27

The burner must be connected in accordance with DIN 4791:1985-09

using a 7-pole Euro plug. Wiring details are provided in the wiring diagram

in chapter 6. The factory will deliver the burner together with the Euro

connector (female plug). The Euro connector male plug is not included in

the scope of delivery. For burners with cover hood, the cables are inserted

through a rubber grommet in the base plate, where the oil tubes are

inserted as well.

3.3 Combustion chamber - minimum dimensions

In order to ensure reliable operation and low pollutant emissions, the

geometry of the combustion chamber must meet the test flame tube

standards according to DIN EN 267:2011-11.

3.4 Exhaust gas system

The burner is designed for operation dependent on ambient air as well as

for operation independent of ambient air. For operation dependent on am-

bient air we recommend the installation of a draft limiter into the flue gas

system in order to ensure constant pressure in the combustion chamber.

The low pressure in the combustion chamber which can be adjusted on

the draft limiter should be –0.1mbar compared to the ambient pressure.

The flue draft to be adjusted for overpressure boilers is provided in the

boiler manual.

For operation independent of ambient air, the burner can be connected

to the air exhaust separator of an air exhaust system using optional air in-

take connection pieces (Ø 50mm and Ø 80mm). For operation indepen-

dent of ambient air, no draft limiter may be installed into the exhaust pipe.

Furthermore, you must ensure that the heating boiler used is suitable for

the selected exhaust gas system with regard to exhaust gas composition

and exhaust gas temperatures.

The relevant applicable local provisions regarding the exhaust gas system

must also be taken into consideration.

3.5 Oil supply system, oil pipe dimensions

The burner can optionally be operated as a pure one-line system, a one-

line system with filter-aspirator combination (the pump is operated simi-

larly to a two-line system), or a two-line system.

The burner is preset for a two-line system as a standard. When converting

the pump to one-line operation, make sure to seal the return piece with a

sealing plug and remove the shift screw in the junction canal between the

pressure and intake side.

In order to avoid any malfunction of the burner caused by the oil supply

system, we recommend operating the burner in a pure one-line system

with filter-aspirator combination. The following points should be con -

sidered:

• Maximum intake height without booster pump: 3.5m

• Up to a nominal thermal output of the boiler of 50kW, we recommend

an oil pipe with an internal diameter of 4mm for the one-line system

with filter-aspirator combination.

• The pipes should be arranged such that the boiler together with the bur-

ner can be swiveled out by 90°.

• Upstream of the flexible oil pipes, you must install a valve at the end of

the rigid oil pipe (already integrated in commercial filter-aspirator com-

binations).

• A filter-aspirator combination must be installed upstream of the burner.

Insert of sintered plastic 20-75 μm for boiler capacities of up to 40 kW,

for boiler capacities >40 kW sieve with 100-150 μm of fineness.

• The highest point of the oil pipe should not exceed 3.5m above the end

of the intake pipe of the tank.

• The pipes must be installed in such a manner that no liquid may be

allowed to escape (raise) from the container.

• If the highest level of the fuel in the oil tank is above the oil pump of the

burner, you must install an anti-lifter valve at the highest point of the oil

pipe and as close as possible to the oil tank.

• The oil pipe and the connection to the burner must meet the current

provisions. It is absolutely imperative that you check the existing oil

supply as from the time of oil tapping from the oil tank.

Combustion chamber minimum dimensions according to

DIN EN 267:2011-11

Oil flow

Diameter or

Depth from the

height and width

baffle plate

1.0 - 2.0 kg/h

Ø 225 mm

250 - 350 mm

2.0 - 6.0 kg/h

Ø 300 mm

350 - 612 mm

* H = max. intake height in m (low sulphur fuel oil EL, oil temperature

>10 °C, up to 700 m above sea level, 1 filter, 1 check valve, 6x 90 °

bends).

For other system requirements (intake height, pipe lengths and nominal

thermal output of the boiler), you should consider the following diagrams

for pipe dimensioning.

