28

User manual

WF 35

Translation of the original

instructions

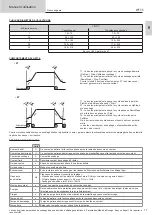

• Spot-Delay

This is a welding mode similar to Spot welding but with predefined weld and dwell times, as long as the trigger is held down. This function allows

welding very thin steel or aluminium metal sheet, limiting the risk of piercing and distortion (especially for aluminium welding).

CONFIGURING THE SETTINGS

Units

Burnback

-

Feature to help prevent the wire sticking to the bead. This is timed to coincide with the wire rising from the weld

pool.

Crater Filler

%/s

This idling current is the next phase after the current is lowered.

The intensity (% of welding current) and the time (seconds) can be programmed.

Delay

s

Time between the end of a point (excluding Post-Gas) and the start of a new point (including Pre-Gas).

Thickness

mm

The pre-installed user settings (syngergies) allow for a fully-automatic set-up. Changing the thickness setting

automatically sets the appropriate wire tension and speed.

Crater-fill feature

s

Downslope current.

Hot Start

%/s

The Hot Start is an overcurrent used at the start that prevents the wire from sticking to the workpiece. The

intensity (% of welding current) and the time (seconds) can be programmed.

Current

A

The welding current is adjusted according to the type of wire used and the material to be welded.

I Start

-

Adjustment of the ignition current.

Arc length

-

Used to adjust the distance between the end of the wire and the weld pool (tension adjustment).

Pre-Gas

s

When the torch is bled and the gas shield is created before ignition.

Tack welding

s

Set duration.

Post-Gas

s

Duration of the gas protection after the arc is extinguished. It protects the workpiece and the electrode from

oxidation.

Self-Induction Coil

-

Lessens the welding current more or less. To be set according to the welding position.

Spot welding

s

Set duration.

Voltage

V

Control over the cord’s width.

Upslope

s

Upslope current

Approach speed

-

Progressive yarn speed. Before priming, the wire moves slowly to create the first contact without jolting.

Wire speed

m/min

Amount of filler metal deposited and consequently the welding intensity and penetration.

Access to some of the welding settings depends on the selected welding process (Manual, Standard, etc.) and the selected display mode (Easy,

Expert or Advanced). Refer to the HMI manual.

GAS FLOW CONTROL

To check the gas flow rate on the manometer without unwinding the welding wire, press and hold push-button n°1 and follow the procedure on the

screen. This check should be done periodically to ensure the best possible welding. Refer to the HMI manual.

TIG (GTAW) WELDING MODE

INSTALLATION AND GUIDANCE

See power source manual.

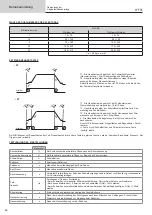

ELECTRODE SHARPENING

For optimum results, it is advised to use an electrode sharpened in the following way:

d

L

L = 3 x d for a low current.

L = d for a high current

RECOMMENDED COMBINATIONS

(mm)

Current (A)

Ø Electrode (mm)

Ø Nozzle (mm)

Argon flow rate (L/min)

0.3 - 3

3 - 75

1

6.5

6 - 7

2.4 - 6

60 - 150

1.6

8

6 - 7

4 - 8

100 - 200

2

9.5

7 - 8

6.8 - 8.8

170 - 250

2.4

11

8 - 9

9 - 12

225 - 300

3.2

12.5

9 - 10