31

Red LED-Status

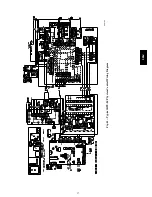

C08452

Fig. 40 -- Integrated Gas Control (IGC) Board

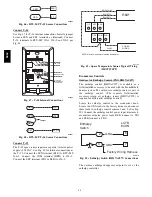

Table 10 – IGC Connections

TERMINAL LABEL

POINT DESCRIPTION

SENSOR LOCATION

TYPE OF I/O

CONNECTION

PIN NUMBER

INPUTS

RT, C

Input power from TRAN 1

control box

24 VAC

—

SS

Speed sensor

gas section

analog input

J1, 1-3

FS, T1

Flame sensor

gas section

switch input

—

W

Heat stage 1

LCTB

24 VAC

J2, 2

RS

Rollout switch

gas section

switch input

J2, 5-6

LS

Limit switch

fan section

switch input

J2, 7-8

CS

Centrifugal switch (not used)

—

switch input

J2, 9-10

OUTPUTS

L1, CM

Induced draft combustion motor

gas section

line VAC

IFO

Indoor fan

control box

relay

J2, 1

GV

Gas valve (heat stage 1)

gas section

relay

J2, 11-12

580J

Summary of Contents for 580J*08--14D

Page 10: ...10 COOLING CHARGING CHARTS C09221 Fig 10 Cooling Charging Charts 08D F Both Circuits 580J ...

Page 11: ...11 COOLING CHARGING CHARTS C09222 Fig 11 Cooling Charging Charts 12D F Both Circuits 580J ...

Page 36: ...36 C07129 Fig 42 RTU MP Multi Protocol Control Board 580J ...

Page 37: ...37 C09163 Fig 43 Typical RTU MP System Control Wiring Diagram 580J ...

Page 60: ...60 C09156 Fig 73 580J Typical Unit Wiring Diagram Power 08D F 208 230 3 60 580J ...

Page 61: ...61 C09157 Fig 74 580J Typical Unit Wiring Diagram Control 08 12D F 208 230 3 60 580J ...

Page 84: ...84 580J ...