61

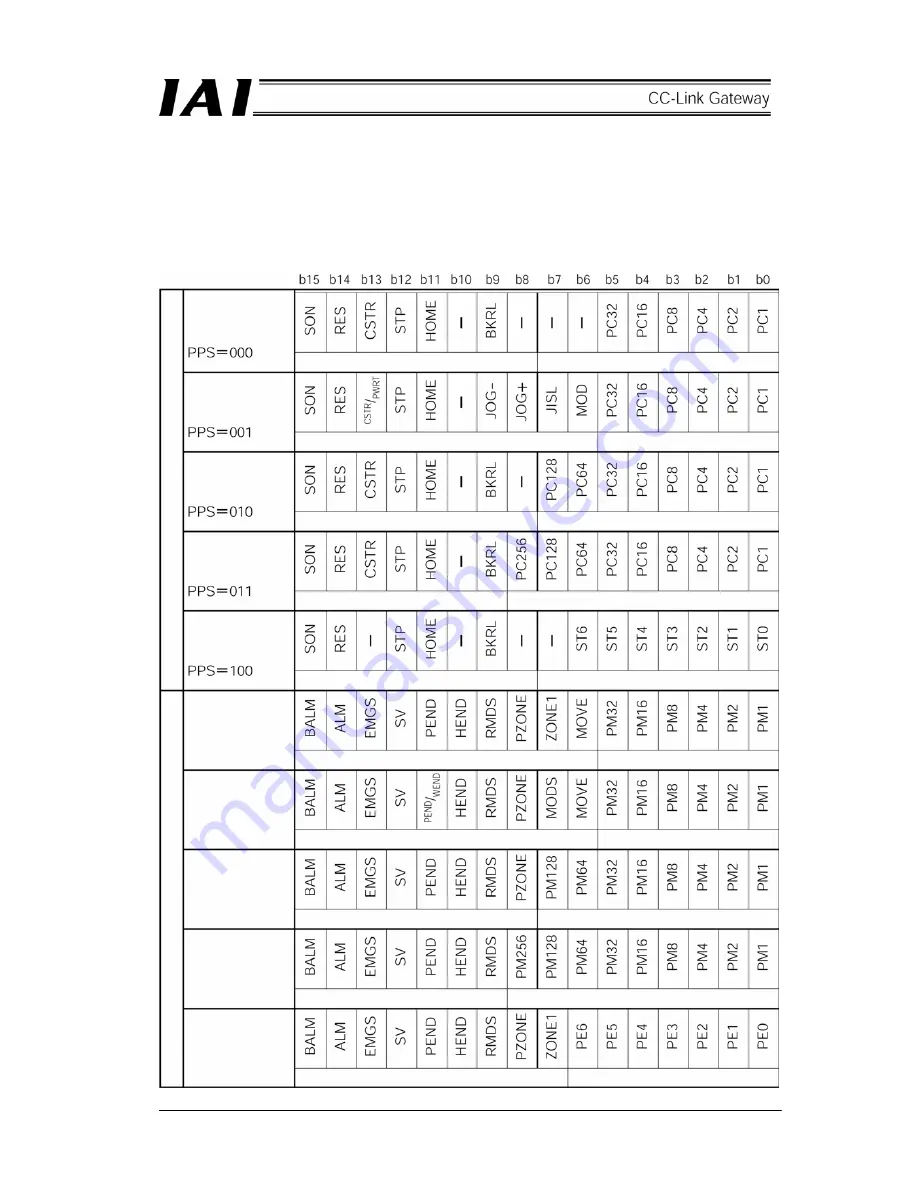

6.6.2 Assignment for each axis

Input and output signals for each axis position No. designated mode and those in simple direct value

mode are different from each other in size of region and its content. Further, in the position No.

designated mode, meaning of each bit depends on the pattern set by gateway control signal PPS.

(1) Control signal and status signal of position No. designated axis

Pattern 0

(Standard)

Pattern 1

(Teach)

Pattern 2

(Positioning 256

points)

Pattern 3

(Positioning 512

points)

Pattern 4

(Air cylinder)

PLC

outp

ut R

W

w

PLC

in

put R

W

r

Pattern 0

Pattern 1

Pattern 2

Pattern 3

Pattern 4

Control signal

Command position No.

Control signal

Command position No.

Control signal

Command position No.

Control signal

Command position No.

Control signal

Start position No.

Status signal

Completed position No.

Status signal

Completed position No.

Status signal

Completed position No.

Completed position No.

Status signal

Completed position No.

Status signal

Summary of Contents for RCM-GW-CC

Page 1: ...IAI America Inc CC Link RCM GW CC Gateway Unit Operation ManualFirst Edition...

Page 4: ......

Page 10: ...6 1 5 How to identify model RCM GW CC Basic model For CC Link Gateway unit...

Page 12: ...8 2 2 External dimension drawing Mounting dimension...

Page 78: ...74...

Page 82: ...78 Position data measurement value Present position 1 2 3 4 4 5 6 7...

Page 84: ...80 Speed acceleration and deceleration set value Actuator speed Speed n2 Speed n3 1 2 3...

Page 88: ...84 Command position No Completion position No 1 2 3 4 5 6...

Page 91: ...87...

Page 93: ...89...

Page 125: ...121 No 3 Axis 1 pause No 3 Axis 1 pause lamp No 3 Axis 1 STP...

Page 130: ...126...

Page 131: ......