Safety and Responsibility

3 --- 16

Extension or modification of the compressed air station

If a compressed air installation is to be extended or modified, check the blow ---off ca-

pacity of the pressure relief valves on air receivers and pipelines before installing the

new machines.

Pressure relief valves of insufficient blowoff capacity must be replaced by valves with a

higher capacity.

3.5.2

Safe machine operation

Here is found information to support safe conduct with the machine.

Transport

Use suitable lifting gear that conforms to local safety regulations.

Attach lifting gear only to the designated points on the machine.

Make sure the centre of gravity is correctly positioned to avoid the machine tipping.

Make sure the danger zone is clear.

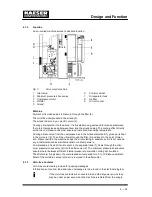

Installation

Make sure no power is applied when electrical connections are made.

Only use only electrical cables that are suitable and approved for the the loads ap-

plied.

Install or remove pressure lines only when they are in the depressurised condition.

Only use pressure lines that are suitable and approved for the maximum working pres-

sure and medium used.

Do not allow connecting pipes to be under mechanical stress.

Do not step onto machine components to climb up the machine.

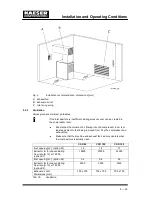

Location

Install the machine in a suitable room.

If installed outdoors, the machine must be protected from frost, direct sunlight, dust

and rain.

The machine is not explosion ---proof.

Do not operate in areas in which specific requirements with regard to explosion

protection are applied.

For instance, the requirements of the ATEX directive 94/9/EC ”Equipment and Protec-

tive Systems for use in Explosive Atmospheres”.

Ensure adequate ventilation.

Observe the required ambient conditions:

ambient temperature and humidity,

clean inlet air with no damaging contaminants,

inlet air free of explosive or chemically unstable gases or vapours,

inlet air free of acid ---forming substances, particularly ammonia, chlorine or hydro-

sulphide.

Do not position the machine in the warm exhaust air from other machines.

Ensure accessibility so that all work on the machine can be carried out without danger

or hindrance.

Operation

Keep the machine enclosure closed for safety and correct cooling function.

Summary of Contents for CSD 102

Page 2: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 95: ......

Page 96: ......

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ...Appendix 13 92 13 1 2 Pipeline and instrument flow diagram option C1...

Page 101: ......

Page 102: ......

Page 103: ......

Page 104: ......

Page 105: ......

Page 106: ...Appendix 13 98 13 1 3 Dimensional drawing 13 1 3 1 Air cooling option K1...

Page 107: ......

Page 108: ......

Page 109: ...Appendix 13 101 13 1 3 2 Water cooling option K2...

Page 110: ......

Page 111: ......

Page 112: ...Appendix 13 104 13 1 4 Electrical diagram...

Page 113: ......

Page 114: ......

Page 115: ......

Page 116: ......

Page 117: ......

Page 118: ......

Page 119: ......

Page 120: ......

Page 121: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 127: ......

Page 128: ......

Page 129: ......

Page 130: ......

Page 131: ......

Page 132: ......

Page 133: ......

Page 134: ......