64

Via Leonardo da Vinci, 32/B

36034 Malo (VI) Italia

Operation and maintenance manual

Rev. 01/18-GB

TZ FIBER 540E / 630E / Conveyor-E

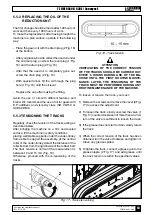

The grease contained in the hydraulic crawler is

under pressure, so do not loosen the greasing valve

(1 Fig. 17) more than a turn. If the valve is too loose,

it’s likely to be expelled under the effect of the pres-

sure of the grease, thus seriously endangering the

safety of the operator. Be careful not to loosen ever

the nipple (2 Fig. 17).

When gravel or mud are stuck between the toothed

wheel and the track links, remove them before losing.

It is abnormal if the track remains tensed after turn-

ing the valve counter-clockwise or if the track is still

loose after putting the grease into the nipple. In any

case, avoid removing the tracks or disassembling

the track tensioner cylinder because the pressure

of the grease inside the track tensioner cylinder is

very dangerous.

5.5.4 DISASSEMBLYING THE TRACKS

The tracks used in the «TZ FIBER» excavator have

a structure with steel core and rubber coating (Fig.

19). The sculptures are used to provide stability

when driving on soft ground.

These are located at the bottom resting on the

ground, while the guides of the wheel located inside

the track prevent the track to get out of the guide

rollers.

Improper use of the machine and use the machine

on stony and uneven surfaces lead to a premature

wear and tear of the tracks.

Should it be necessary to replace the tracks, pro-

ceed as follows.

After bringing the machine on a firm and leveled

surface, lift the machine in safety conditions placing

well stable supports under the under-trolley frame

able to support the assembly.

1) Remove the screws and the lid (3 Fig. 17) to

access the adjustment.

2) To loosen the track, slowly unscrew the valve (1

Fig. 17) counterclockwise not more than a turn. A

turn of the valve is sufficient to loosen the track.

The grease contained in the hydraulic cylinder is

under pressure, thus avoid loosen the greasing

valve (1 Fig. 17) for more than a turn. If the valve

is loosened too much, there is the risk of being

expelled under the effect of grease pressure,

seriously endangering the safety of the operator.

Be careful not to loosen the nipple (2 Fig. 17).

If gravel or mud are stuck between the toothed

wheel and the track links, remove them before

losing.

4) If the grease does not start to drain, slowly rotate

the track.

5) Place three steel tubes (4 Fig. 18) within the track

in the space between the rollers. Rotate the driv-

ing wheel in reverse (5 Fig. 18) so that the steel

pipes proceed with the track and place between

the tensioning wheel and it. Do strength side (6

Fig. 18) to slide the track and release it from the

track tensioning wheel.

5.5.5 ASSEMBLYING THE TRACKS

Also for the installation of the track, it is necessary

to bring the machine on a solid and flat surface, thus

lift the machine safely putting very stable supports

under the under-trolley frame able to support the

assembly and proceed with the assembly opera-

tions of the track.

1) Check that the grease contained in the hydraulic

cylinder is removed.

Fig. 20 - Dismantling track

Fig. 19 - Structure track

ROPES

STEEL

STEEL CORE

SCULPTURE

WHEEL SIDE

GEAR WHEEL

HOLE