119

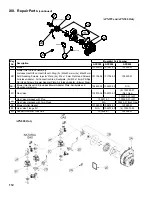

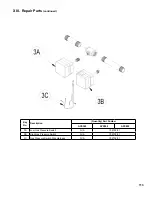

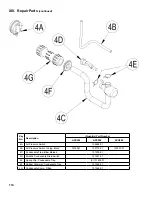

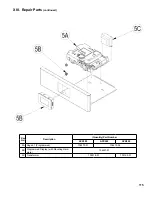

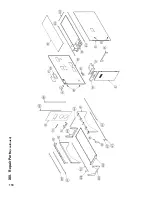

Xiii. repair Parts

(continued)

Key

no. Description

(Quantity) Part number

aPX399

aPX500

aPX800

6A

Jacket, Rear/Bottom Panel

103406-02

103407-01

N/A

6B

Jacket, Left Side Panel

102776-06

102776-07

103232-01

6C

Jacket, Right Side Panel

102776-02

102610-01

103233-01

6D

Partition Shelf Assembly

102831-06

102831-07

103237-01

6E

Jacket, Top Panel

101218-06

101218-07

103234-01

6F

Heat Exchanger Support Assembly, Right Side

101232-06

101232-07

103228-01

6G

Heat Exchanger Support, Left Side

101224-06

101224-07

103227-01

6H

Bracket, High Voltage Terminal

102780-01

6J

Bracket, Rear HX Support

101381-01

6K

Jacket Support Bracket

(2) 101593-01

(1) 101593-01

N/A

6L

Lower Front Door Assembly

101227-02

101227-01

6M

Jacket, Upper Front Panel

101509-01

6N

Bracket, Right Clip

101508-01

6P

Rubber Pad, Right Clip

101245-01

6R

Draw Latch

101037-01

6S

Bracket, Left Clip

101507-02

N/A

Bracket, HX Strap

N/A

103229-01

6T

Access Panel (5’ x 16’)

N/A

102612-01

N/A

6U

Gasket, Access Panel (5’ x 16’)

N/A

102613-01

N/A

6V

Bracket, Gas Train

N/A

102611-01

103240-01

6W

Gasket, Access Panel (5’ x 8’)

(1) 102877-01

(2) 102877-01

(6) 102877-01

6X

Jacket, Rear Panel

N/A

103230-01

6Y

Access Panel (5’ x 8’)

(1) 102873-01

(2) 102873-01

(6) 102873-01

6Z

Control, Slid Tray

102777-01

103336-01

6AA

Gasket, Rear to Base & Partition

N/A

103241-01

6BB

Gasket, Rear to Side

N/A

103242-01

6CC Gasket, Side to Base & Partition

N/A

103243-01

6DD Gasket, Side to Base Support

N/A

103244-01

6EE Gasket, Side to Header Strap

N/A

103245-01

6FF Gasket, Side to HX Support

N/A

103246-01

6GG

Heat Exchanger Support, Front/Rear

N/A

103231-01

6HH Base Pan

N/A

103226-01

6JJ

Bracket, Partition Shelf Support

N/A

103239-01

Nylon Glide

(4) 8186006

(6) 8186006

Summary of Contents for Apex APX399

Page 65: ...65 VIII Electrical continued Figure 43 Ladder Diagram ...

Page 66: ...66 VIII Electrical continued ...

Page 67: ...67 Figure 44 Wiring Connections Diagram VIII Electrical continued ...

Page 110: ...110 1P 3 1P 2 1P 1 XIII Repair Parts continued 1C 1D 1E ...

Page 116: ...116 XIII Repair Parts continued ...

Page 118: ...118 XIII Repair Parts continued ...

Page 129: ...129 SERVICE RECORD DATE SERVICE PERFORMED ...

Page 130: ...130 SERVICE RECORD DATE SERVICE PERFORMED ...