Chapter 2

2-14

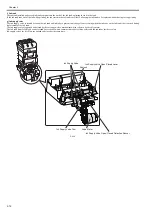

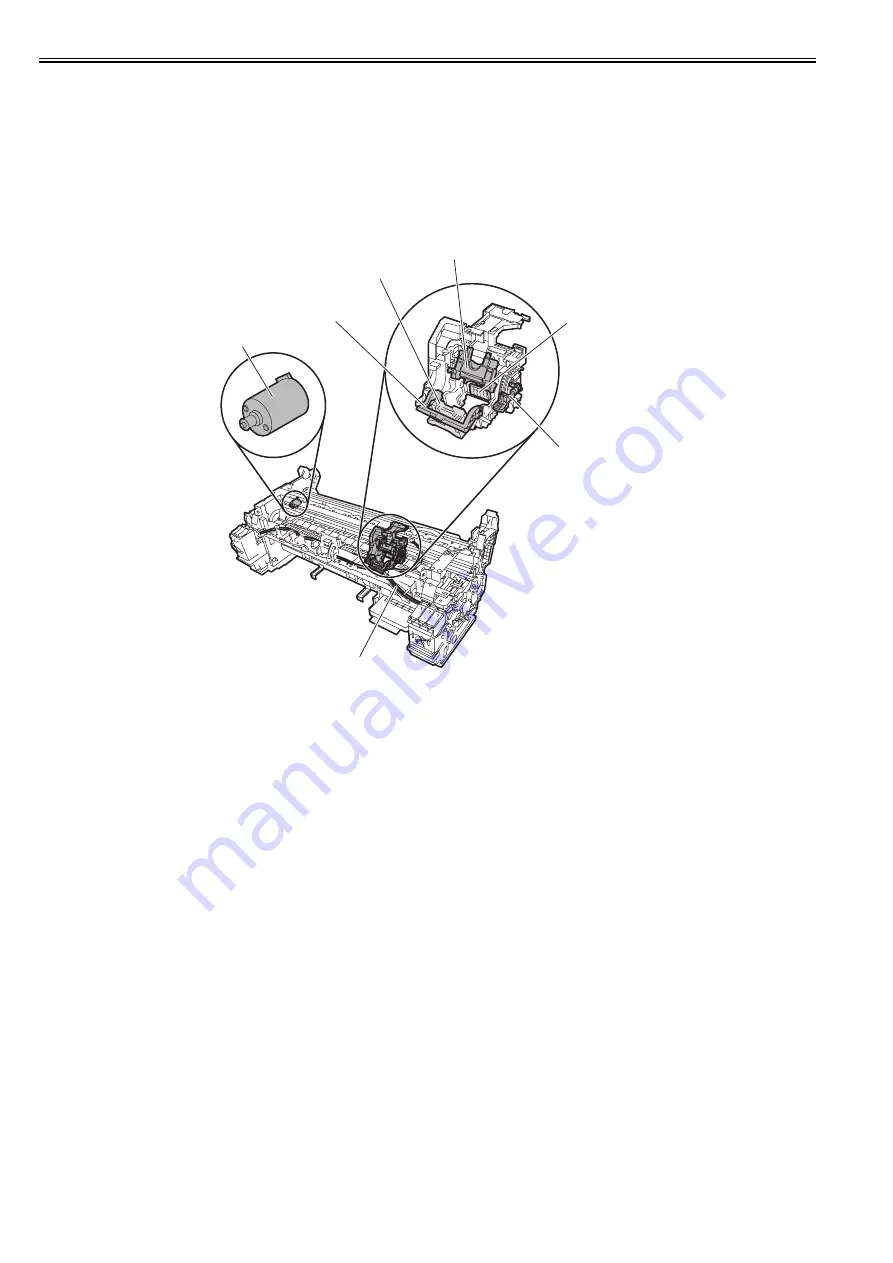

2.3.2.3.2 Structure of Carriage Unit

0023-2472

a) Printhead mounting unit

The printhead is secured to the carriage by the printhead fixer lever.

When the printhead is secured to the carriage, the signal contact of the carriage PCB touches the signal contact point of the printhead, allowing print signals to be

transmitted.

The ink passage from the ink tank is connected to the printhead through the ink tube and joint.

b) Ink port

Ink is supplied to the printhead via an ink tube, which is connected to ink joints, and runs between the tube guides to reach the carriage and follow its movement.

F-2-11

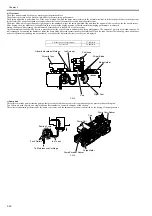

c) Control unit

The carriage PCB is connected to the main controller PCB with a flexible cable. The flexible cable moves in conjunction with the carriage.

A photo-coupler-type encoder is mounted at the top of the rear of the carriage to detect the slit on the linear scale during carriage movement, thus controlling the

print timing.

d) Carriage drive

Mechanical misregistrations in the vertical/horizontal and bidirectional print positions of the printhead mounted can be corrected by selecting Adjust Printer from

the main menu to shift the print timing.

A DC-operated carriage motor drives the carriage reciprocally on the platen by way of the carriage belt.

The carriage home position, or the capping position, is detected by the sensor flag on the right side of the carriage and the photointerrupter-based carriage HP sensor

on the right side of the printer. When the linear scale position is set as a reference home position for use in subsequent position control operations, the carriage motor

is driven by a control signal generated from the main controller PCB.

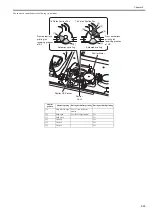

e) Printhead maintenance unit

This printer cleans the printhead with the carriage halted at its home position.

Wiping takes place through the rotation of the motor.

Wiper blades mounted on the carriage wipe the printhead while the carriage is halted at its home position.

Wet wiping is carried out for added wiping removal performance, whereby the wiper blades are moistened with glycerin as they are pressed against an absorber

impregnated with glycerin.

Maintenance jet ejection is carried out on the cap, at the maintenance jet tray.

A suction operation is carried out by a suction cap in the purge unit.

Slant Adjustment Lever

Carriage Motor

Ink Tube

Joint for Ink Supply

Printhead Fixer Cover

Printhead Fixer Lever

Terminal

Summary of Contents for image Prograf iPF780 Series

Page 1: ...Mar 27 2014 Service Manual iPF780 760 750 series iPF785...

Page 9: ...Chapter 1 PRODUCT DESCRIPTION...

Page 57: ...Chapter 2 TECHNICAL REFERENCE...

Page 117: ...Chapter 3 INSTALLATION...

Page 125: ...Chapter 4 DISASSEMBLY REASSEMBLY...

Page 175: ...Chapter 4 4 49 2 Shaft Cleaner 1 F 4 97 1 1...

Page 176: ...Chapter 4 4 50 3 Upper Cover Hinge Catch 1 Roll Cover Slide Guide 2 F 4 98 2 1...

Page 179: ...Chapter 5 MAINTENANCE...

Page 186: ...Chapter 6 TROUBLESHOOTING...

Page 212: ...Chapter 7 SERVICE MODE...

Page 267: ...Mar 19 2014 PARTS CATALOG iPF786 785 781 780 765 760 755 750...

Page 301: ...2 25 FIGURE 10 PLATEN GUIDE UNIT 1 3 6 2 8 4 5 10 10 10 9 9 11...

Page 326: ......