21

EN

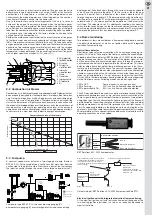

In order to achieve an intensive recirculation of flue gas over the entire

performance range in combination with a high stability of the flame the

combustion air is supplied in a swirled jet. The image below shows

schematically the mode of operation of the mixing device. The combus-

tion air enters through a nozzle into the flame tube.

Due to the rapid cross-sectional enlargement of the air jet a vacuum

accrues at the edge of the air nozzle through which the hot flame gases

are transported from the inside of the flame conduit into the evaporating

zone. Besides this, cooled flue gases reach through openings of the flame

tube from the combustion chamber into the evaporating zone. In addition,

a backward zone is developed in the flame’s rotation centre due to the

swirled flow of the combustion air.

Besides the avoidance of soot formation the intensive return of flue gases

to the flame’s root also achieves a reduction of nitrogen oxide emissions

(NOx). Two mechanisms essentially help this occur. On the one hand the

oxygen partial pressure of the mixture is reduced. Therefore the local con-

centration of dissociated oxygen molecules that react with the nitrogen

of the combustion air to NOx is reduced. On the other hand the flame

temperature is reduced through the recirculating flow of inert flue gases

with a higher specific heat capacity (CO

2

and H

²

O).

A Swirl generator

B Ignition electrode

C Air nozzle

D External re-

circulation zone

E Internal re-

circulation zone

F Flame

G Flame tube

H Injection nozzle

I Oil preheater

K Air

2.2 Combustion air blower

Combustion air is delivered through a speed regulated EC blower that has

been especially designed for the requirements of modern blue flame bur-

ners. It mainly distinguishes itself by high pressures and an extremely high

stiffness of pressure at low revolutions. Therefore it allows a pulsation-free

start of the burner even at high furnace back-pressure. In connection with

the especially developed silencer at the blower’s entry the smoothness of

running ensures a pleasantly low operating noise level of the burner. In

comparison with conventional blower solutions the high degree of effecti-

veness results in a clear reduction in electric energy consumption.

2.3 Fuel pump

A constant speed motor actuates a two-stage gear pump (Danfoss,

BFP 52 E L3). This pump delivers a continuous fuel mass flow from the

suction side to the pressure side. From there, a part of the fuel reaches

the injection nozzle through the current-less closed solenoid valve V1.

H

I

G

C

K

A

D

E

B

F

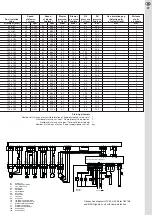

Characteristic curves of the blowers

0

5

10

15

20

25

30

35

40

0

20

40

60

80

100

120

140

160

180

20

Air volume flow in m

3

/h

Pressure in mbar

ebm-papst HRG 134

ebm-papst RG 148

Another partial flows back again through the current-less open solenoid

valve V2 and the pressure regulator P1 to the suction side of the gear

pump. This partial flow is redirected at the closed solenoid valve V2

through the pressure regulator P2. Depending on the valve’s position eit-

her the pressure regulator P1 or the pressure regulator P2 is active. The

solenoid valve V1 is under current for the operation of the burner in the

first stage. The solenoid valve V2 is additionally supplied with current to

switch into the second stage. In order to achieve a correct function of this

switching the adjusted pressure at the pressure regulator P2 must always

be beyond the pressure that has been set at pressure regulator P1.

2.4 Flame monitoring

Two optional systems are available as a flame-monitoring device, namely

an optical flame detector, as well as an ignition device with integrated

ionisation flame monitoring.

Optical flame detector

Real flames release luminous radiation with an unsteady changing fre-

quency. This kind of “flickering“ of the flame is used for the especially de-

veloped optical flame detector (BST Solutions KLC 2002) for blue flame

burners to recognise flames. The evaluation of the optical signal, as well

as the conversation into an evaluated signal, occurs through a micro pro-

cessor based control that is integrated into the flame detector. This flame

detector differs from other optical flame monitoring devices in that it eva-

luates only the flickering of the flame. The constant luminous radiation of

the glowing recirculation tube or other components inside the combustion

chamber is completely cut out. A radiation with constant frequency also

leads to no flame detection. It is not necessary to adjust the sensitivity.

Only an LED in the flame detectors housing indicates the current operating

state of the flame sensor. Following modes can be distinguished:

LED is OFF:

Flame monitor is carrying no current

LED is flashing:

KLC is active, no flame has been detected

LED is permanently ON:

KLC is active, flame has been detected

The LED may additionally be used as an optical interface to read different

performance parameters (such as e.g. pulse counter, visualisation of the

flame’s signal intensity, serial number). In order to prevent, at very extreme

energy densities, that the characteristic flickering signals of the flame will

be interferred by the emitting radiation of the recirculation tube and other

glowing components, an optical filter precedes the real light sensor. It

dims the appearing radiation in the background in a partial region of the

spectrum so that the usable flame signal appears comparatively stronger.

Misinterpretations that under extreme conditions can also lead to unsafe

operating conditions are also avoided.

BST Solutions KLC 2002 flame detector.

Output wiring of BST Solutions KLC 2002 flame monitor/Beru ZTÜ.

Electrical ignition unit with integrated ionisation flame monitoring

At the electrical ignition unit with ionisation flame monitoring one of the

two existing ignition electrodes is used as an ionisation electrode to

monitor the flame.

Accumulation of cables

Blue

Black

Brown

LED

Black, opto-coupler, FL

Brown, power supply, L1

Blue, N

Brown, power supply, L1

Black, opto-coupler, FL

“Digital signal“

When applying the voltage:

- Flame OFF, no potential, “high“

- Flame ON, “low“

With the alternating voltage at FL the signal is

rectified through the transistor, and the diode

is connected in series as well (to enable a

connection to the burner control unit with ionisation

flame monitoring).

Blue, N

Signal

Electronic strobe

Flame sensor

Series resistor to protect the transistor

Electronic control

at the flame

sensor

Fuel pump, type BFP 52 E L3, injection pressure gauging (P),

prime pressure gauging (V), pressure regulator first and second stage.

Pressure side

Suction side

Return side

V1

V2