27

iV. Venting

C. Polypropylene Venting (continued)

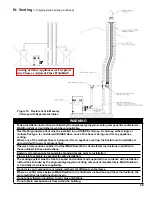

When using flexible polypropylene vent pipe (liner):

• Flexible pipe must be treated carefully and stored at

temperatures higher than 41°F (5°C).

• Do not bend or attempt to install flexible pipe if

it has been stored at lower ambient temperature

without allowing the pipe to warm up to a higher

temperature first.

CaUTiOn

Bending or attempting to install flexible pipe if it

has been stored at ambient temperature below

41°F (5°C) will cause material to become brittle

and lead to cracks.

When flexible polypropylene pipe (liner) is

used

for combustion product venting, it must

not be installed at an angle greater than 45

degrees from vertical plane.

This will insure

proper condensate flow back towards the boiler.

CaUTiOn

Do not install flexible polypropylene pipe at an

angle greater than 45 degrees from vertical plane

when used for combustion product venting.

Failure to do so will result in improper condensate

drainage towards the boiler and possible

subsequent vent pipe blockage.

• When flexible polypropylene pipe (liner) is used

for

combustion air supply

to a boiler, the pipe

(liner) can be installed in vertical or horizontal

position.

•

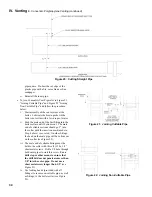

Follow flexible polypropylene pipe (liner)

manufacturer specific installation instructions

regarding application/listing, permits, minimum

clearances to combustibles; installation details

(proper joint assembly, pipe support and routing,

gasket and fitting installation, optional tooling

availability/usage, routing thru masonry chimney

for combustion product venting or, combination

of combustion product venting and combustion

air supply).

•

When there is a conflict between flexible

polypropylene pipe (liner) manufacturer installation

instructions and Apex boiler Installation, Operating

and Service Instructions, the more restrictive

instructions shall govern.

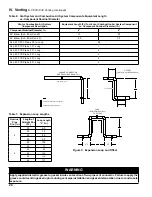

Apex Boiler Two-Pipe Vent System Connector Field

Modification Procedure To Accept Polypropylene

Vent Piping:

Apex boilers are factory supplied with a model-specific

boiler two-pipe CPVC/PVC vent system connector

shipped within a model-specific boiler CPVC gasketed

vent kit carton.

Locate and remove a model-specific boiler two-pipe

CPVC/PVC vent system connector.

When using M&G/DuraVent polypropylene pipe for

combustion product venting and/or air supply, male

PVC to PP boiler adapter (4PPS-04PVCM-4PPF or

6PPS-06PVCM-6PPF as applicable) is installed into the

two-pipe vent system connector vent or combustion air

supply port as follows (see Figure 14):

1)

APX399 and APX500 models

- Apply provided

dielectric grease (grease pouch taped to the vent

system connector) all around to the vent or air

connection inner red silicon gasket.

2)

APX399 and APX500 models

- Push and twist

PVC to PP boiler adapter (4PPS-04PVCM-4PPF)

into two-pipe vent system connector vent connection

or air supply port until bottomed out.

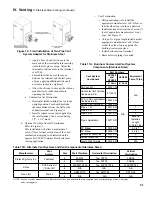

Boiler

Model

M&g / DuraVent Part numbers/Sizes

Male Boiler adapter,

PVC to PP

rigid Pipe

Flex Pipe

Pipe Joint

Locking Band

Side Wall

Termination Tee

Chimney Kit for

Venting Only

APX399

4PPS-04PVCM-4PPF

100 mm

100 mm

43PPS-LB

43PPS-TB

4PPS-FK

APX500

APX800

6PPS-06PVCM-6PPF

150 mm

N/A

6PPS-LBC

6PPS-E90B

N/A

Table 9: approved Polypropylene Pipe, Fittings and Terminations - M&g/DuraVent

Boiler

Model

Centrotherm Eco Part numbers/Sizes

Male Boiler adapter,

PVC to PP

rigid Pipe

Flex Pipe

Pipe Joint

Locking Band

Side Wall

Termination Tee

Chimney Kit for

Venting Only

APX399

ISAA0404

ISSAL0404

110 mm

110 mm

IANS04

ISTT0420

IFCK0425

and

IFCK0435

APX500

APX800

ISAA0606

ISSAL0606

160 mm

N/A

IANS06

ISTT0620

N/A

Table 10: approved Polypropylene Pipe, Fittings and Terminations - Centrotherm Eco

Summary of Contents for Apex APX399

Page 65: ...65 VIII Electrical continued Figure 43 Ladder Diagram ...

Page 66: ...66 VIII Electrical continued ...

Page 67: ...67 Figure 44 Wiring Connections Diagram VIII Electrical continued ...

Page 110: ...110 1P 3 1P 2 1P 1 XIII Repair Parts continued 1C 1D 1E ...

Page 116: ...116 XIII Repair Parts continued ...

Page 118: ...118 XIII Repair Parts continued ...

Page 129: ...129 SERVICE RECORD DATE SERVICE PERFORMED ...

Page 130: ...130 SERVICE RECORD DATE SERVICE PERFORMED ...