26

EN

5.

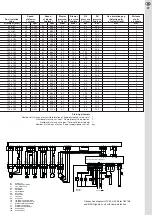

Basic adjustment table

6

Wiring diagram

Revolutions per minute

HRG 134

RG 148

Maximum rpm, n

max

8220 rpm

8520 rpm

Pre-purge speed n

prp

75%

60%

Offset ignition speed rpm o

i

by -3%

by -8%

Offset flame stabilisation speed rpm o

fs

by -2%

by -4%

Post-purge speed n

pop

75%

75%

Turn-on speed V2 n

on,V2

60%

68%

Turn-off speed V2 n

off,V2

60%

75%

Factory Parameter

Times

Time of pre-purge, t

prp

5 sec.

Pre-ignition time, t

pri

10 sec.

Safety time, t

S

5 sec.

Flame stabilisation time, t

fs

15 sec.

Post-ignition time, t

poi

3 sec.

Post-purge time, t

pop

120 sec.

Firing

Firing

Start

Oil mass

Oil mass

output

output

1st/2nd

flow

flow

Burner model

1st level

2nd level

level

Blower

Oil nozzle

1st level

2nd level

Air nozzle

Burner tube

kW

kW

USgal/h 80° H

kg/h

kg/h

Ø mm

Ø mm

HLZ 45 AV 17 G1

10

18

2

HRG 134

0,30

0,84

1,52

17,50

80

HLZ 45 AV 17 G1

13

20

2

HRG 134

0,35

1,10

1,69

17,50

80

HLZ 45 AV 17 G1

13

22

2

HRG 134

0,35

1,10

1,85

17,50

80

HLZ 45 AV 19 G1

14

24

1

HRG 134

0,40

1,18

2,02

19,00

80

HLZ 45 AV 19 G1

16

26

1

HRG 134

0,45

1,35

2,19

19,00

80

HLZ 45 AV 19 G1

16

28

1

HRG 134

0,45

1,35

2,36

19,00

80

HLZ 45 AV 19 G1

16

30

1

HRG 134

0,45

1,35

2,53

19,00

80

HLZ 45 AV 22 G1

20

32

1

HRG 134

0,55

1,69

2,70

22,00

80

HLZ 45 AV 22 G1

20

34

1

HRG 134

0,55

1,69

2,87

22,00

80

HLZ 45 AV 22 G1

20

36

1

HRG 134

0,55

1,69

3,04

22,00

80

HLZ 45 AV 24 G1

26

38

1

HRG 134

0,60

2,19

3,20

24,00

80

HLZ 45 AV 24 G1

26

40

1

HRG 134

0,60

2,19

3,37

24,00

80

HLZ 45 AV 24 G1

26

42

1

HRG 134

0,60

2,19

3,54

24,00

80

HLZ 45 AV 24 G2

27

44

1

RG 148

0,65

2,28

3,71

24,00

80

HLZ 45 AV 24 G2

27

46

1

RG 148

0,65

2,28

3,88

24,00

80

HLZ 45 AV 24 G2

27

48

1

RG 148

0,65

2,28

4,05

24,00

80

HLZ 45 AV 24 G2

29

50

1

RG 148

0,75

2,45

4,22

24,00

80

HLZ 45 AV 24 G2

29

52

1

RG 148

0,75

2,45

4,38

24,00

80

HLZ 45 AV 24 G2

33

54

1

RG 148

0,85

2,78

4,55

24,00

80

HLZ 45 AV 24 G2

33

56

1

RG 148

0,85

2,78

4,72

24,00

80

HLZ 45 BV 27 G2

35

58

1

RG 148

0,85

2,95

4,89

27,00

100

HLZ 45 BV 27 G2

35

60

1

RG 148

0,85

2,95

5,06

27,00

100

HLZ 45 BV 27 G2

39

62

1

RG 148

1,00

3,29

5,23

27,00

100

HLZ 45 BV 27 G2

39

64

1

RG 148

1,00

3,29

5,40

27,00

100

HLZ 45 BV 27 G2

39

66

1

RG 148

1,00

3,29

5,56

27,00

100

HLZ 45 BV 31 G2

48

68

1

RG 148

1,10

4,05

5,73

31,00

100

HLZ 45 BV 31 G2

48

70

1

RG 148

1,10

4,05

5,90

31,00

100

HLZ 45 BV 31 G2

48

72

1

RG 148

1,10

4,05

6,07

31,00

100

HLZ 45 BV 31 G2

48

74

1

RG 148

1,10

4,05

6,24

31,00

100

HLZ 45 BV 31 G2

50

76

1

RG 148

1,25

4,22

6,41

31,00

100

HLZ 45 BV 31 G2

50

78

1

RG 148

1,25

4,22

6,58

31,00

100

HLZ 45 BV 31 G2

50

80

1

RG 148

1,25

4,22

6,75

31,00

100

HLZ 45 BV 31 G2

50

82

1

RG 148

1,25

4,22

6,91

31,00

100

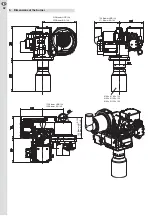

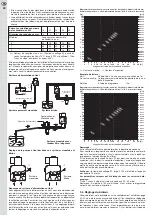

Connecting plan HLZ 45 with Elster CM 168

V1

yellow/green

bl

au

b

rown

b

rown

bl

ue

bl

ue

black

1

2

Elster CM 168

N

FL

N

L1

B1

Oil firing unit

EE

External remote unlocking

F1

Fuse, maximum 10A

GM Blower

motor

H1 Signal

failure

H2 Signal

operation

HS Main

switch

LD Flame

detector

OFV Oil

pre-heater

P1 Time

meter

PM Pump

motor

TB

Temperature or pressure limiter

TR

Temperature or pressure governor

TT Ignition

unit

V1

Solenoid valve, first stage

V2

Solenoid valve, second stage

Y4A

Euro plug (4-pin)

Y5A

Euro plug (7-pin)

B1

L1

LD

b

rown

TT

1

2

3

M

bl

ue

b

rown

yellow/green

GM

1

2

3

4

5

black

green

yellow

B4 S3 T2 T1 N

L1

Y5

N

1/N, PE 230V 50Hz

L1

PE

N

Y5A

HS

F1

TB

L1

N

T1

T2

S3

B4

Connections

By customer

J

P

TR1

J

P

L1

T8 T7

B5

T6

2

3

T6

T7

T8

J

P

TR2

B5

Y4

Y4A

V2

yellow/green

bl

ue

b

rown

1

2

1

2

3

N

bl

ue

b

rown

yellow/green

PM

L1

Hall PWM GND

X6

X1

PE

1

4

X4

X9

X7

PE

PE

X8

Bus-

X5

Bus+

N

L1

Y1

PE

Bus-

Bus+

1

2

EE

1

2

H1

H2

h

P1

Y3

Y3A

Bus+ Bus- communication interface (CI)

Y2

yellow/green

4

3

2

1

b

rown

bl

ue

black

OFV

N

DI

L1

X2

PE

NV1 NV2

L1

X13

PE

Connection diagram HLZ 45 with Elster CM 168

and optical flame monitor

BST solutions KLC 2002