-RA -91

LAYOUT

2

2

-E

21_E O901

Saving

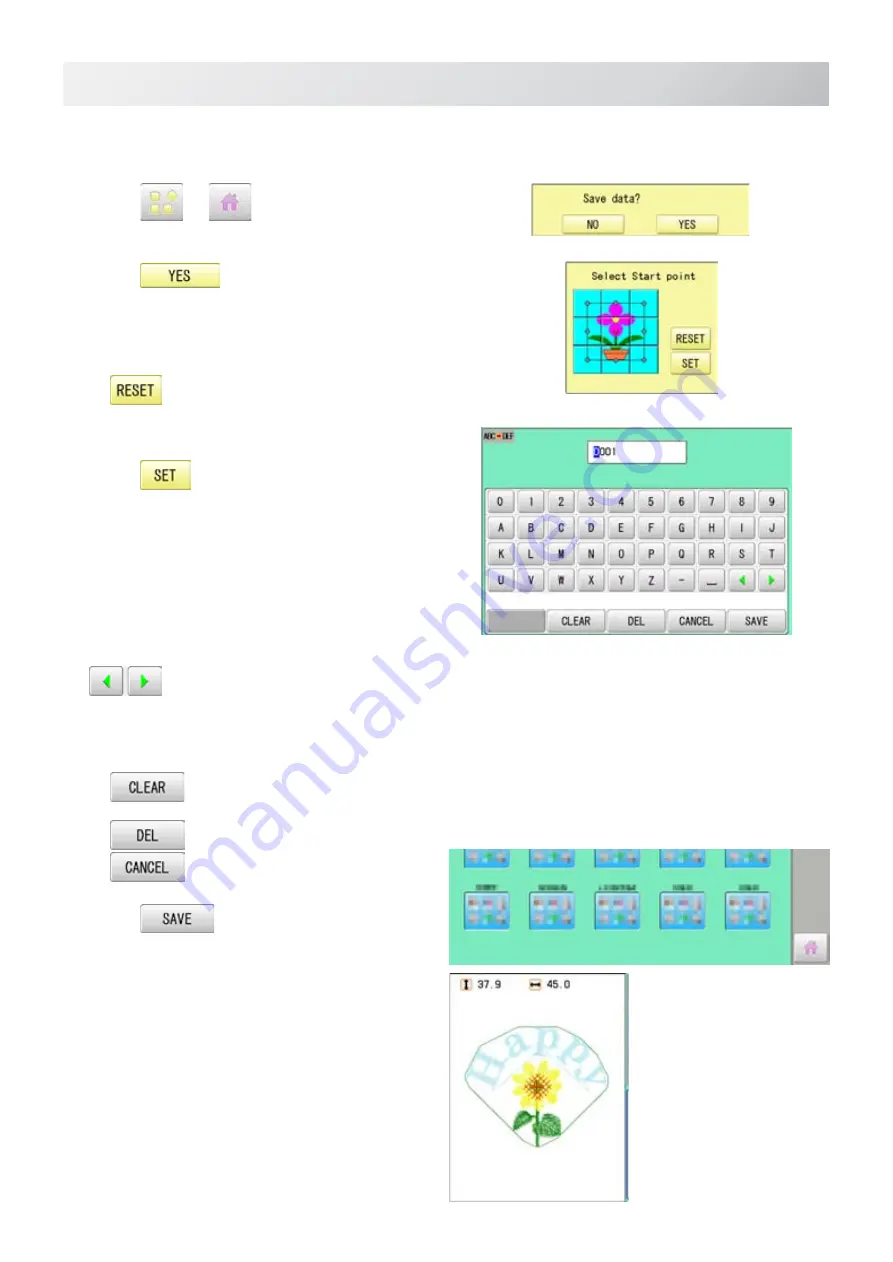

Save the laid pattern data.

14.Press

or

.

15.Press

.

Select start point of embroidery from 9 preset

points which are located around or center of the

pattern.

The start point of first selected pattern will

be set as the start point of combined

deign.

16.Press

.

Saving pattern name is displayed.

17.Go on to next step, if the pattern name is

not to be changed.

When you would like to change the letters,

select each digit in the existing name with

.

Then select each digit in the existing name.

Select word.

The maximum number of characters in a design

name is eight letters or numbers.

All the letters and/or numbers are

deleted.

Selected letter or number is deleted.

Renaming is cancelled.

18.Press

.

The new design is saved and the display return to

Menu mode or Drive mode.

Summary of Contents for HCD3E

Page 1: ...Industrial Single head Embroidery Machine INSTRUCTION BOOK Program Ver 2 23 HCD3E DEUC01 4 ...

Page 2: ......

Page 141: ... D2 117 13 6 FRAME CONFIRMATION 20_5 NB01 11 Press Press to return to Drive mode ...

Page 264: ... RA 110 26 3 BUILT IN FONT LIST 26_3 P401 Basic script Diacritic script ...

Page 265: ... RA 111 26 3a BUILT IN FONT LIST 26_3a P401 ...

Page 268: ......

Page 307: ......

Page 321: ......

Page 361: ......