EN

29

User manual

WF 35

Translation of the original

instructions

PROCESS SETTINGS

Settings

Settings

Welding process

Standard

Smooth current

Pulsed

Pulsed current

Spot welding

Smooth tacking

Spot-Pulse

Pulsed tacking

Trigger mode

2T, 4T, Valve

Choice of trigger welding management mode.

Access to some of the welding parameters depends on the selected display mode: Settings/Display mode: Easy or Expert. Refer to the HMI ma

-

nual.

SETTINGS

• Standard

The standard DC TIG welding process allows high quality welding on most ferrous materials such as steel and stainless steel, but also copper and its

alloys including titanium. The various current and gas management possibilities allow you to perfectly control your welding operation, from priming to

the final cooling of your weld seam.

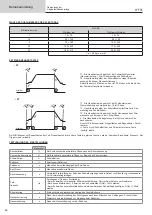

• Pulse

This pulsed current welding mode combines high current pulses (I = welding pulses) with low current pulses (cold I, workpiece cooling pulses). The

pulsed mode allows parts to be assembled while limiting temperature rises and warping. Ideal for on site use.

Example:

The welding current (I) is set to 100 A and % (cold I) = 50%, i.e. cold current = 50% x 100 A = 50.

F(Hz) is set to 10 Hz, the signal period will be 1/10 Hz = 100 ms -> a 100 A pulse every 100 ms then followed by another at 50 A.

• Spot

This welding mode allows the pre-assembly of parts before welding. Spot welding can be done manually using the trigger or timed with a predefined

spot welding period. Spot welding allows for better reproduction and non-oxidised weld points.

• Spot-Pulse

This method of welding is used to pre-assemble thin sheet metal workpieces prior to the actual welding process. Spot welding can be done manually

using the trigger or timed with a predefined spot welding period. Spot welding allows for better reproduction and non-oxidised weld points.

CHOOSING THE ELECTRODE’S DIAMETER

Electrode Ø (mm)

DC TIG

Pure tungsten

Tungsten with oxides

1

10 > 75

10 > 75

1.6

60 > 150

60 > 150

2

75 > 180

100 > 200

2.5

130 > 230

170 > 250

3.2

160 > 310

225 > 330

Approx. = 80 A per mm Ø

USING THE TRIGGER

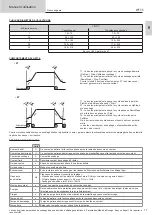

• 2T

t

t

t

t

t

t

T2

T1

Main button

T3

T1

Main button

T2

T4

T3

T1

Main button

T2

T4

>0.5s

<0.5s

<0.5s

T1 - The main button is pressed, the welding cycle starts (Pre-Gas,

I_Start, upslope and welding).

T2 - The main button is released, the welding cycle is stopped

(downslope, I_Stop, Post-Gas).

For two-button torches in T2 only, the secondary button is treated as

the main button.