Chapter 2

2-32

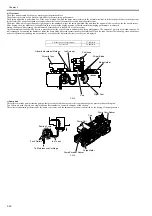

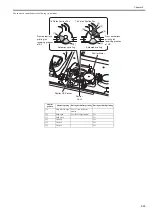

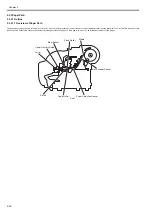

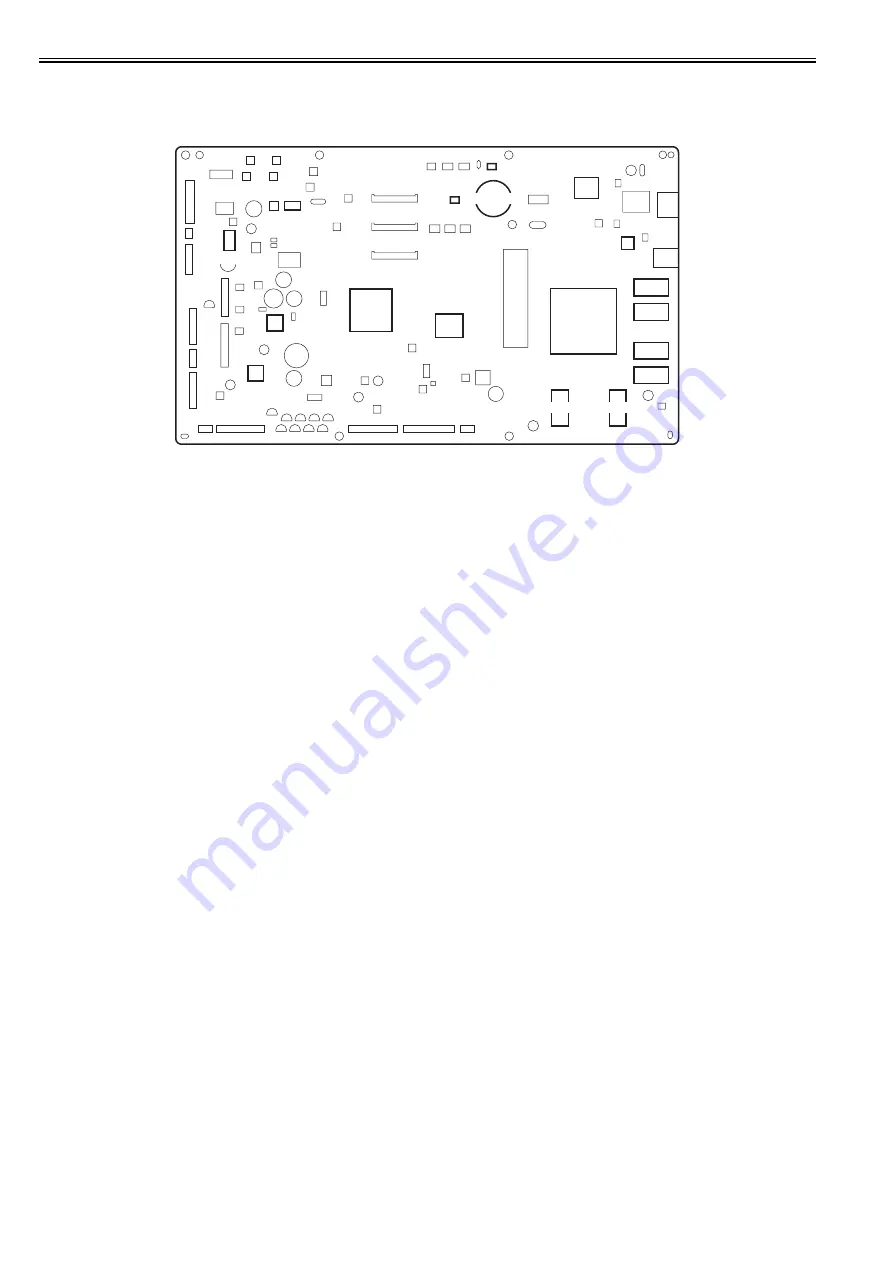

2.4.2 Main Controller

2.4.2.1 Main controller PCB components

0031-2542

F-2-29

a) ASIC (IC1/IC2)

The ASIC (IC1/IC2) with a 32/16-bit internal bus is driven in sync with the 165/66 MHz external clock. It supports the following functions:

Image processing unit

This unit converts the RGB multi-value image data or CMYK multi-value data received from the host computer through the interface connector to the binary image

data for the ink colors used.

