59

Vii. gas Piping

Warning

Failure to properly pipe gas supply to boiler may

result in improper operation and damage to the

boiler or structure. always assure gas piping is

absolutely leak free and of the proper size and

type for the connected load.

an additional gas pressure regulator may be

needed. Consult gas supplier.

Warning

Size corrugated stainless steel tubing (CSST)

to ensure proper capacity and minimize flow

restrictions.

A.

Size gas piping

. Design system to provide adequate gas

supply to boiler. Consider these factors:

1. Allowable pressure drop from point of delivery to

boiler. Maximum allowable system pressure is ½

psig. Actual point of delivery pressure may be less;

contact gas supplier for additional information.

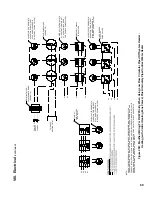

inlet Pressure 0.5 PSi or less; 0.3 inch W.C. Pressure Drop

nominal

Pipe Size, in.

inside

Diameter, in.

Length of Pipe, Ft.

10

20

30

40

50

60

70

80

90

100

½

0.622

131

90

72

62

55

50

46

42

40

38

¾

0.824

273

188

151

129

114

104

95

89

83

79

1

1.049

514

353

284

243

215

195

179

167

157

148

1¼

1.380

1056

726

583

499

442

400

368

343

322

304

1½

1.610

1582

1087

873

747

662

600

552

514

482

455

2

2.067

3046

2094

1681

1439

1275

1156

1063

989

928

877

2½

2.469

4856

3337

2680

2294

2033

1842

1695

1576

1479

1397

3

3.068

8584

5900

4738

4055

3594

3256

2996

2787

2615

2470

Table 19a: Maximum Capacity of Schedule 40 Black Pipe in CFH* (natural gas) For gas Pressures

of 0.5 psig or Less

inlet Pressure 0.5 PSi or less; 0.5 inch W.C. Pressure Drop

nominal

Pipe Size, in.

inside

Diameter, in.

Length of Pipe, Ft.

10

20

30

40

50

60

70

80

90

100

½

0.622

172

118

95

81

72

65

60

56

52

50

¾

0.824

360

247

199

170

151

137

126

117

110

104

1

1.049

678

466

374

320

284

257

237

220

207

195

1¼

1.380

1392

957

768

657

583

528

486

452

424

400

1½

1.610

2085

1433

1151

985

873

791

728

677

635

600

2

2.067

4016

2760

2217

1897

1681

1523

1402

1304

1223

1156

2½

2.469

6401

4400

3533

3024

2680

2428

2234

2078

1950

1842

3

3.068

11316

7778

6246

5345

4738

4293

3949

3674

3447

3256

* 1 CFH of Natural Gas is approximately equal to 1 MBH; contact your gas supplier for the actual heating value of your

gas.

Minimum gas valve inlet pressure is stamped on

the rating label located in the boiler’s vestibule

compartment.

2. Maximum gas demand. Refer to the boiler’s input as

printed on its rating label. Also consider existing and

expected future gas utilization equipment (i.e. water

heater, cooking equipment).

3. Length of piping and number of fittings. Refer

to Tables 19A (natural gas) or 19B (LP gas) for

maximum capacity of Schedule 40 pipe. Table 20

lists equivalent pipe length for standard fittings.

4. Specific gravity of gas. Gas piping systems for gas

with a specific gravity of 0.60 or less can be sized

directly from Tables 19A or 19B, unless authority

having jurisdiction specifies a gravity factor be

applied. For specific gravity greater than 0.60,

apply gravity factor from Table 21. If exact specific

gravity is not shown choose next higher value.

For materials or conditions other than those listed

above, refer to

National Fuel Gas Code

, NFPA

54/ANSI Z223.1, or size system using standard

engineering methods acceptable to authority having

jurisdiction.

Summary of Contents for Apex APX399

Page 65: ...65 VIII Electrical continued Figure 43 Ladder Diagram ...

Page 66: ...66 VIII Electrical continued ...

Page 67: ...67 Figure 44 Wiring Connections Diagram VIII Electrical continued ...

Page 110: ...110 1P 3 1P 2 1P 1 XIII Repair Parts continued 1C 1D 1E ...

Page 116: ...116 XIII Repair Parts continued ...

Page 118: ...118 XIII Repair Parts continued ...

Page 129: ...129 SERVICE RECORD DATE SERVICE PERFORMED ...

Page 130: ...130 SERVICE RECORD DATE SERVICE PERFORMED ...