KLARO GmbH

24

Original Operating Manual for KLARO Small Wastewater Treatment Plant V.15.07

6.1.1. Mode of Operation

The water level is measured by the pressure in the

charging lifter during the charging phase. If the water

level in the sludge storage/buffer (chamber 1)

exceeds a preset fill level ("level measurement

setting "), the system starts a treatment cycle. If the

level is not reached, the system enters into cycle

pause for 6 hours. During the pause, the SBR

reactor is aerated only occasionally in order to keep

the bacteria alive. After 4 consecutive measurements

during which the preset water level in the first

chamber is not reached, the plant will pump water

back from the reactor into the first chamber via the

excess sludge lifter (recirculation). This will create an

artificial supply and the water level rises, which can

cause a cycle start after the following

measurements. The duration of the

recirculation, and thus the delivered volume of

water, can be adjusted in the service menu. As a result, the reactor is given a new supply after a certain

time even in the event of little or no wastewater supply. The regular treatment line can therefore be

maintained over a longer period even in the absence or underload of wastewater.

The number of treatment cycles performed can be queried via the menu item Operating Hours. The

treatment cycles actually carried out are compared with the cycles running in automatic mode (4 per day)

and displayed as a percentage (25% to 100% use of capacity).

6.1.2. Commissioning

Fall Hazard

When working near the open cover of the septic tank, there is a hazard of tripping

and falling!

The open tank must be secured by appropriate measures.

The first chamber (sludge storage/buffer), in which the charging lifter is located, must be filled with water

up to the level at which a treatment cycle is to be triggered. For this purpose, a marking with the

recommended fill level is attached to the charging lifter

airlift

.blue.

1st step: Calibrating the pressure sensor,

The calibration of the sensor is essential for the commissioning of the underload detection. Please go

through the following points carefully in order:

Service Code

Input

Go to the menu item "SERVICE CODE INPUT," press the

key and enter

the following code when prompted: 9 9 9 9

Calibrate?

No

Use the arrow keys (

← →

) to select "CALIBRATE YES" and confirm with the

key and start the calibration...

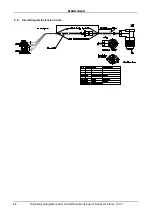

Figure 11: Charging Lifter

Charging lifter

Minimum

water level

Water level

By activating

treatment cycle

Chamber 2

SBR

Chamber 1

SS+ P

Air hose

red

KLARO GmbH

Original Operating Manual for KLARO Small Wastewater Treatment Plant V.15.07

25

Measurement in

progress

3 measurement processes are performed automatically

Enter current

fill

level: 000 cm

Enter the current level b of chamber 1, which you measured with a yardstick

(measured from the tank bottom to the water surface) and confirm with

.

Save?

____ cm No

The measure now specified is the distance

c

from the tank bottom to the inlet

point of the lifter. Use the arrow keys (

← →

) to select "Save Yes" and confirm

with the

key. The calibration is now complete and you can exit this menu

by pressing the "ESC" key.

2nd step: Setting the Control Parameters

Setting the control parameters for the level measurement is essential for proper functioning of the plant.

Please go through the following points carefully in order:

Service Code

Input

Go to the menu item "SERVICE CODE INPUT," press the

key and enter

the general service code when prompted.

Level Measurement

Setting

Use the left arrow (

←

) key to select "Level Measurement Setting" and confirm

with the

key.

Level

Start from: 000 cm

Enter the water level

b

, at which a treatment cycle is to be started. Confirm

with the

key.

Recirculation

2 min

Use the numeric keys to enter the value "2 min" and confirm with the

key. For plants that are very underutilised, we recommend entering a higher

value. The required settings are now complete and you can exit the menu by

pressing "ESC".

Warning Backwater

From: 000 cm

(from Software 8.29)

NOTE:

Enabling the backwater alarm is not mandatory for the correct

functioning of the plant. By saving the value 000 cm, this warning is disabled.

