5-20

C

OMMISSIONING

THE

ALINTE

4

PAGE

S

YSTEM

poor mechanical/vacuum conformance

gum on plate increases dot% by

3%

–

4%

poor processor conditions for:

A

)

pre-heat

B

)

developer pH reading should be

12

±

0.25

(11.75 to 12.25)

C

)

process time

D

)

developer scrub pressure.

Consult FFEI Customer Support to resolve a non-uniformity fault.

5.3.5.3 Test Image Quality

1.

Expose an S&T image from the PCI Diagnostics menu (Stock Images

folder) at the fixed resolution of 96 and test the image quality for:

screen quality

raster quality

vignette quality

dot prediction accuracy

highlight dot quality.

2.

If any issues are detected then refer to the

Service Guide

.

3.

If the issue cannot be resolved then contact the FFEI Customer

Support (UK).

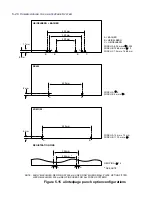

5.3.6 Check Edge Detect Function

See the

Service Guide

for details on the full Edge Detect setup.

Check the plate edge detect function as follows:

1.

Enter the commands:

diagnostics/service/traverse> halt

diagnostics/service/traverse> medirq

Check that the Edge Detect PCB laser beam is ON.

2.

Load a plate into the drum and move the traverse by hand so that the

edge detect beam moves across the plate edge.

Summary of Contents for alinte4page

Page 1: ......

Page 12: ...PRELIMINARIES...

Page 29: ...ALINTE4PAGE INSTALLATION GUIDE 2 7 Figure 2 5 Autofeeder elevator warning label...

Page 40: ...2 18 SAFETY ON THE ALINTE4PAGE Figure 2 13 Location of interlock covers alinte4page SAL 2 1...

Page 48: ...2 26 SAFETY ON THE ALINTE4PAGE...

Page 56: ...3 8 UNPACKING AND HANDLING...

Page 98: ...4 42 INSTALLING ALINTE4PAGE EQUIPMENT AND SOFTWARE Figure 4 32 Removing transit fixing view 2...