101

Xi. Service and Maintenance

nOTiCE

Warranty does not cover boiler damage or

malfunction if the following steps are not

performed at the intervals specified.

A.

Continuously:

1. Keep the area around the boiler free from

combustible materials, gasoline and other flammable

vapors and liquids.

2. Keep the area around the combustion air inlet

terminal free from contaminates .

3. Keep the boiler room ventilation openings open and

unobstructed.

B.

Monthly Inspections:

1. Inspect the vent piping and outside air intake piping

to verify they are open, unobstructed and free from

leakage or deterioration. Call the service technician

to make repairs if needed.

2. Inspect the condensate drain system to verify it is

leak tight, open and unobstructed. Call the service

technician if the condensate drain system requires

maintenance.

3. Inspect the flue temperature sensor cap to verify that

it is free from leakage and deterioration. Call the

Service Technician to make repairs, if needed.

4. Inspect the water and gas lines to verify they are

free from leaks. Call the service technician to make

repairs if required.

CaUTiOn

Water leaks can cause severe corrosion damage

to the boiler or other system components.

immediately repair any leaks found.

C.

Annual Inspections and Service:

In addition to

the inspections listed above the following should be

performed by a service technician once every year.

1. If equipped, test the low water cutoff by pressing the

“Test” button located at its end. The yellow light

should come on and “Limit Open” will flash in the

Active Faults screen on the display. Push the reset

button to restore normal operation. If yellow light

does not come on, determine why the low water

cutoff is not working properly.

2. Follow the procedure for turning the boiler off per

Figure 51 “Lighting Instructions”.

3. Inspect the wiring to verify the conductors are in

good condition and attached securely.

DangEr

This boiler uses flammable gas, high voltage electricity, moving parts, and very hot water under high

pressure. assure that all gas and electric power supplies are off and that the water temperature is cool

before attempting any disassembly or service.

Do not attempt any service work if gas is present in the air in the vicinity of the boiler. never modify,

remove or tamper with any control device.

Warning

This boiler must only be serviced and repaired by skilled and experienced service technicians.

if any controls are replaced, they must be replaced with identical models.

read, understand and follow all the instructions and warnings contained in all the sections of this

manual.

if any electrical wires are disconnected during service, clearly label the wires and assure that the wires

are reconnected properly.

never jump out or bypass any safety or operating control or component of this boiler.

read, understand and follow all the instructions and warnings contained in aLL of the component

instruction manuals.

assure that all safety and operating controls and components are operating properly before placing

the boiler back in service.

annually inspect all vent gaskets and replace any exhibiting damage or deterioration.

Summary of Contents for Apex APX399

Page 65: ...65 VIII Electrical continued Figure 43 Ladder Diagram ...

Page 66: ...66 VIII Electrical continued ...

Page 67: ...67 Figure 44 Wiring Connections Diagram VIII Electrical continued ...

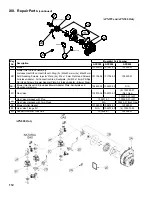

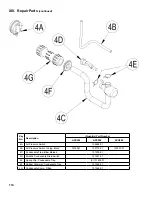

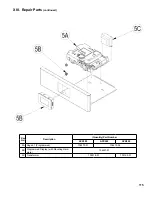

Page 110: ...110 1P 3 1P 2 1P 1 XIII Repair Parts continued 1C 1D 1E ...

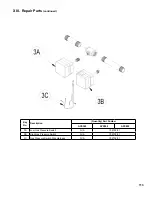

Page 116: ...116 XIII Repair Parts continued ...

Page 118: ...118 XIII Repair Parts continued ...

Page 129: ...129 SERVICE RECORD DATE SERVICE PERFORMED ...

Page 130: ...130 SERVICE RECORD DATE SERVICE PERFORMED ...