EN

25

User manual

WF 35

Translation of the original

instructions

DESCRIPTION OF THE EQUIPMENT (II)

1-

Reel support Ø 200/300 mm

7-

Torch support

2- Wire-feed motor

8-

Interconnection cable connector

3-

Cover for coolant outlet (Blue)

9-

Gas inlet

4-

Cover for coolant inlet (Red)

10-

Power relay connector

5- Euro connector (torch)

11-

Interconnection support

6- HMI (Human Machine Interface)

12-

Transport handles

13-

Turret (pivot)

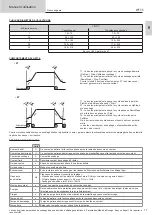

HUMAN-MACHINE INTERFACE (HMI)

HMI

Please read the Interface User Guide (HMI) which forms part of the complete product literature.

POWER SWITCH

This equipment has been designed to work exclusively with the KRONOS / NEOMIG-i range of power sources:

KRONOS 400T DUO

075337

KRONOS 400T G

075054

KRONOS 400T GW

075061

NEOMIG-i 400 G

075085

NEOMIG-i 500 G

075092

The connection between these two parts is made through a dedicated interconnection cable, available separately:

Type of torch cooling

Length

Section

Reference

Air

5m

70mm²

075443

10m

70mm²

075450

95mm²

077553

Water

1.8m

70mm²

075467

5m

70mm²

075474

10m

70mm²

075481

95mm²

075504

ATTACHING THE INTERCONNECTION CABLES

Make sure the main welding power source switched off when connecting or disconnecting the wire feeder. Ensure the machine is

unplugged from the mains, and then wait 2 minutes.

For attaching the interconnection cable between the power source and the wire feeder, refer to pages 3 or 4.

SETTING UP THE REEL

a

b

- Remove the nozzle (a) and contact tube (b) from your MIG/MAG torch.

a

b

c

- Open the wire feeder cover.

- Position the reel on its holder.

- Take into consideration the reel stands’s drive lug (c). To fit a 200 mm reel, tighten the

plastic reel holder (a) to the maximum.

- Adjust the brake wheel (b) to prevent the non-moving spool from tangling the wire when

the welding stops. Do not over tighten as this will cause the power source to overheat.