153

I20683 - Subject to change.

Wiring Guide

Analog Outputs

III. ANALOG OUTPUTS

III-A. 2 to 10 Volt Analog Output

The controller produces a variable voltage between signal common and the analog output.

The signal common (wire #1) of the actuator must be connected to the signal common of the controller, and the output of the con-

troller is connected to actuator signal input (wire #3).

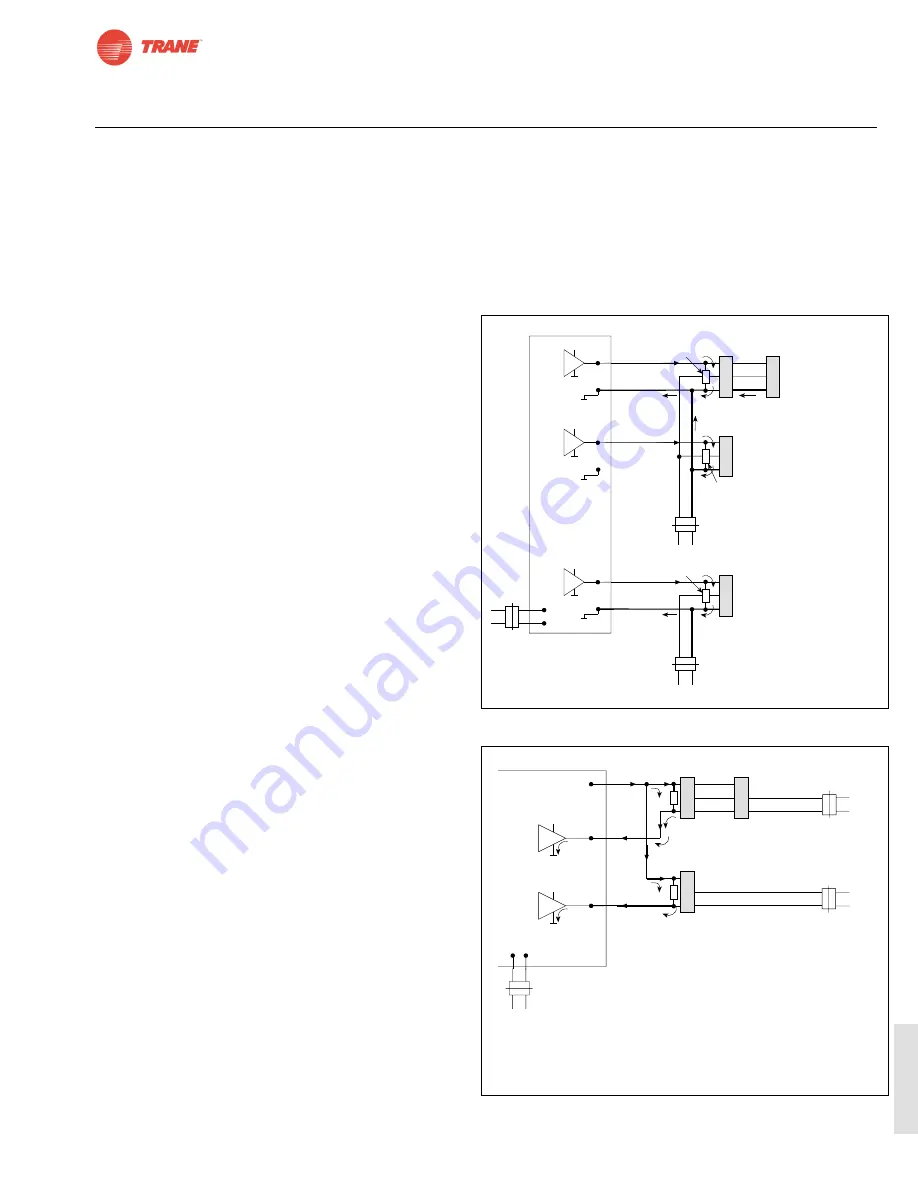

III-B. Sourcing 4 to 20 mA Analog Output

A sourcing 4 to 20mA analog output sends out a current to the

actuator, and receives it at the signal common terminal.

It is similar to a 0 to 10 V output. The only difference is that

one 500

Ω

resistor has to be installed between wires #3 and

#1 at the actuator. The resistor converts the current (4 to 20

mA) to a 2 to 10 V signal. The resistor should be located at

the actuator.

