IV.

PREPARING TO OPERATE

TREAD WIDTH CONTINUED

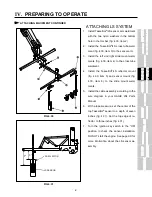

8. To adjust the tread out, place a suitable

prying tool under the center of the tire and

pry out at the same time that you push out at

the top of the leg (fig. 4.6). Carefully lower

the detasseler to the ground which, in turn

will allow the leg to slide outward. Repeat

the procedure until the desired tread is

obtained.

9. To adjust the tread in, raise the detasseler

until the tires on the side being adjusted are

just off the ground. Carefully lower the

detasseler which, in turn will allow the top of

the leg to slide in on the mainframe.

10. Retighten leg mounting bolts following the

torque specs and sequence on page XX.

11. Retighten the leg brace lock nut.

12. Repeat the above procedures to adjust and

set the opposite side legs. When finished, all

four legs should be the same distance from

x

FIG 4.6

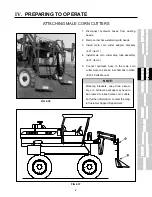

FIG 4.7

B

B

B

B

A

A

DIM A (FIG 4.7) DIM B (FIG 4.7)

120”

=

25.5”

114”

=

22.5”

108”

=

19.5”

Tread Width

(Standard)

DIM A (FIG 4.7) DIM B (FIG 4.7)

90”

=

10.5”

84”

=

7.5”

78”

=

4.5”

Tread Width

(Narrow Tread Option)

Summary of Contents for 204

Page 133: ...x IX TROUBLE SHOOTING TASSELTROL LS SYSTEM ELECTRICAL CONTINUED FIG 9 1 1 2...

Page 134: ...x IX TROUBLE SHOOTING NOTES...

Page 140: ...138 NOTES...

Page 141: ...x...