App. 2-7

A2.4 Updating Correction Value for Multiplying

Factor of Horizontal Scanning, Stored in the

Facsimile Machine

To keep the scanning quality in reduction/enlargement copying, the controller compensates the

multiplying factor of horizontal scanning according to the correction value stored in the EEPROM

of the driver PCB.

If you replace the CCD unit, scanner unit, or driver PCB of the machine, then you need to update

the correction value for the multiplying factor of horizontal scanning according to the procedure

given below.

TIP:

The updating procedure given here needs entry to the maintenance mode. Refer to

CHAPTER 7, Subsection 7.5.11.

(1) After completion of replacement of the CCD unit, scanner unit, or driver PCB, plug the

machine's power cord into a wall socket and then turn on the facsimile machine.

The LCD shows the number of pixels.

(2) According to the number of pixels displayed, obtain the new correction value from the

correction table given on the next page.

(3) Make the machine enter the maintenance mode (refer to CHAPTER 7, Section 7.2) and then

press the

5

key twice (Subsection 7.5.11).

The machine checks and sets the area to be scanner. After that, it becomes ready to accept a

new correction value.

(4) Enter the new correction value obtained in step (2) above.

Press the

Stop

key to return to the initial stage of the maintenance mode, then press the

9

key

twice to exit from the maintenance mode.

Summary of Contents for MFC-5200C

Page 1: ...FACSIMILE EQUIPMENT SERVICE MANUAL MODEL MFC5200C MFC890 ...

Page 7: ...CHAPTER 1 PARTS NAMES FUNCTIONS ...

Page 8: ...CHAPTER 1 PARTS NAMES FUNCTIONS CONTENTS 1 1 EQUIPMENT OUTLINE 1 1 1 2 CONTROL PANEL 1 3 ...

Page 13: ...CHAPTER 2 SPECIFICATIONS ...

Page 18: ...2 4 2 1 4 Environmental Condition ...

Page 23: ...CHAPTER 3 INSTALLATION ...

Page 26: ...3 2 3 2 UNPACKING THE MACHINE The equipment consists of the following major components ...

Page 34: ...CHAPTER 4 THEORY OF OPERATION ...

Page 54: ...CHAPTER 5 MAINTENANCE ...

Page 60: ...CHAPTER 6 DISASSEMBLY REASSEMBLY LUBRICATION AND ADJUSTMENT ...

Page 141: ...6 79 2 Separation roller and document feed roller 3 Document ejection roller ...

Page 146: ...6 84 11 Purge shaft EM4 Main chassis ...

Page 151: ...CHAPTER 7 MAINTENANCE MODE ...

Page 160: ...7 8 Scanning Compensation Data List ...

Page 174: ...7 22 Vertical Alignment Check Pattern ...

Page 183: ...CHAPTER 8 ERROR INDICATION AND TROUBLESHOOTING ...

Page 213: ...8 29 4 Close the manual feed cover ...

Page 214: ...MFC5200C MFC890 Appendix 1 Serial No Descriptions ...

Page 216: ... 2 PRINTER HEAD UNIT Location ...

Page 228: ...MFC5200C MFC890 Appendix 3 EEPROM Customizing Codes ...

Page 231: ...MFC5200C MFC890 Appendix 4 Firmware Switches WSW ...

Page 274: ...MFC5200C MFC890 Appendix 5 Re Packing Instructions ...

Page 276: ... 8 Place the machine in the original box with the original packaging material ...

Page 277: ...MFC5200C MFC890 Appendix 6 Wiring Diagram ...

Page 280: ...A Main PCB 1 4 MFC5200C ...

Page 281: ...A Main PCB 2 4 MFC5200C ...

Page 282: ...A Main PCB 3 4 MFC5200C ...

Page 283: ...A Main PCB 4 4 MFC5200C ...

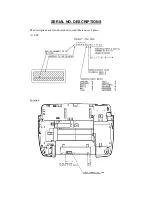

Page 284: ...B Driver PCB 1 2 ...

Page 285: ...B Driver PCB 2 2 ...

Page 286: ...C NCU PCB MFC5200C ...

Page 287: ...D Control Panel PCB 1 2 MFC5200C ...

Page 288: ...D Control Panel PCB 1 2 MFC890 ...

Page 289: ...D Control Panel PCB 2 2 ...

Page 290: ...E Power Supply PCB MFC5200C ...

Page 291: ...F Carriage PCB ...

Page 292: ...G Media PCB 1 2 ...

Page 293: ...G Media PCB 2 2 ...