26

iV. Venting

B. CPVC/PVC Venting (continued)

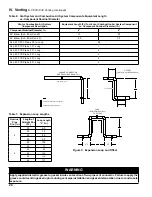

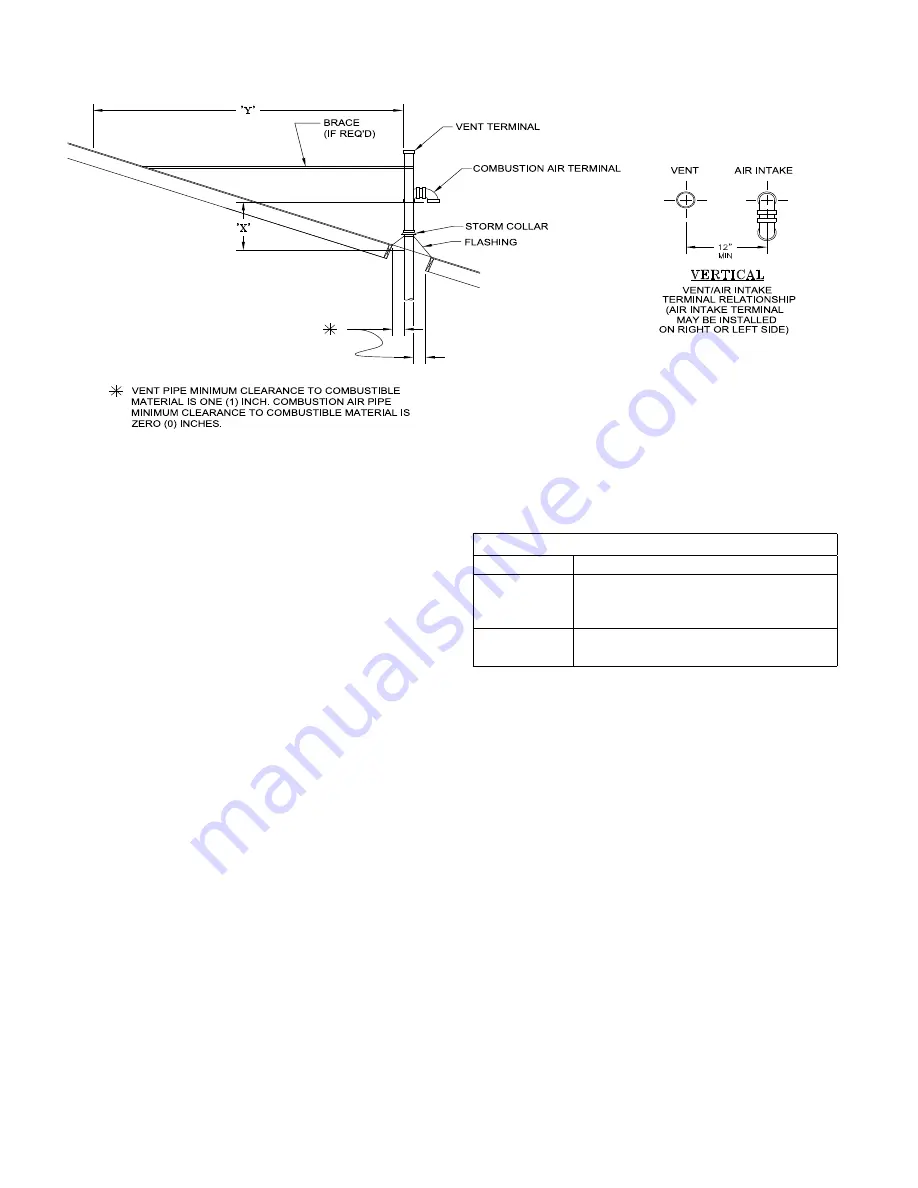

Extend vent/combustion air piping to maintain minimum vertical (‘X’) and minimum horizontal (‘Y’) distance of

twelve (12) inches (18 inches Canada) from roof surface. allow additional vertical (‘X’) distance for expected

snow accumulation.

Figure 13: Direct Vent - Vertical Terminations

with Sloped roof

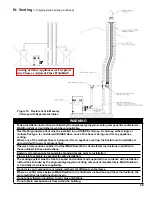

• Size roof opening to allow easy insertion

of combustion air piping and allow proper

installation of flashing and storm collar

to prevent moisture from entering the

structure.

-

Use appropriately designed vent flashing

when passing through roofs. Follow

flashing manufacturers’ instructions for

installation procedures.

- Extend combustion air pipe to maintain

minimum vertical and horizontal distance

of twelve (12) inches from roof surface.

Allow additional vertical distance for

expected snow accumulation. Provide

brace as required.

- Install storm collar on combustion

air pipe immediately above flashing.

Apply Dow Corning Silastic 732

RTV Sealant between combustion

air pipe and storm collar to provide

weather-tight seal.

• Install Rodent Screen and Combustion

Air Terminal (supplied with boiler), see

Figure 10 for appropriate configuration.

• Brace exterior piping if required.

C.

Polypropylene Venting

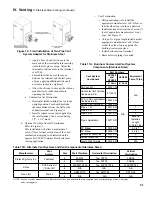

Apex boilers have been approved for use with

polypropylene vent system.

It is an installing contractor responsibility to

procure listed below polypropylene vent system pipe

and related components.

Polypropylene vent system manufactures are listed

below:

approved Polypropylene Vent System Manufacturers

Make

Model

M&G/DuraVent

PolyPro Single Wall

Rigid Vent

PolyPro Flex

Flexible Vent (APX399 and

APX500)

Centrotherm

Eco Systems

innoFlue SW

Rigid Vent

Flex

Flexible Vent (APX399 and APX500)

NOTE: Do not mix vent components from approved

manufacturers.

M&G/DuraVent PolyPro Single Wall Rigid Vent

and PolyPro Flex Flexible Vent comply with the

requirements of ULC-S636-08 ‘Standard for Type BH

Gas Venting Systems’.

Centrotherm Eco Systems InnoFlue SW Rigid Vent

and Flex Flexible Vent comply with the requirements

of UL 1738 ‘Standard for Safety for Venting Systems’

and ULC-S636-08 ‘Standard for Type BH Gas Venting

Systems’.

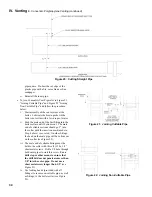

For polypropylene vent system installation details refer

to an approved manufacturer either Rigid Single Wall

Polypropylene Vent Installation Instructions, or Flexible

Polypropylene Vent Installation Instructions provided

with a manufacturer specific kits. See Tables 9 and 10.

Refer to Table 8 ‘Vent/Combustion Air Pipe Length –

Two-Pipe Direct Vent System Options’ for minimum

and maximum listed equivalent length values.

All terminations must comply with listed options for

two-pipe venting system. See Figures 8 thru 12 for

details.

Summary of Contents for Apex APX399

Page 65: ...65 VIII Electrical continued Figure 43 Ladder Diagram ...

Page 66: ...66 VIII Electrical continued ...

Page 67: ...67 Figure 44 Wiring Connections Diagram VIII Electrical continued ...

Page 110: ...110 1P 3 1P 2 1P 1 XIII Repair Parts continued 1C 1D 1E ...

Page 116: ...116 XIII Repair Parts continued ...

Page 118: ...118 XIII Repair Parts continued ...

Page 129: ...129 SERVICE RECORD DATE SERVICE PERFORMED ...

Page 130: ...130 SERVICE RECORD DATE SERVICE PERFORMED ...