49

PB

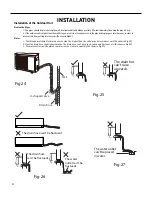

INSTALLATION

Installation Dimension Diagram

Space to the ceiling

Space to the wall

At least 5 inches(”)

At least 78

inches(”)

At least 4 inches(”)

At least 4 inches(”)

Space to the wall

Space to the obstruction

ro

olf

eht

ot

e

ca

p

S

At least 60 inches(”)

Space to the obstructio

At least 28 inches(”)

At least

Space to the wall

12 inches(”)

At least 24 inches(”)

Space to the obstruction

At least 12 inches(”)

Drainage pipe

Space to the obstruction

At least 24 inches(”)

Space to the obstruction

Summary of Contents for FSHW091

Page 8: ...8 INTRODUCTION FSHSW09A1A FSHSW12A1A Figure 102 Indoor Units FSHSW18A3A FSHSW24A3A FSHSW36A3A ...

Page 47: ...47 INSTALLATION ...

Page 48: ...48 INSTALLATION Installation Tools ...

Page 72: ...72 WIRED CONTROLLER Display ...

Page 122: ...122 TROUBLESHOOTING Malfunction of IDUFanMotorU8 Service Manual No Start End ...

Page 146: ...146 WIRING DIAGRAMS Figure 8054 9 12KOutdoorUnitWiringDiagrams 60000706067401 3 2 N 1 C3 C4 ...

Page 158: ...158 FIgure 906 PARTS CATALOG 9KOutdoorUnit 28 27 29 31 30 32 ...

Page 160: ...160 PARTS CATALOG 12k OutdoorUnit 28 27 29 31 30 32 FIgure 907 ...