52

6.5 Push operation enable mode

This is an operation mode to perform operation by directly writing current limit value (%) and positioning width

for push in addition to direct designation of position data, acceleration and deceleration and speed into the

register of the PLC, and allows for control of a maximum 3 axes.

Further, it is always possible to read present position data.

Setting of position table for each axis is unnecessary.

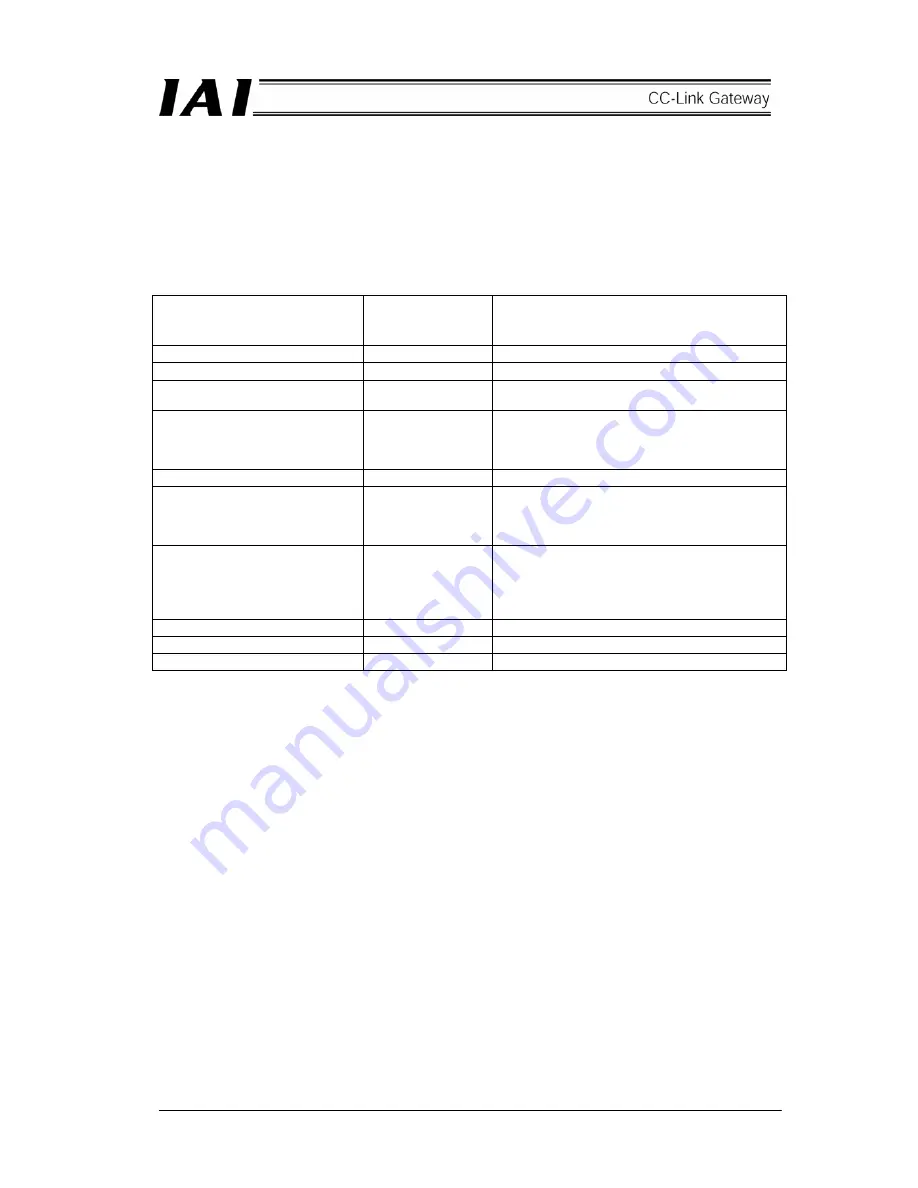

Primary functions controllable in this mode are as shown in the following table.

Primary functions

○

: Direct control

△

: Indirect control

×

: Ineffective

Remarks

Home return operation

○

Positioning operation

○

Speed, acceleration and

deceleration setting

○

Pitch (incremental) feed

△

Pitch feed data cannot be directly processed.

Give command by adding or subtracting data of

same moving amount to/from the present position

by host PLC.

Push operation

○

Speed change during movement

○

Speed data is accepted at start of positioning.

Therefore, if you attempt to change the speed in

process of movement, change the speed data

and restart during moving.

Operation in different acceleration

and deceleration

○

Acceleration and deceleration data is accepted at

start of positioning. Therefore, if you attempt to

designate deceleration different from

acceleration, change the acceleration and

deceleration data during movement and restart.

Pause

○

Zone signal output

△

Monitor the present position data by the PLC. (*)

PIO pattern selection

×

* There is no strobe signal in the present position data. Therefore, when checking the present position by

the PLC during movement, provide a range to check that there is data of 2 scans or more in the range.

Summary of Contents for RCM-GW-CC

Page 1: ...IAI America Inc CC Link RCM GW CC Gateway Unit Operation ManualFirst Edition...

Page 4: ......

Page 10: ...6 1 5 How to identify model RCM GW CC Basic model For CC Link Gateway unit...

Page 12: ...8 2 2 External dimension drawing Mounting dimension...

Page 78: ...74...

Page 82: ...78 Position data measurement value Present position 1 2 3 4 4 5 6 7...

Page 84: ...80 Speed acceleration and deceleration set value Actuator speed Speed n2 Speed n3 1 2 3...

Page 88: ...84 Command position No Completion position No 1 2 3 4 5 6...

Page 91: ...87...

Page 93: ...89...

Page 125: ...121 No 3 Axis 1 pause No 3 Axis 1 pause lamp No 3 Axis 1 STP...

Page 130: ...126...

Page 131: ......