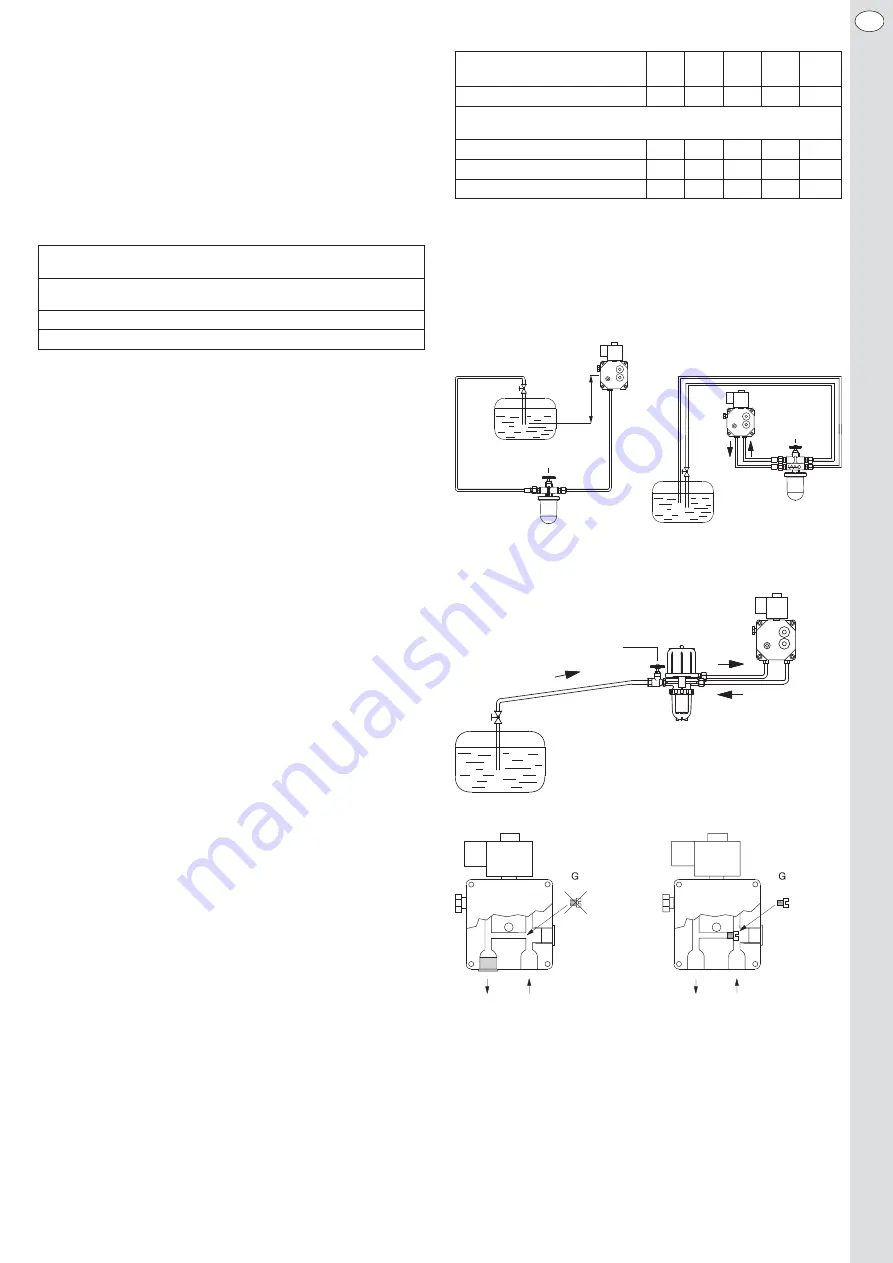

Oil supply system

One-line system Pure two-line system

One-line system with filter-de-aerator combination

Setting at the fuel pump for one-line and two-line system

Absperreinrichtung

Filter-Entlüfter -

Kombination

Einstrang-

system

Zweistrang-

system

Absperreinrichtung

Filter

Absperr-

einrichtung

Filter

H

max

=

3,5 m

EN

Nominal thermal output of the

boiler in kW

16

20

25

35

50

Internal pipe Ø in mm

4

4

4

4

4

H* in m

max. zulässige

Leitungslänge in m:

0

30

30

30

30

20

1

30

30

30

23

15

2

30

28

23

16

10

Valve system

Valve system

Valve system

One-line

system

Two-line

system

Filter-de-aerator

combination

Summary of Contents for HL 60 ALV.2

Page 15: ...15 DE 7 Explosionszeichnung mit Ersatzteilliste...

Page 20: ...20 DE 9 Brennerabmessungen HL 60 ALV 2 BLV 2 Schiebeflansch HL 60 ALV 2 BLV 2 Unitflansch...

Page 33: ...33 EN 7 Expanded view with spare parts list...

Page 38: ...38 EN 9 Burner dimensions HL 60 ALV 2 BLV 2 sliding flange HL 60 ALV 2 BLV 2 unit flange...

Page 51: ...51 FR 7 Vue clat e avec liste des pi ces de rechange...

Page 69: ...69 IT 7 Disegno esploso con elenco parti di ricambio...