Maintenance 5. Actuator Units

N6 Rev.2

287

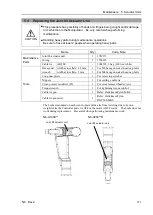

5.3.1 Joint #3 (N6-A1000**)

Removal

Joint #3

Actuator Unit

N6-A1000**

(1) Remove the covers.

Arm #4 side cover (2 covers), Joint #4 inside cover, Joint #4 outside cover

Joint #4 side cover (2 covers), Arm #3 cover, Arm #3 inside cover

Arm #2 cover (2 covers)

For details, refer to

Maintenance 3. Covers.

(2) Remove the cable unit from Joint #1 to Joint #3.

For details, refer to the Removal steps (2) through (5), (9) through (25), (27),

(29), and (33) in

Maintenance 4.1 Cable Unit (N6-A1000*): Cable direction

Standard (backward).

(3)

Disconnect the connector connected to the

encoder board 2.

Connector:

EB0x_CN2 (Joint #3 side)

Be careful that the jumper pins on the board

do not come off.

(4)

Remove the Joint #3 actuator unit and the

O-ring.

Hexagon socket head cap bolts:

8-M6

×

35 (with plain washer)

Be sure to have at least 2 people to perform

the operation since the parts being heavy.

When you remove it, be careful not to catch

the cables on the Joint #3 actuator unit.

Joint #3 actuator unit

8-M6

×

35 (with plain washer)

NOTE

NOTE

Summary of Contents for N6 Series

Page 1: ...Rev 2 EM187R3735F 6 Axis Robots N6 series MANIPULATOR MANUAL ...

Page 2: ...Manipulator manual N6 series Rev 2 ...

Page 8: ...vi N6 Rev 2 ...

Page 14: ......

Page 27: ...Setup Operation 1 Safety N6 Rev 2 15 N6 A850 R C A D F G F E H G F B G F G F F F N6 A850 BR F ...

Page 34: ...Setup Operation 2 Specifications 22 N6 Rev 2 N6 A850 BR Cable direction Upward ...

Page 52: ...Setup Operation 3 Environment and Installation 40 N6 Rev 2 N6 A850 R Maximum motion range 802 ...

Page 66: ...Setup Operation 4 End Effectors 54 N6 Rev 2 N6 A850 R Unit mm ...

Page 104: ......

Page 274: ...Maintenance 4 Cable 262 N6 Rev 2 4 7 1 Signal Power cable ...

Page 275: ...Maintenance 4 Cable N6 Rev 2 263 ...

Page 276: ...Maintenance 4 Cable 264 N6 Rev 2 4 7 2 User Cable ...