To enable, measure the height between the bottom of the tank and lower edge of the emergency

overflow in the partition or, for full cycle plants, at the drain.

3rd step: Functional check

The level measurement can now be performed in manual mode for testing purposes. To do so, the level

measurement must be switched on with number "1." The controller then automatically performs a

measurement. After the operation, the measured value appears.

6.1.3. Switching Off the Level Measurement

To turn off the level measurement and allow timed cycles to run again, the 2nd steps described above

must be repeated. The water level b must be set to 0 cm. Recirculation can remain set to 2 minutes.

6.1.4. Safety and Fault Messages

If the sensor measures a value below 40 mbar, the following message is displayed: "Malfunction: min.

level.“ In this event, the plant switches to normal timed operation. The reason for this fault is either a

water level that is too low (

≤ 40 cm) in the sludge storage/buffer or a leak in the pressure or measuring

line. We recommend to contact the manufacturer in this case.

KLARO GmbH

2

Original Operating Manual for KLARO Small Wastewater Treatment Plant V.15.07

IMPORTANT:

•

This Operating Manual contains information about the plant, from installation

to maintenance, and must therefore be read before commissioning of the

plant!

•

All safety instructions must be observed!

•

The Operating Manual must be kept readily available during the operation of

the plant!

Plant Specifications

For any questions in the course of the operation of the plant, the specifications of your plant should

be noted as follows. With the help of this information, our staff will be able to help you more quickly

in the event of a malfunction. The specifications can be found on the nameplate, which is located

on the outside of the cabinet door for indoor cabinets, and inside the cabinet for outdoor cabinets.

Small Wastewater Treatment

Plant

PT

Sludge storage

Buffer

SB-Reactor

Approval No.:

Process class:

Certified:

Cabinet:

Controller:

Compressor:

Denomination:

Serial No.:

Article No.:

Additional module:

Article No.:

El. Connected load:

KLARO GmbH

Original Operating Manual for KLARO Small Wastewater Treatment Plant V.15.07

3

CONTENTS

Page

1.

About this Operating Manual

6

1.1.

Original Language of Documentation

6

1.2.

Completeness

6

1.3.

Liability

7

2.

Safety

7

2.1.

Explanation of Warnings and Prohibitions

7

2.2.

Hazard statements

8

2.3.

Warnings

9

2.4.

Exclusion for Use

10

3.

Warranty

10

4.

Function of the SBR Plant

10

4.1.

Plants for carbon elimination (process classes C)

11

4.2.

Systems with Additional Nitrogen Removal (Process Classes N and D)

13

4.3.

Systems with Additional Phosphate Elimination (Process Class +P)

13

4.4.

Systems with Additional Sanitation (Process Class +S)

13

5.

Control of the Small Wastewater Treatment Plant

13

5.1.

Connections to the KL-controls (230V option for solenoid valves)

16

5.2.

Connections to the KL24 controller(24V option for stepper motor valves)

16

5.3.

Operating the Controller

18

5.3.1.

Querying Operating Hours

18

5.3.2.

Manual Control of the Valves and the Cabinet Fan in "Manual Mode"

19

5.3.3.

Setting Date/Time

20

5.3.4.

Set Holiday Mode

20

5.3.5.

Query Malfunctions - Query Old Malfunctions

21

5.3.6.

Display Settings

21

5.3.7.

Service Menu and Action Code

21

5.4.

Changing the Fuses

22

5.5.

Operation of Power Failure Detector

22

6.

Additional functions of the Controllers KLplus/ KL24plus and KLbasic/KL24base

23

6.1.

Underload detection (KLplus/KL24plus)

23

6.1.1.

Mode of Operation

24

6.1.2.

Commissioning

24

6.1.3.

Switching Off the Level Measurement

25

6.1.4.

Safety and Fault Messages

25

6.2.

Optional Functions

26

6.2.1.

