2-53

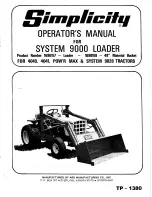

TWO SPEED CHANGE MECHANISM

When running at 1st speed (low speed)

Port B(High pressure)

Port C(Low pressure)

Valve plate(25)

Spring(42)

Spool(41)

Low pressure

Spring(20)

Swash plate control piston(19)

Face a

Swash plate(5)

Spring(9)

Piston

sub assy(15)

Face c

Face b

L1

L

0

Fp + Fs2

Pi1

Pi2

M1

M2

Steel ball(6)

F + Fs1

At 1st speed(low speed)

3)

R35Z72TM08

(1)

Swash plate (5) has three faces, from "a" to "c", as shown below in the figure and installed in the

flange holder that is piston motor housing with two steel balls (6) in the condition where it can be

tilted.

When the control valve is set to the 1st speed position, spool (41) is placed in the position shown

below in the figure by the force of spring (42), and the passage of swash plate control piston (19)

passes across the Pi1 and Pi2 port positions and led to the tank port. Therefore, the force pushing

up the swash plate control piston (19).

Fp : Swash plate control piston thrust

Ap : Swash plate control piston pressure receiving area

P : Pressure

Fp = (Ap

Ý

P) = 0

When steel ball (6) is placed on the tilting center, the balance of moment acting on swash plate (5)

is in the condition of (

Į

F+Fs1)

Ý

L1 > (Fp+Fs2)

Ý

Lo depending on the total

Į

F of driving force of

piston sub assy (15) and the force of spring (9) Fs1 and Fs2, then swash plate (5) stables at the

face a and the swash plate angel is

ɷ

, and consequently the motor speed corresponding to the 1st

speed, low speed, is obtained.

(

(

Į

F+Fs1)

Ý

Ý

L1 > (Fp+Fs2)

Ý

Lo