DMA controller

This controller control DMA transfer of the data transferred through the input interfaces as well as DMA transfer of the data stored in the DIMM.

Image data generation/output function

This function generates image data for color printing from the received image data and the mask pattern (corresponding to print mode) stored in the FLASH ROM,

and stored the generated image data in DIMM. It also outputs the generated image data to the carriage PCB.

Interrupt controller

This controller receives and processes internal interrupts and external interrupts from the USB, image processing unit, and expansion card slot.

Timer function

Even when the printer is turned off, the timer function is held on using the RTC(IC803) and lithium battery(BATS801) to assist the cleaning function.

When the power cord is plugged to the outlet, power is supplied to the RTC and therefore the lithium battery power is not consumed.

Heat Enable signal control function

This function uses the pulse width to perform variable control of the time of application of the Heat Enable signal to the nozzle heater board for each printhead

nozzle array.

Linear scale count function

This function reads the linear scale when the carriage moves, thus generating the ink discharge timing. It also counts the linear scale timing cycle using the reference

clock to measure the carriage moving speed.

Dot count function

This function controls the discharge dots used as the information for Heat Enable signal control, maintenance jet control, cleaning control, and remaining ink level

for each nozzle array.

Operation panel control function

This function controls serial communication with the operation panel.

PWM control function

This function controls driving of the suction fan and mist fan as well as the temperature of the printhead.

Remaining ink level detection function

This function detects the remaining level of each color of ink based on the signal received from the hollow needle mounted in the ink tank unit.

LED control function

This function controls the LEDs on the ink tank unit.

I/O port function

This function controls input signals from sensors.

Power ON/OFF control function

This function controls turning on/off of the drive power (26 V and 21.5 V) supplied from the power supply PCB.

Head DI sensor read control function

This function controls read operation by the head DI sensor.

Multi sensor control function

This function controls the LED, adjusts the gain, and controls obtainment of the reading for the multi sensor.

EEPROM control function

This function controls the EEPROMs of individual ink tanks, the maintenance cartridge EEPROM, the EEPROM on the maintenance cartridge relay PCB, and the

IC4200

IC4300

IC4401

IC2

IC1

IC301

IC302

IC601

IC602

IC603

IC604

IC803

IC802

IC701

IC2501

IC4101

BATS801

Summary of Contents for image Prograf iPF780 Series

Page 1: ...Mar 27 2014 Service Manual iPF780 760 750 series iPF785...

Page 9: ...Chapter 1 PRODUCT DESCRIPTION...

Page 57: ...Chapter 2 TECHNICAL REFERENCE...

Page 117: ...Chapter 3 INSTALLATION...

Page 125: ...Chapter 4 DISASSEMBLY REASSEMBLY...

Page 175: ...Chapter 4 4 49 2 Shaft Cleaner 1 F 4 97 1 1...

Page 176: ...Chapter 4 4 50 3 Upper Cover Hinge Catch 1 Roll Cover Slide Guide 2 F 4 98 2 1...

Page 179: ...Chapter 5 MAINTENANCE...

Page 186: ...Chapter 6 TROUBLESHOOTING...

Page 212: ...Chapter 7 SERVICE MODE...

Page 267: ...Mar 19 2014 PARTS CATALOG iPF786 785 781 780 765 760 755 750...

Page 301: ...2 25 FIGURE 10 PLATEN GUIDE UNIT 1 3 6 2 8 4 5 10 10 10 9 9 11...

Page 326: ......