X500pro

3D printer manual

DRAFT

German

RepRap

8.3 Set Up the Second Extruder

The X500pro is equiped with two extruders. The extruders are automatically levelled by

the tool GCODE.

We recommend new users to make their first 3D printing experience with only one

extruder.

Before you start setting up the second extruder please note that you must heat up both nozzles to the

desired material specific temperature. Then you must remove the already inserted filament from the

extruder and clean up the hot end`s brass nozzle. You can for instance use a brass brush for this.

Even very small amounts of impurities could make it impossible to align both nozzles correctly. If you are

having troubles with dripping filament wait for the dripping to stop after removing the filament.

Select the right extruder by T1 command in the consol.

Traverse the print bed to the “Z = 0” and measure the distance between the first extruder and the print bed

with an appropriate tool like a dial gauge or a feeler gauge.

Use the knurled screw marked on the page to the left to transfer the height to the second extruder.

The offset in X and Y direction will be configured using Repetier-Server. Therefore Extruder 1 is used as a ref-

erence point from which the distance to the second extruder needs to be measured.

In general the offset is a machine-specific value and needs to be verified and adjusted for every machine.

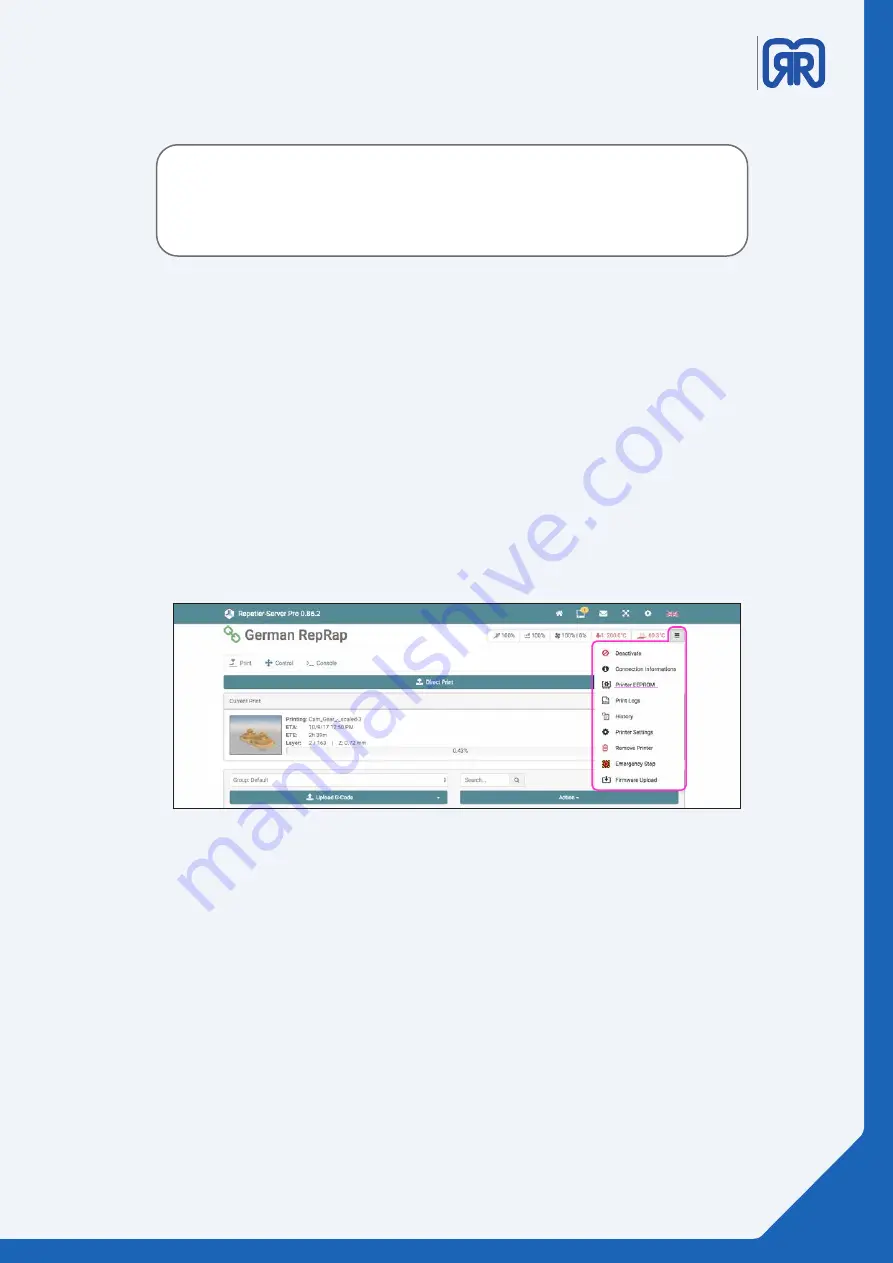

The distance will be stored in the EEPROM of the printer using Repetier-Server. Please connect to your

printer and navigate to

Printer EEPROM.

EEPROM, Repetier-Server

47/83