24

Table 3 – Detector Indicators

CONTROL OR INDICATOR

DESCRIPTION

Magnetic test/reset switch

Resets the sensor when it is in the alarm or trouble state. Activates or tests the sensor when it is in

the normal state.

Alarm LED

Indicates the sensor is in the alarm state.

Trouble LED

Indicates the sensor is in the trouble state.

Dirty LED

Indicates the amount of environmental compensation used by the sensor

(flashing continuously = 100%)

Power LED

Indicates the sensor is energized.

Controller’s Power LED is Off

1. Make sure the circuit supplying power to the control-

ler is operational. If not, make sure JP2 and JP3 are

set correctly on the controller before applying power.

2. Verify that power is applied to the controller’s supply

input terminals. If power is not present, replace or re-

pair wiring as required.

Remote Test/Reset Station’s Trouble LED Does Not

Flash When Performing a Dirty Test, but the

Controller’s Trouble LED Does

1. Verify that the remote test/station is wired as shown

in Fig. 27. Repair or replace loose or missing wiring.

2. Configure the sensor dirty test to activate the control-

ler’s supervision relay. See “Changing Sensor Dirty

Test Operation.”

Sensor’s Trouble LED is On, But the Controller’s

Trouble LED is OFF

Remove JP1 on the controller.

PROTECTIVE DEVICES

Compressor Protection

Overcurrent

Each compressor has internal linebreak motor protection.

Reset is automatic after compressor motor has cooled.

Overtemperature

Each compressor has an internal protector to protect it

against excessively high discharge gas temperatures. Reset

is automatic.

High Pressure Switch

Each system is provided with a high pressure switch

mounted on the discharge line. The switch is

stem--mounted and brazed into the discharge tube. Trip

setting is 630 psig +/-- 10 psig (4344 +/-- 69 kPa) when

hot. Reset is automatic at 505 psig (3482 kPa).

Low Pressure Switch

Each system is protected against a loss of charge and low

evaporator coil loading condition by a low pressure switch

located on the suction line near the compressor. The

switch is stem--mounted. Trip setting is 54 psig +/-- 5 psig

(372 +/-- 34 kPa). Reset is automatic at 117 +/-- 5 psig

(807 +/-- 34 kPa).

Supply (Indoor) Fan Motor Protection

Disconnect and lockout power when servicing fan motor.

The supply fan motor is equipped with an overcurrent

protection device. The type of device depends on the

motor size. (See Table 4.)

Table 4 – Supply Fan Motor Protection Devices

Motor Size

(bhp)

Overload Device

Reset

1.7

Internal Linebreak

Automatic

2.4

Internal Linebreak

Automatic

2.9

Thermik

Automatic

3.7

Thermik

Automatic

5.2

External

(Circuit Breaker)

Manual

The Internal Linebreak type is an imbedded switch that

senses both motor current and internal motor temperature.

When this switch reaches its trip setpoint, the switch

opens the power supply to the motor and the motor stops.

Reset is automatic when the motor windings cool down.

The Thermik device is a snap--action overtemperature

protection device that is imbedded in the motor windings.

It is a pilot--circuit device that is wired into the unit’s 24--v

control circuit. When this switch reaches its trip setpoint,

it opens the 24--v control circuit and causes all unit

operation to cease. This device resets automatically when

the motor windings cool. Do not bypass this switch to

correct trouble. Determine the cause and correct it.

The

External

motor

overload

device

is

a

specially--calibrated circuit breaker that is UL recognized

as a motor overload controller.

It is an overcurrent

device.

When the motor current exceeds the circuit

breaker setpoint, the device opens all motor power leads

and the motor shuts down. Reset requires a manual reset

at the overload switch. This device (designated IFCB) is

located on the side of the supply fan housing, behind the

fan access panel.

580J

Summary of Contents for 580J*08--14D

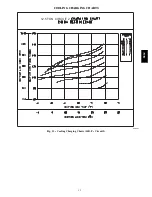

Page 10: ...10 COOLING CHARGING CHARTS C09221 Fig 10 Cooling Charging Charts 08D F Both Circuits 580J ...

Page 11: ...11 COOLING CHARGING CHARTS C09222 Fig 11 Cooling Charging Charts 12D F Both Circuits 580J ...

Page 36: ...36 C07129 Fig 42 RTU MP Multi Protocol Control Board 580J ...

Page 37: ...37 C09163 Fig 43 Typical RTU MP System Control Wiring Diagram 580J ...

Page 60: ...60 C09156 Fig 73 580J Typical Unit Wiring Diagram Power 08D F 208 230 3 60 580J ...

Page 61: ...61 C09157 Fig 74 580J Typical Unit Wiring Diagram Control 08 12D F 208 230 3 60 580J ...

Page 84: ...84 580J ...