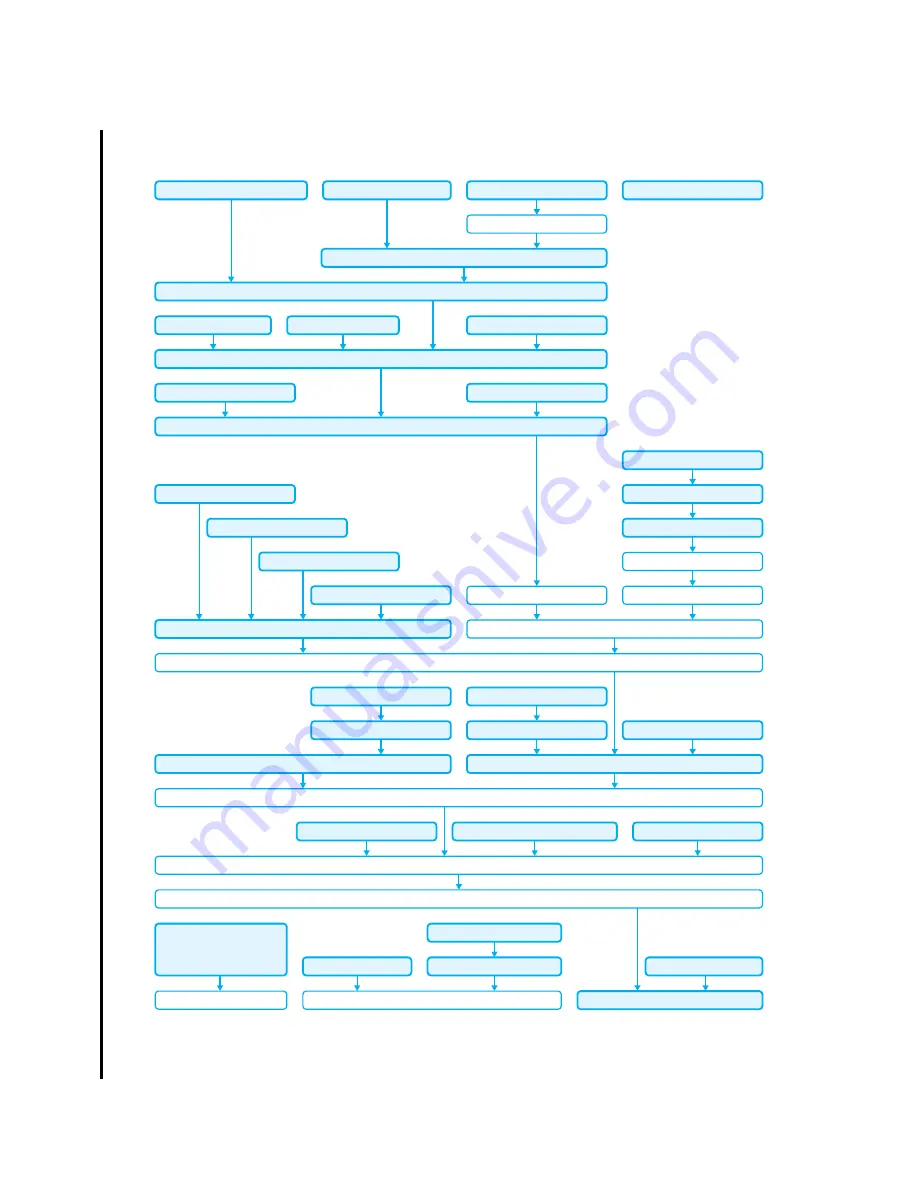

Chapter 3 Removal and Replacement Procedures (RRPs)

Version 3 2008.06.13

COVER WINDOW TNR (Replacement 49)

COVER REAR (Replacement 43)

COVER SIDE R LOW (Replacement 41)

COVER SIDE L LOW (Replacement 40)

PWBA LVPS (Replacement 35)

DUCT FAN ASSY (Replacement 34)

COVER POLE OUT (Replacement 45)

COVER REAR (Replacement 43)

COVER TOP (Replacement 42)

CHASSIS ASSY LVPS (Replacement 32)

KIT DRIVE ASSY PH (Replacement 28)

SWITCH (Replacement 39)

HARN ASSY INTERLOCK (Replacement 33)

