IDS2000 Dual-Row Aisle Containment

Installation Guide (Split-type Skylight, Old-Version

Sliding Door)

3 Installation Scenarios in Dual Row Aisle Containment

Issue 02 (2015-06-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

37

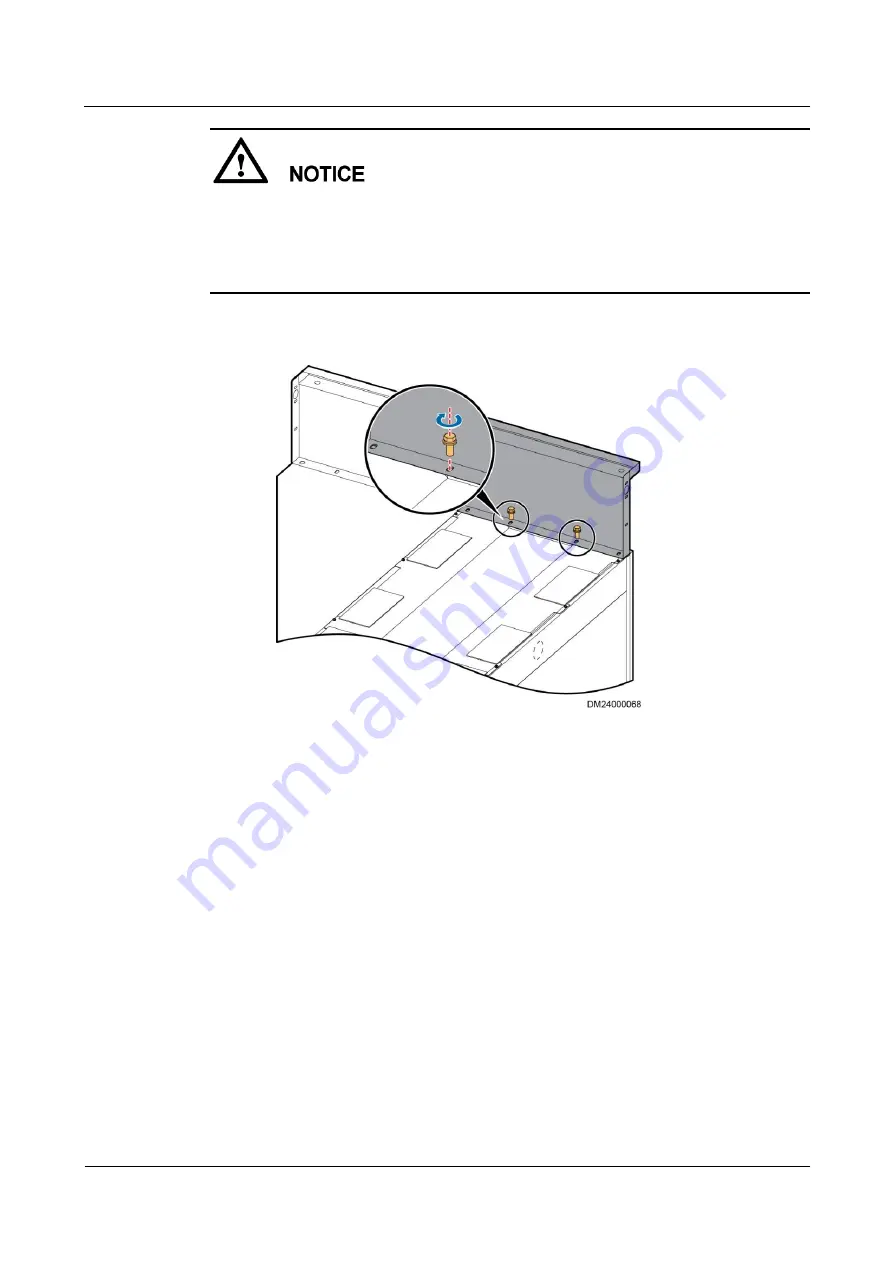

When securing the skylight connective plate to the cabinet, partially tighten the screws so

that you do not have to remove the screws if the skylight cannot be accurately mounted.

Fully tighten the screws after the skylight is accurately mounted.

Align the center of the skylight connective plate with the cabinet center. The plate surface

and the front beam of the cabinet should be on the same level.

Figure 3-8

Installing a skylight connective plate at the top of air conditioner or UPS

cabinets

2.

Secure the adjacent skylight connective plates using M6 screws and nuts, as shown in