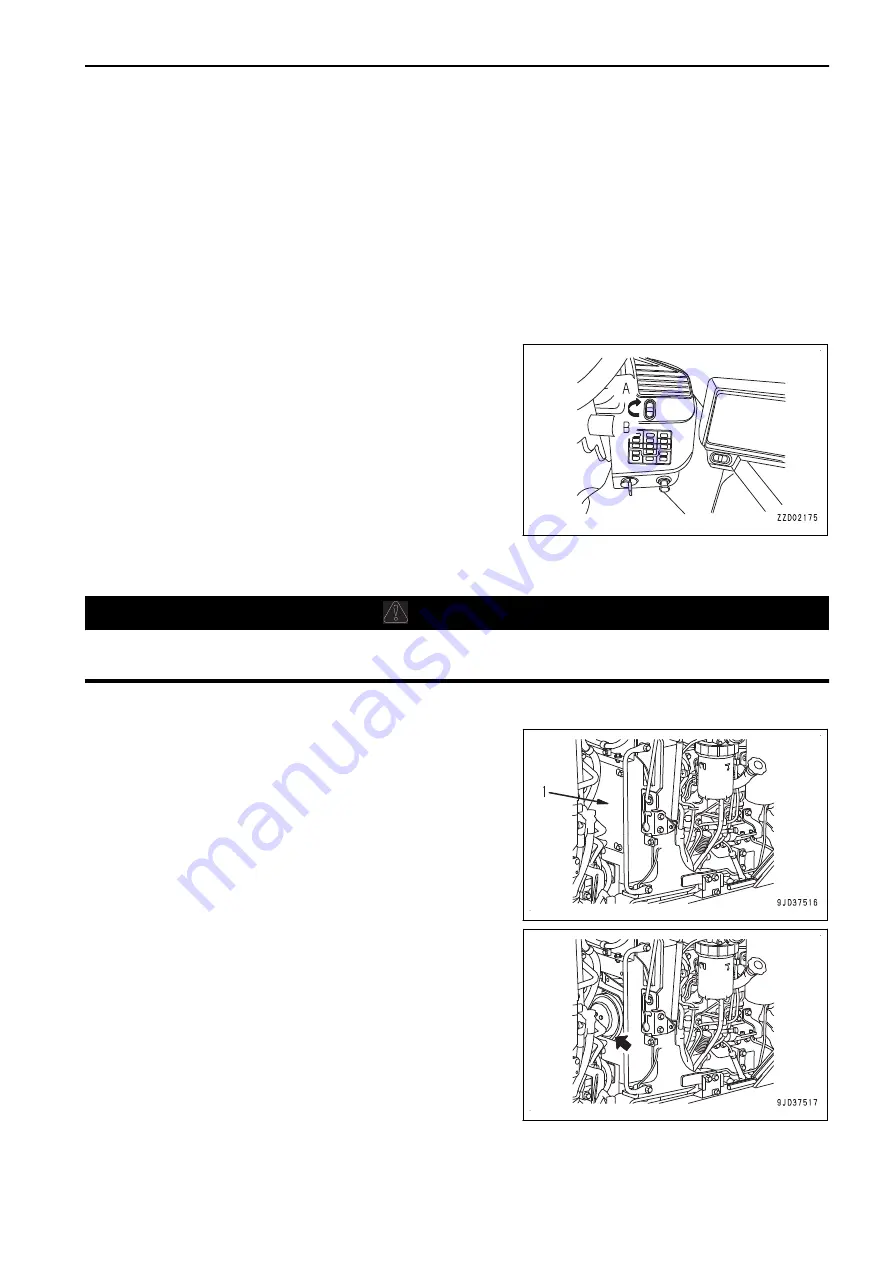

Open the engine side cover on the right side of the ma-

chine.

2.

Loosen the bolts (4 pieces) and remove cover (1).

3.

Press the middle point between the compressor pulley and

crankshaft pulley with your thumb (approximately 98 N

{10 kg} ).

If the belt defects approximately 25 to 26 mm, its tension is

normal.

When you use a belt tension gauge, the tension is normal

if it is in the range of 294 to 441 N {30 to 45 kg} .

4.

After checking, install cover (1).

MAINTENANCE

MAINTENANCE PROCEDURE

4-45

Summary of Contents for WA480-8

Page 2: ......

Page 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Page 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Page 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

Page 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Page 324: ......

Page 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Page 402: ......

Page 403: ...SPECIFICATIONS 5 1...

Page 406: ......

Page 422: ......

Page 423: ...REPLACEMENT PARTS 7 1...

Page 439: ......