Connection of an external alarm device

26

6.2.2.

Connection of a contactor for switching the compressor

26

6.2.3.

Connection of a UV reactor

26

6.2.4.

Phosphate precipitation with metering pump

26

7.

Maintenance, Repair and Operation

28

7.1.

Sludge Evacuation

28

7.2.

Operating Instructions

29

8.

Fault Messages and Troubleshooting

31

8.1.

Fault Message on the Display

32

8.2.

Unusual Water Levels - Troubleshooting

33

KLARO GmbH

2

Original Operating Manual for KLARO Small Wastewater Treatment Plant V.15.07

IMPORTANT:

•

This Operating Manual contains information about the plant, from installation

to maintenance, and must therefore be read before commissioning of the

plant!

•

All safety instructions must be observed!

•

The Operating Manual must be kept readily available during the operation of

the plant!

Plant Specifications

For any questions in the course of the operation of the plant, the specifications of your plant should

be noted as follows. With the help of this information, our staff will be able to help you more quickly

in the event of a malfunction. The specifications can be found on the nameplate, which is located

on the outside of the cabinet door for indoor cabinets, and inside the cabinet for outdoor cabinets.

Small Wastewater Treatment

Plant

PT

Sludge storage

Buffer

SB-Reactor

Approval No.:

Process class:

Certified:

Cabinet:

Controller:

Compressor:

Denomination:

Serial No.:

Article No.:

Additional module:

Article No.:

El. Connected load:

KLARO GmbH

Original Operating Manual for KLARO Small Wastewater Treatment Plant V.15.07

3

CONTENTS

Page

1.

About this Operating Manual

6

1.1.

Original Language of Documentation

6

1.2.

Completeness

6

1.3.

Liability

7

2.

Safety

7

2.1.

Explanation of Warnings and Prohibitions

7

2.2.

Hazard statements

8

2.3.

Warnings

9

2.4.

Exclusion for Use

10

3.

Warranty

10

4.

Function of the SBR Plant

10

4.1.

Plants for carbon elimination (process classes C)

11

4.2.

Systems with Additional Nitrogen Removal (Process Classes N and D)

13

4.3.

Systems with Additional Phosphate Elimination (Process Class +P)

13

4.4.

Systems with Additional Sanitation (Process Class +S)

13

5.

Control of the Small Wastewater Treatment Plant

13

5.1.

Connections to the KL-controls (230V option for solenoid valves)

16

5.2.

Connections to the KL24 controller(24V option for stepper motor valves)

16

5.3.

Operating the Controller

18

5.3.1.

Querying Operating Hours

18

5.3.2.

Manual Control of the Valves and the Cabinet Fan in "Manual Mode"

19

5.3.3.

Setting Date/Time

20

5.3.4.

Set Holiday Mode

20

5.3.5.

Query Malfunctions - Query Old Malfunctions

21

5.3.6.

Display Settings

21

5.3.7.

Service Menu and Action Code

21

5.4.

Changing the Fuses

22

5.5.

Operation of Power Failure Detector

22

6.

Additional functions of the Controllers KLplus/ KL24plus and KLbasic/KL24base

23

6.1.

Underload detection (KLplus/KL24plus)

23

6.1.1.

Mode of Operation

24

6.1.2.

Commissioning

24

6.1.3.

Switching Off the Level Measurement

25

6.1.4.

Safety and Fault Messages

25

6.2.

Optional Functions

26

6.2.1.

Connection of an external alarm device

26

6.2.2.

Connection of a contactor for switching the compressor

26

6.2.3.

Connection of a UV reactor

26

6.2.4.

Phosphate precipitation with metering pump

26

7.

Maintenance, Repair and Operation

28

7.1.

Sludge Evacuation

28

7.2.

Operating Instructions

29

8.

Fault Messages and Troubleshooting

31

8.1.

Fault Message on the Display

32

8.2.

Unusual Water Levels - Troubleshooting

33

25