33

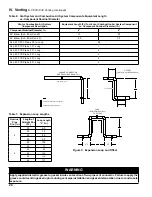

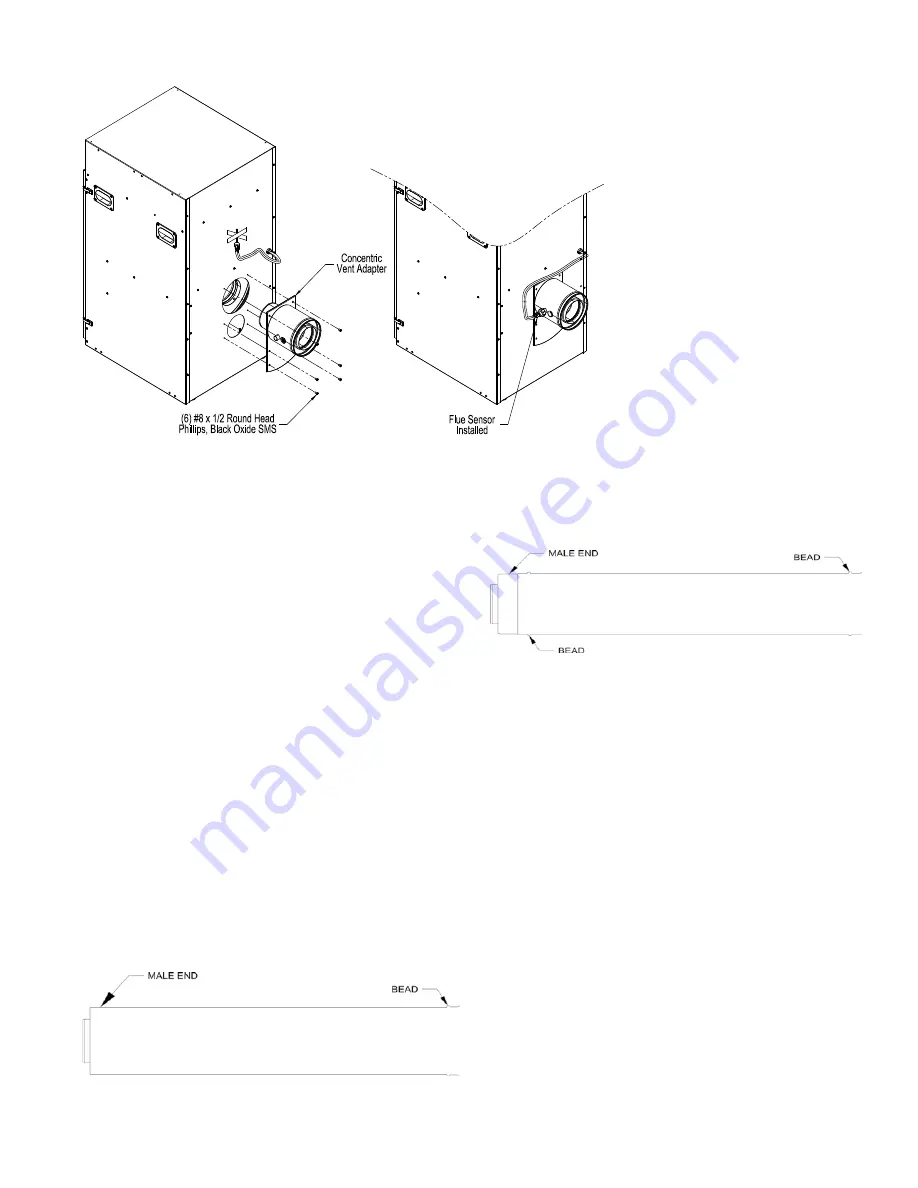

c. Align collar plate clearance holes with rear/

bottom panel engagement holes; then secure the

collar to rear/bottom panel with six mounting

screws. See Figure 17.

d. Flue temperature sensor, factory attached to the

boiler wiring harness, is secured to the left boiler

jacket panel with tape.

e. Remove the tape and push the sensor rubber plug

into Concentric Vent Collar sensor port until the

plug is securely engaged. See Figure 17.

The installation of the Concentric Vent Collar is now

completed.

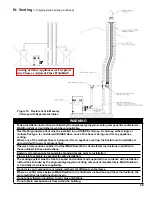

3.

System Assembly

a. Plan venting system to avoid possible contact

with plumbing or electrical wires. Start at

vent connector at boiler and work towards vent

termination.

b. Do not exceed maximum Concentric vent length.

Refer to Table 12.

c. If additional concentric vent piping is needed:

i.

Concentric Vent Cut-To-Length Extension

pipes,

identified in Table 13 CAN BE

CUT

to required length when used as an

extension.

These pipes have plain male

end and beaded female end.

Always cut

the pipe from plain male end.

See Figure

18 ‘Cut-To-Length Extension (Cuttable)”.

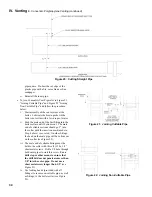

d. To cut the Concentric Vent Straight pipe to

required length refer to Figure 20 “Cutting

Straight Pipe” and the following procedure:

i.

Determine the required length of the outer

pipe. When doing this allow an additional

1” of length for insertion into the female end

of the adjoining pipe. Mark the cut line on

the outer pipe.

ii.

Remove the plastic inner pipe by pulling it

out from the female end.

iii.

Cut the

OUTER PIPE ONLY

at the point

marked in Step (a) using aviation shears, a

hacksaw, or an abrasive wheel cutter. Be

careful to cut the pipe square. De-burr the

cut end with a file or emery cloth.

iv.

Make an insertion mark 1” from the male

end of the outer pipe.

v.

Cut the plastic inner pipe so that it will

protrude 3/8” beyond the male end of the

outer pipe when reinstalled in the outer pipe.

Use a fine tooth hacksaw or a PVC saw to

cut the plastic pipe and be careful to cut the

Figure 17: Field installation of Boiler

Concentric Vent Collar

iV. Venting

E. Concentric Polypropylene Venting (continued)

Figure 18: Cut-To-Length Extension (Cuttable)

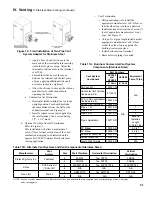

ii.

The remaining Concentric Vent Fixed

Extensions shown in Table 13 CANNOT

BE CUT. These pipes have beaded male and

beaded female ends. See Figure 19 “Fixed

Extension (Non-Cuttable)’.

Figure 19: Fixed Extension (non-Cuttable)

Summary of Contents for Apex APX399

Page 65: ...65 VIII Electrical continued Figure 43 Ladder Diagram ...

Page 66: ...66 VIII Electrical continued ...

Page 67: ...67 Figure 44 Wiring Connections Diagram VIII Electrical continued ...

Page 110: ...110 1P 3 1P 2 1P 1 XIII Repair Parts continued 1C 1D 1E ...

Page 116: ...116 XIII Repair Parts continued ...

Page 118: ...118 XIII Repair Parts continued ...

Page 129: ...129 SERVICE RECORD DATE SERVICE PERFORMED ...

Page 130: ...130 SERVICE RECORD DATE SERVICE PERFORMED ...