63

TZ FIBER 540E / 630E / Conveyor-E

Via Leonardo da Vinci, 32/B

36034 Malo (VI) Italia

Operation and maintenance manual

Rev. 01/18-GB

Fig. 18 - Track tension

3

Fig. 17 - Tracks tensioning

5.5.2 REPLACING THE OIL OF THE

REDUCTION UNIT

The first change should be made after 100 hours of

work and then every 1000 hours of work.

To make the replacement, after having brought the

machine in a plan surface, operate in the following

way:

- Place the gear unit with the drain plug (2 Fig. 16)

at the bottom.

- After you place a bowl to collect the used oil under

the oil drain plug, unscrew the level plug (1 Fig.

16) and the drain plug (2 Fig. 16).

- After that the used oil is completely gone out,

screw the drain plug (2 Fig. 16).

- With special funnel, fill the oil through the plug

hole (1 Fig. 16) until the oil level.

- Replace the cap after making the filling.

Avoid the use of oils with different features and

brand. We recommend the use of oil for gears with

E.P. additives and viscosity class ISO VG150 or

SAE 80W/90.

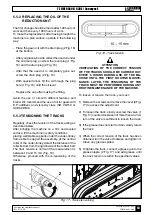

5.5.3 TENSIONING THE TRACKS

Regularly check the tension of the tracks acting as

described below.

After bringing the machine on a firm and leveled

surface, lift the machine in safety conditions

placing well stable supports under the under-trolley

frame able to support the assembly. At the central

roller of the under-trolley, detect the distance of the

roller bottom from the rigid inside of the rubber belt.

The track tension is normal if the measurement is

between 10 and 15 mm (Fig. 18).

Otherwise, proceed with the re-tensioning of the

tracks.

ATTENTION

VERIFICATION OF THE CORRECT TENSION

OF THE TRACKS SHOULD BE CARRIED OUT

EVERY 8 HOURS DURING USE OF THE MA-

CHINE UNTIL THE FIRST ROUTINE MAINTE-

NANCE. LATER, THE TENSIONING OF THE

TRACK MUST BE PERFORMED DURING ANY

ROUTINE MAINTENANCE OF THE MACHINE.

To loosen or tension the track, you must:

1) Remove the screws and remove the cover (3 Fig.

17) to access the adjustment.

2) To loosen the track, slowly unscrew the valve (1

Fig. 17) counterclockwise not more than a turn. A

turn of the valve is sufficient to loosen the track.

3) If the grease does not start to drain, slowly rotate

the track.

4) When the correct tension of the track has been

obtained, turn the valve clockwise and tighten it.

Clean any grease spilled.

5) To tighten the track, connect a grease gun to the

grease nipple (2 Fig. 17) and add grease until

the track tension is within the specified values.