KIT PWBA MCU (Replacement 29)

BREAKER GFI (Replacement 30)

HARN ASSY SW PWR (Replacement 31)

HARN ASSY INTERLOCK (Replacement 33)

KIT BLOCK PHD LEFT (Replacement 25)

DRIVE ASSY SUB (Replacement 26)

KIT FEED ROLL/SOL/CLUTCH (Replacement 24)

MEMORY CARD (Replacement 60)

KIT DRIVE ASSY MAIN (Replacement 27)

COVER ASSY ESS (Replacement 44)

COVER REAR (Replacement 43)

SHIELD ASSY ESS (Replacement 38)

PWBA FAX (Replacement 37)

KIT ESS PWBA (Replacement 36)

LED ASSY ERASE (Replacement 48)

KIT BLOCK PHD RIGHT (Replacement 47)

KIT ROLL ASSY FEED (Replacement 56)

SENSOR PHOTO: SSI NO PAPER (Replacement 55)

ACTUATOR SSI (Replacement 54)

COVER POLE OUT (Replacement 45)

COVER ASSY ESS (Replacement 44)

FUSER ASSY (Replacement 51)

COVER ASSY SIDE L (Replacement 46)

COVER ASSY SIDE R (Replacement 50)

COVER ASSY SIDE L (Replacement 46)

PHD Unit (Replacement 57)

Closing COVER ASSY FRONT

Separator Roller (Replacement 58)

Tray 1 (Replacement 59)

CONSOLE ASSY PANEL (Replacement 52)

Closing COVER ASSY FRONT

Closing COVER WINDOW TNR

Toner Cartridge (K), (C), (M), (Y)

(Replacement 53)

PHD Unit (Replacement 57)

FUSER ASSY (Replacement 51)

Replacement FLOW

(Replacement 24~60)

Summary of Contents for 2135CN

Page 1: ...Dell 2135cn Service Manual 09 Oct 2009 ...

Page 13: ...viii Version 1 2008 02 01 4 6 2 Caution label for toner cartridges Mnt00006KA ...

Page 14: ...ix Version 1 2008 02 01 Wsb00007KA ...

Page 15: ...x Version 1 2008 02 01 4 6 3 Caution label for SSI and tray Mnt00008KA ...

Page 16: ...xi Version 1 2008 02 01 4 6 4 Caution label for ROS Mnt00009KA ...

Page 17: ...xii Version 1 2008 02 01 4 6 5 Caution label for transfer belt and PHD unit Mnt00010KA ...

Page 19: ...xiv Version 3 2008 06 13 Mnt00012KB ...

Page 197: ...1 169 Chapter 1 Troubleshooting Version 2 2008 03 31 Flows 95 Solid black ...

Page 217: ...1 189 Chapter 1 Troubleshooting Version 3 2008 06 13 Flows 103 Grey Background Mnt01115KA ...

Page 219: ...1 191 Chapter 1 Troubleshooting Version 2 2008 03 31 Flows 104 Skew Mnt01116KA ...

Page 222: ...1 194 Chapter 1 Troubleshooting Version 2 2008 03 31 Flows 105 Paper damage Mnt01117KA ...

Page 382: ...1 354 Chapter 1 Troubleshooting Version 1 2008 02 01 Wsb02025KA ...

Page 388: ...1 360 Chapter 1 Troubleshooting Version 1 2008 02 01 Chart Parallelism Perpendicularity ...

Page 480: ...2 21 Chapter 2 Operation of Diag Version 3 2008 06 13 0 12 0 3 4 0 1 004 0 12 524 3 6 7 ...

Page 763: ...Chapter 5 Parts List Chapter 5 Parts List CONTENTS Version 1 2008 02 01 ...

Page 787: ...5 24 Chapter 5 Parts List Version 3 2008 06 13 PL10 5 Frame With Scanner Assy Illustration ...

Page 795: ...5 32 Chapter 5 Parts List Version 3 2008 06 13 PL10 9 Scanner Assy 1 2 Illustration ...

Page 811: ...6 12 Chapter 6 Principle of Operation Fax Version 1 2008 02 01 Blank Page ...

Page 824: ...6 25 Chapter 6 Principle of Operation Scanner Version 1 2008 02 01 Blank Page ...