4

For best efficiency and performance, the least

amount of convection air possible should be

used. Optimal energy efficiency is achieved

when the majority of energy transfer from

heating elements to product occurs through

radiation. Convection air tends to decrease the

overall efficiency of this process, and should

thus only be used when required.

Exhaust and Cooler:

The exhaust and cooler settings are also

contained in each program, such that certain

products may have these fans turned on while

other products may have them turned off. Use of

the exhaust and cooler fans is optional.

Bulb Powers:

The Firefly Curing System has the ability to set

independent bulb powers for every bulb in the

system. These powers are set using the expanded

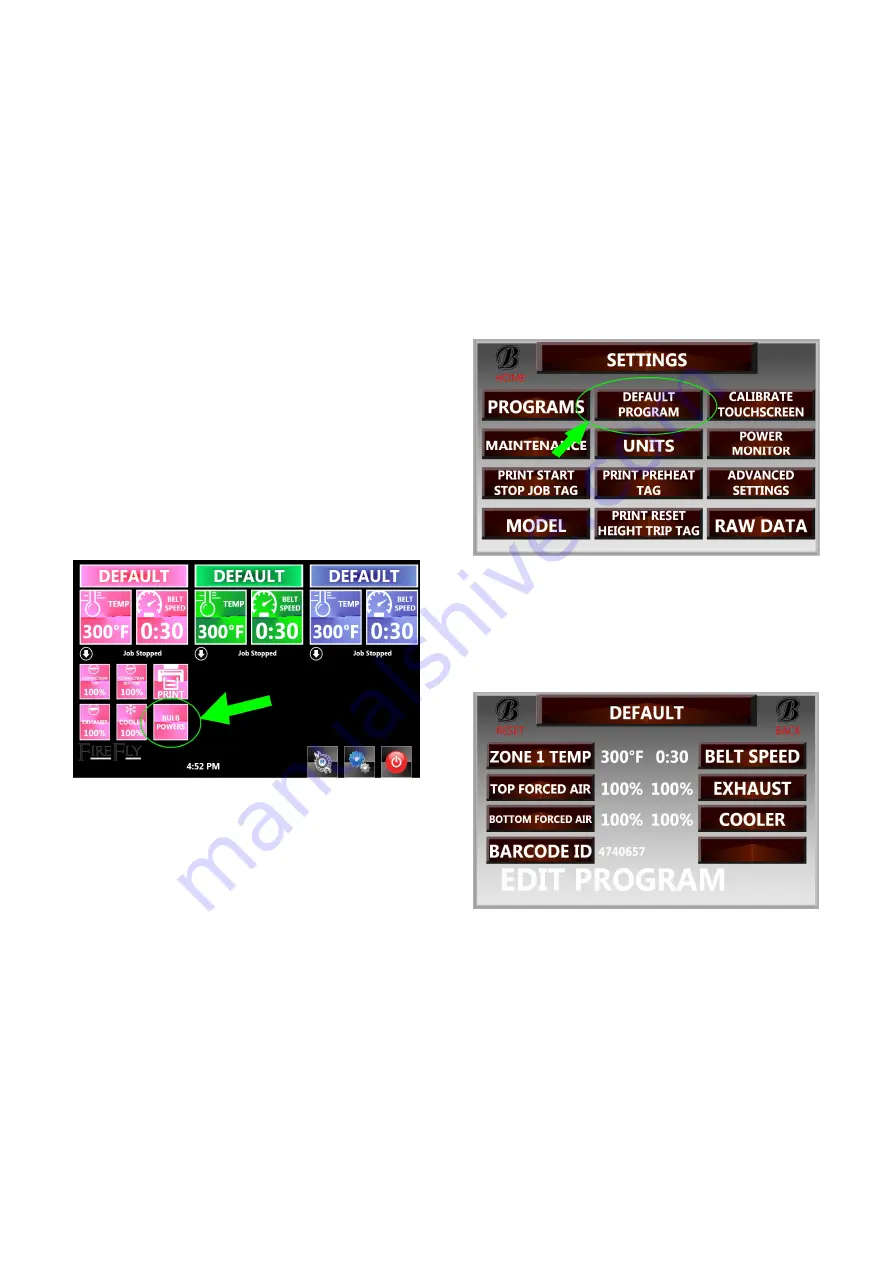

program options on the main screen (Figure 3)

Figure 3: Bulb Powers Option

Controlling the bulb powers allows for great

flexibility in managing the intensity of heat in

the system. Setting all bulb powers at 100%

ensures maximum intensity heat for maximum

production throughput. Lower power settings

allows for moderate intensity heat for delicate

applications. Varying powers can be set to

optimize specific jobs, such as setting high bulb

powers on the front few bulbs to act as an initial

“bump”, and setting the rest of the bulbs lower to

maintain the cure temperature while minimizing

any possible overshoot.

Generally slower belt speeds require lower bulb

powers, whereas faster belt speeds require higher

bulb powers.

Default Program:

When the Firefly Curing System first powers on,

every belt loads the “Default” program cure

parameters. These parameters may be adjusted at

the main control Kiosk by choosing “Settings”

→

“Default Program” (Figure 4)

Figure 4: Default Program Button

In the Default Program Screen (Figure 5), the

default cure parameters may be adjusted. If

adjustments are made, the “Back” button will

change to “Save”. Press the “Save” button to

save changes, or “Reset” to discard changes.

Figure 5: Default Program Screen