III-C. Sinking 4 to 20 mA Analog Output

A sinking 4 to 20 mA output uses a different logic to create a

control signal. In both a 0 to 10 VDC and sourcing 4 to 20

mA application, the signal is regulated at the positive (+)

source of the signal. In a sinking application the signal is reg-

ulated between the device being controlled and common.

For this reason, the term “Output” in a sinking application is

sometimes confusing.

The controller has one terminal that supplies a constant DC

voltage (often +24V). The input of the actuators (wire #3) are

connected to the constant voltage. A 500

Ω

resistor is con-

nected between wires #1 and #3 on one actuator connected

to each output. (One resistor for each output.) Terminal #1

on the actuator is connected to the output of the controller.

The current will run from the constant voltage on the con-

troller, to wire #3 on the actuator, through the 500

Ω

resistor,

to wire #1, and back to the input of the controller.

From the controllers point of view, all the #3 terminals of the

actuators are at a “common” co24VDC. The signal

common, wire #1, of the actuators will vary with the control

signal.

Because the signal common of the actuators is variable, each

output requires a separate transformer. The signal common

of actuators connected to different outputs must never be

interconnected. (See note ** in the wiring diagram)

Fig III-1

Control Output

Sourcing 4 to 20 mA

L

I

N

E

It is possible to use one

transformer, for actuators

connected to different outputs.

(Connect #1 of one actuator to

minus (COM) on the controller.)

Each transformer needs to be

connected (via wire #1 of one

actuator) to minus (COM) on

the controller.

Only one 500 resistor should

be used for multiple actuators

wired in parallel. Up to four

actuators may be wired in

parallel to the 500

resistor.

*

**

***

(+)

(–)

3

2

1

(+)

(–)

4 to 20 mA

COM

⊥

**

LOAD

RESISTOR

500 , 0.5W

TRANSFORMER

#2

COM

⊥

24 V

A

C

HOT

~

L I N E

+

(+)

(–)

3

2

1

(+)

(–)

4 to 20 mA

LOAD

RESISTOR

500 , 0.5W

TRANSFORMER

#1

COM

⊥

24 V

A

C

HOT

~

L I N E

+

(+)

(–)

3

2

1

(+)

(–)

4 to 20 mA

COM

⊥

OUTPUT 1

LOAD

RESISTOR

500 , 0.5W

+

3

2

1

***

OUTPUT 2

OUTPUT 3

ALWAYS USE A SEPARATE

TRANSFORMER FOR THE

CONTROLLER UNLESS YOU

KNOW A HALF-WAVE

RECTIFIER IS USED!

ACTUATOR

ACTUATOR

ACTUATOR

ACTUATOR

*

Fig. III-2 Sinking 4 to 20 mA

+

HOT ~

24 VAC

COM

⊥

3

2

1

3

2

1

3

2

1

Sinking 4 to 20mA

Controller

POWER

SUPPLY

+ 24V DC

(Typically)

4 to 20 mA

4 to 20 mA

Transformer #1

Transformer #2

*

**

500

500

2 to 10V

+

SINKING

OUTPUT 2

SINKING

OUTPUT 1

(–) (+)

L

I

N

E

L I N E

L

I

N

E

ALWAYS USE A SEPARATE

TRANSFORMER FOR THE

CONTROLLER UNLESS YOU

KNOW A HALF-WAVE

RECTIFIER IS USED!

ACTUATOR

ACTUATOR

ACTUATOR

HOT ~

24 VAC

COM

⊥

It is possible to connect two or more actuators to one transformer,

provided that the actuators are served by the same output.

Each output requires its own transformer.

*

**

(If actuators which are connected to different sinking outputs are

powered, by mistake, from the same transformer, all the actuators

will respond to the average of the output signals. This can be

very deceptive, because when one output signal is changed the

corresponding actuator will move, giving the false impression that

the system works. The problem is that the other actuators will

also move, although they belong to other control loops. For

example: Instead of operating the heating and cooling valves

and dampers in sequence, the valves and dampers will operate

at the same time, which is the wrong control sequence.)

Summary of Contents for TRANE TAF Series

Page 7: ...Notes Work Pad 7 I20683 Subject to change...

Page 27: ...27 I20683 Subject to change TAF Notes Work Pad...

Page 57: ...57 I20683 Subject to change TLF Notes Work Pad...

Page 73: ...73 I20683 Subject to change TTF Notes Work Pad...

Page 98: ...98 I20683 Subject to change Notes Work Pad...

Page 165: ...165 I20683 Subject to change Wiring Guide Notes Work Pad...

Page 166: ...Notes Work Pad 166 I20683 Subject to change...