of the bottom wing panel on the leading edge

and the center of the fuselage at former F3.

Center the wing in the fuselage, aligning the marks.

❏

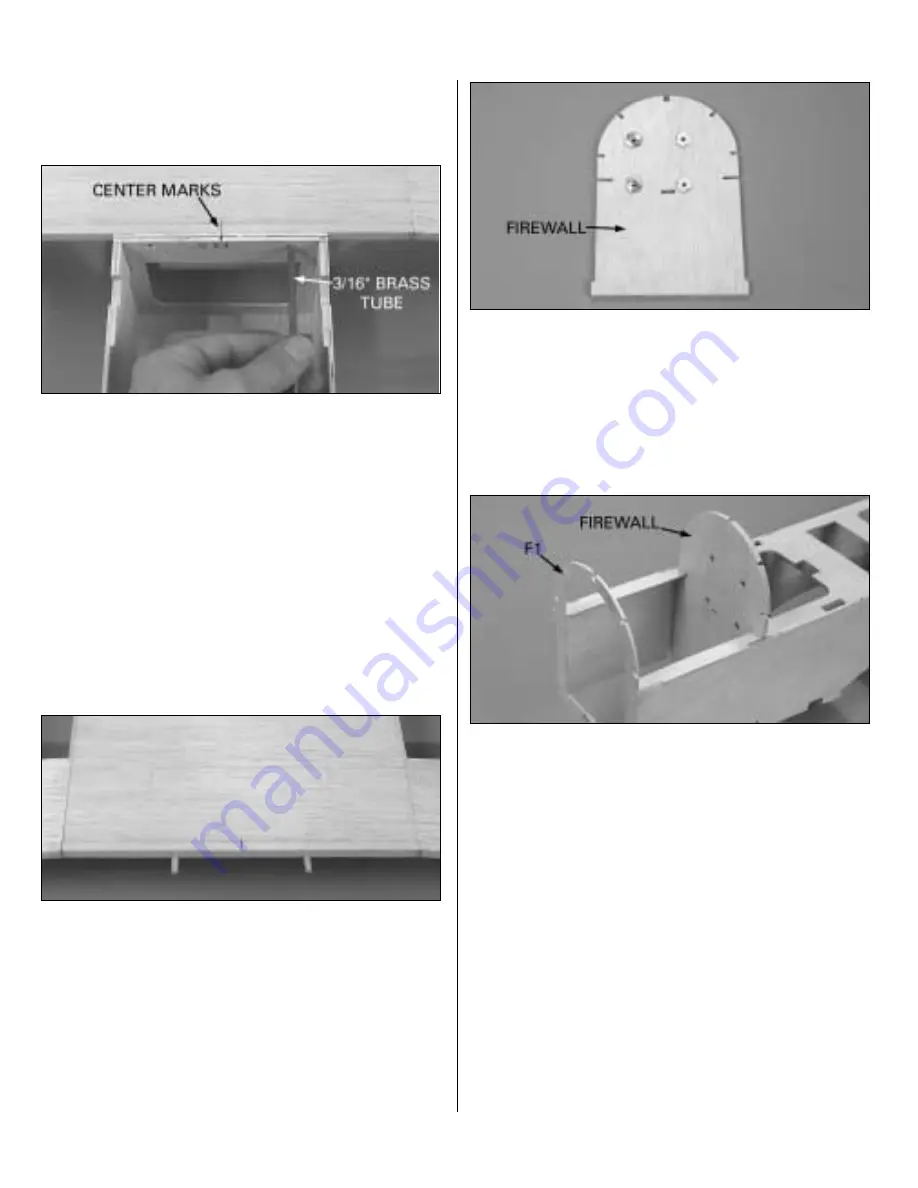

15. Using the holes in F3 as a guide, use a

3/16" [4.8mm] brass tube sharpened on the end

to cut holes through the balsa leading edge of

the wing for the wing dowels. (To sharpen the

end of a brass tube, use a rotary tool with a

cutoff wheel or a file to bevel the outside of the

tube, and use a #11 hobby knife to bevel the

inside of the tube.)

❏

16. Remove the wing from the fuselage. Use

the brass tube or a 3/16" [4.8mm] drill to drill

holes the rest of the way through the wing and

into the shear webs inside.

❏

17. Round one end of both 3/16" [4.8mm]

wing dowels. Without using any glue, fit the

dowels into the wing, then test fit the wing to

the fuse.

Do not

glue the dowels into the wing

until instructed to do so.

❏

18. Glue both die-cut 1/8" [3.2mm] plywood

formers F2

together. From now on this

assembly will be referred to as the

firewall

.

❏

19. Drill 13/64" [5.2mm] holes through the

four punchmarks in the front of the firewall.

Insert four 8-32 blind nuts into the holes in the

back of the firewall and lightly tap them in with

a hammer. Carefully add a few drops of thin CA

around the nuts to permanently hold them in.

❏

20. Glue the die-cut 1/8" [3.2mm] plywood

former F1

to the front of the fuselage.

❏

21. Fit the firewall into position. Note the

angle on the front of the fuse top where it

contacts the firewall to provide the correct

amount of right thrust. Glue the firewall into the

fuselage with 30-minute epoxy using clamps

where necessary to securely hold it into position.

❏

22. Sand the bottom of former F3 and the

firewall even with the bottom of the fuse sides.

Glue the fuselage top to the fuselage sides from

F3 forward.

28

Summary of Contents for Dynaflite S.E.5a

Page 9: ...9 Die Drawing...

Page 10: ...10 Die Drawing...