Technical data

Page 46

4.5.2

Encoder connector [X2B]

The 15-pin D-SUB connector [X2B] can be used for the feedback of encoder-equipped motors. Possible incremental encoders

for the encoder connector can be divided into several groups. If you want to use other types of encoders, please contact your

sales partner.

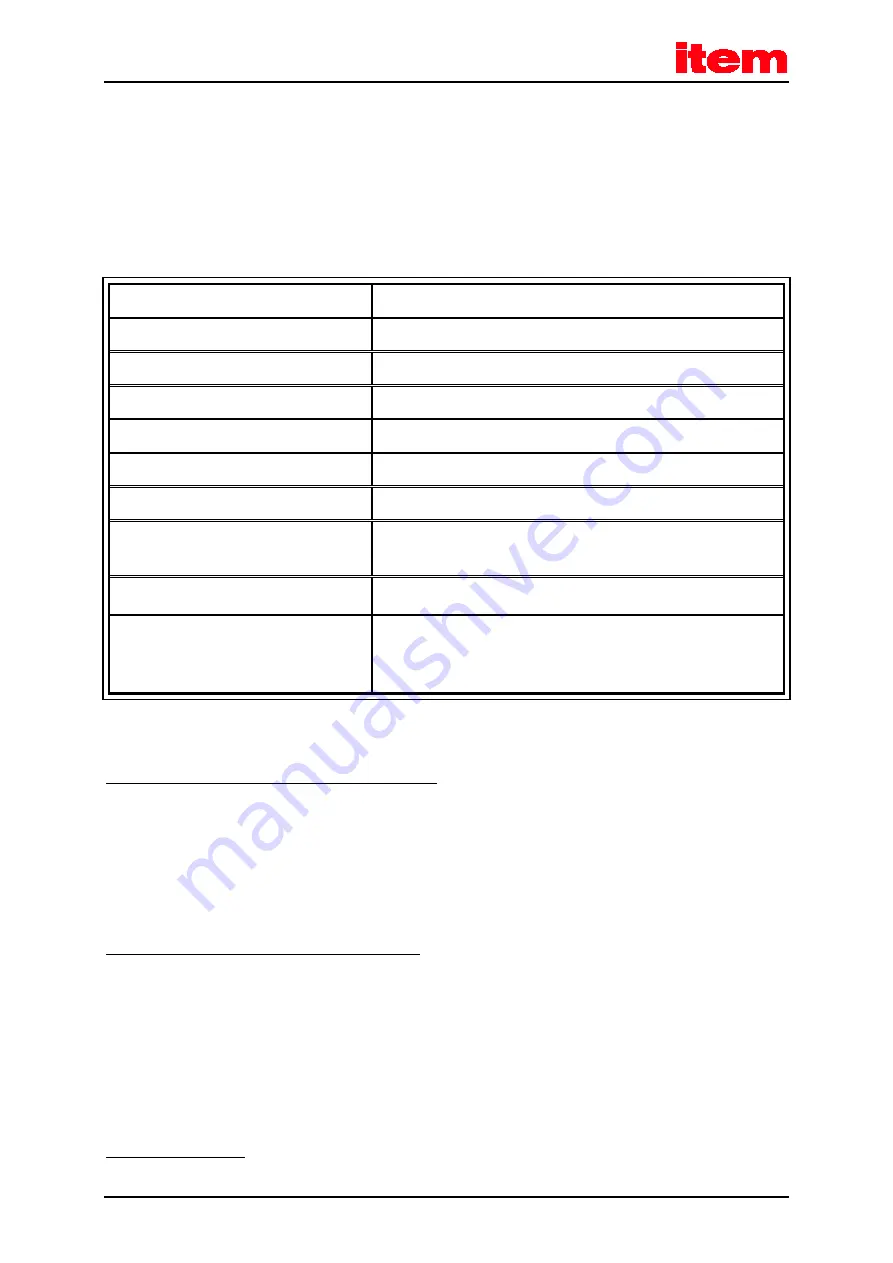

Table 20:

Technical data: encoder evaluation [X2B]

Parameter

Value

Parameterisable number of encoder lines

1 - 2

18

lines/revolution

Angular resolution/interpolation

10 bits/period

Track signals A, B

1 V

PP

differential; 2.5 V offset

Track signals N

0.2 to 1 V

PP

differential; 2.5 V offset

Commutation track A1, B1 (option)

1 V

PP

differential; 2.5 V offset

Track signal input impedance

Differential input 120

Ω

Limit frequency

f

limit

> 300 kHz (high-resolution track)

f

limit

approx.10 kHz (commutation track)

Additional communication interface

EnDat (Heidenhain) and HIPERFACE

®

(Sick-Stegmann)

Supply output

5 V or 12 V; 300 mA max; current-limited

Control via sensor lines

Setpoint programmable via SW

Standard incremental encoders without commutation signals:

This type of encoder is used for low-cost linear motor applications in order to save the costs for the provision of the

commutation signals (Hall sensor). With this type of encoder, the item Servo Positioning Controller C 3-Series must perform an

automatic pole position determination after power-on.

Standard incremental encoders with commutation signals:

This variant uses standard incremental encoders with three additional, binary Hall sensor signals. The line count of the

encoder can be parameterised as desired (1 to 16,384 lines/revolution).

There is an additional offset angle for the Hall sensor signals. It is determined during the motor identification process or it can

be set via the item Motion Soft

parameterisation software. Normally, the Hall sensor offset angle is zero.

Sick-Stegmann encoders: