Intel

®

Server System R1000WF Product Family System Integration and Service Guide

7

e)

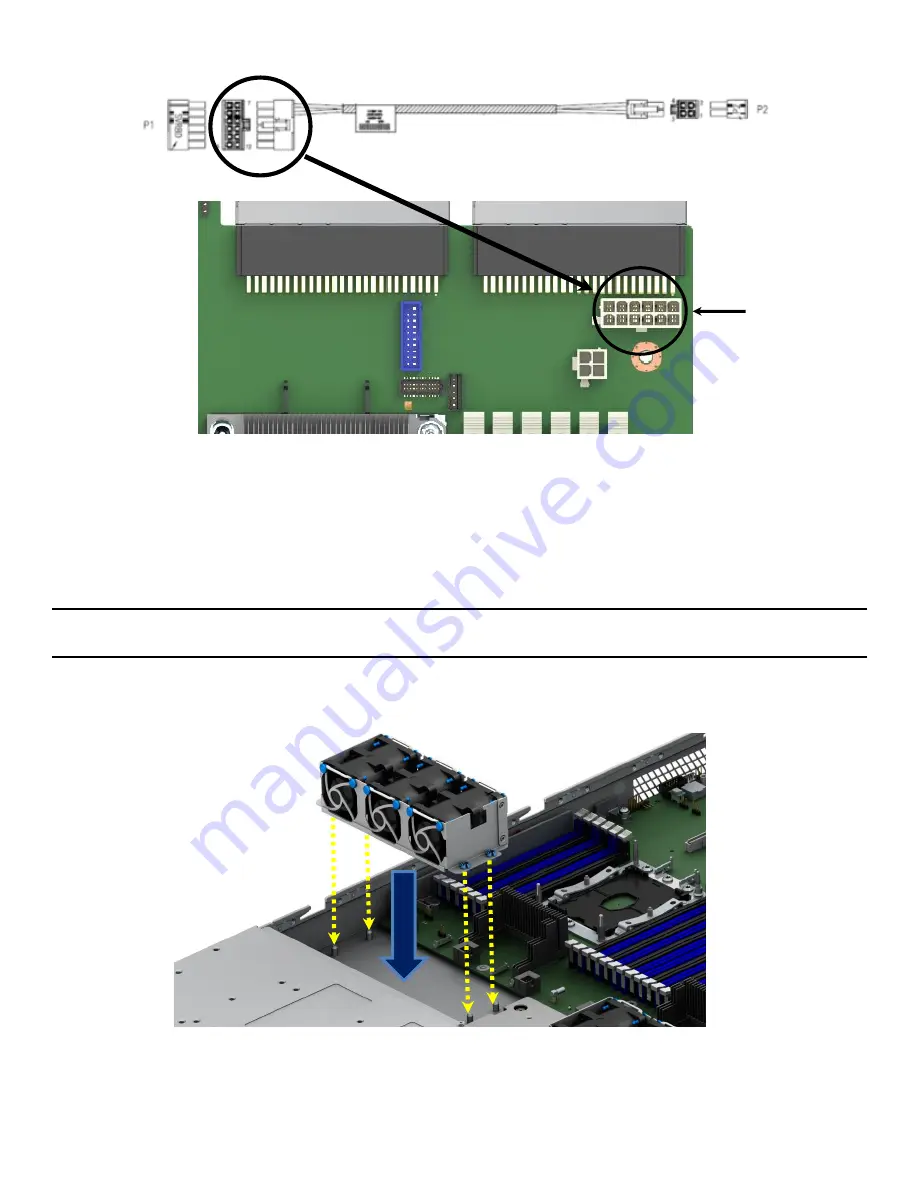

Locate the backplane power cable.

Figure 9. Hot Swap Backplane Power Cable and Onboard Connector

f)

Connect the 2x2 pin cable connector (labeled “P2”) to the matching power connector on the

backplane (silk screened “PWR”)

g)

Route the backplane power cable along the right chassis sidewall, to the area behind the power

supply bay and connect the 2x6 pin cable connector (labeled “SVRBRD”) to the matching 2x6 white

power connector on the server board (silk screened “HSBP PWR”)

Note:

Once the cable is attached on both ends, carefully press the cable as low as possible into the cable

routing channel.

3.

Install the system fan modules

Figure 10. System Fan Assembly Installation

a)

Align the fan assembly with mounting pins on the chassis base and push down until firmly seated

Hot Swap

Backplane

Connector