60

Via Leonardo da Vinci, 32/B

36034 Malo (VI) Italia

Operation and maintenance manual

Rev. 01/18-GB

TZ FIBER 540E / 630E / Conveyor-E

cartridge every 8 hours of work.

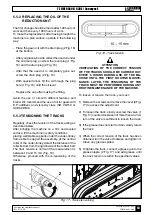

To clean the filter, you need to:

- Remove the right side guard which protects the

motor, unscrewing the three knobs that fix it to

the frame.

- Using the three snap springs (13 Fig. 10), unhook

the cover from its seat.

- Remove the filtering cartridges and carefully clean

them. Carry out the cleaning using a jet of air with

a pressure not higher than 3 bar, directing the air

jet along the entire inner surface of the filtering

cartridge until the complete removal of the present

dust. It should be noted that dust and debris are

deposited on the outer surface of the cartridge.

Then check the complete removal of dirt.

- If necessary, clean the vacuum air discharge

valve (4 Fig. 10).

The cartridge must be replaced if it is so dirty

that it can not be cleaned. Furthermore, if the

cartridge is damaged or broken at any point, it

must be replaced. Normally, however, it is bet-

ter to replace it every 50 hours of use.

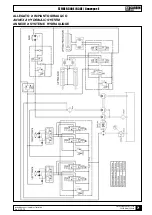

5.2.2 COOLING CIRCUIT

The machine is equipped with a two-stage com-

bined heat exchanger; a circuit intended for engine

water and the other to the hydraulic oil exchanger.

The hydraulic fluid level is visible in the tank level

indicator, while the engine water level is visible

through the lateral slot (28 Fig. 1/B).

To add water to the radiator, you must remove the

screws that secure the cover (27 Fig. 1/B). Un-

screw the cap and fill the radiator.

5.2.3 AFTER THE FIRST 8 HOURS

During the initial period of the machine’s lifetime,

it will undergo a general adjustment of the various

mechanical parts, it is therefore essential to carry

out checks on the machine with the highest accu-

racy. Each new machine then, must be checked

after the first 8 hours of operation, taking care to

verify:

- the tightness of all nuts and bolts;

- the correct oil level in the hydraulic oil tank;

- absence of leakage of oil from the hydraulic

components;

- correct lubrication of components where there is

motion or rotation;

- that the parts match the requirements estab-

lished by the Manufacturing company. Only use

original spare parts.

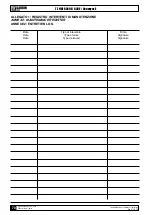

5.3 ROUTINE MAINTENANCE

OPERATIONS

EVERY 8 HOURS OF WORK:

- Check the proper tightness of all fasteners. In

particular, check the tightening of the screws of

the slides.

- Check the state of wear of the tools and, if worn

Fig. 12 - Peaks / slides distance

cm 1-1,5

Fig. 13 - Welding sections