Section G. Maintenance Belarus– 510/512 Operating manual

106

Special maintenance

After each 2,000 service hours.

Operation 44. Checking engine injec-

tors

IMPORTANT!

The injectors must be

cleaned and adjusted in a dealer’s spe-

cialized workshop.

WARNING:

Diesel fuel is injected under

high pressure and can result in serious

injuries, if the injector atomization is

checked by hand. Use a piece of paper

or cardboard for this purpose. Wear

protective goggles. Prior to connection

or disconnection of fuel lines, stop the

engine to take pressure down. Prior to

starting the engine, tighten all connec-

tions of fuel lines. In case of fuel injec-

tion on the hand skin, immediately ap-

ply for medical aid, otherwise blood

poisoning is possible.

NOTE:

It is convenient to have a spare

set of injectors verified and adjusted

for quick installation into the engine.

Take the injectors out and replace them

proceeding as follows.

• Prior to disconnection or loosening

of any fuel system parts, thoroughly

clean the adjacent working surfaces.

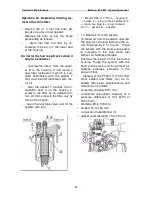

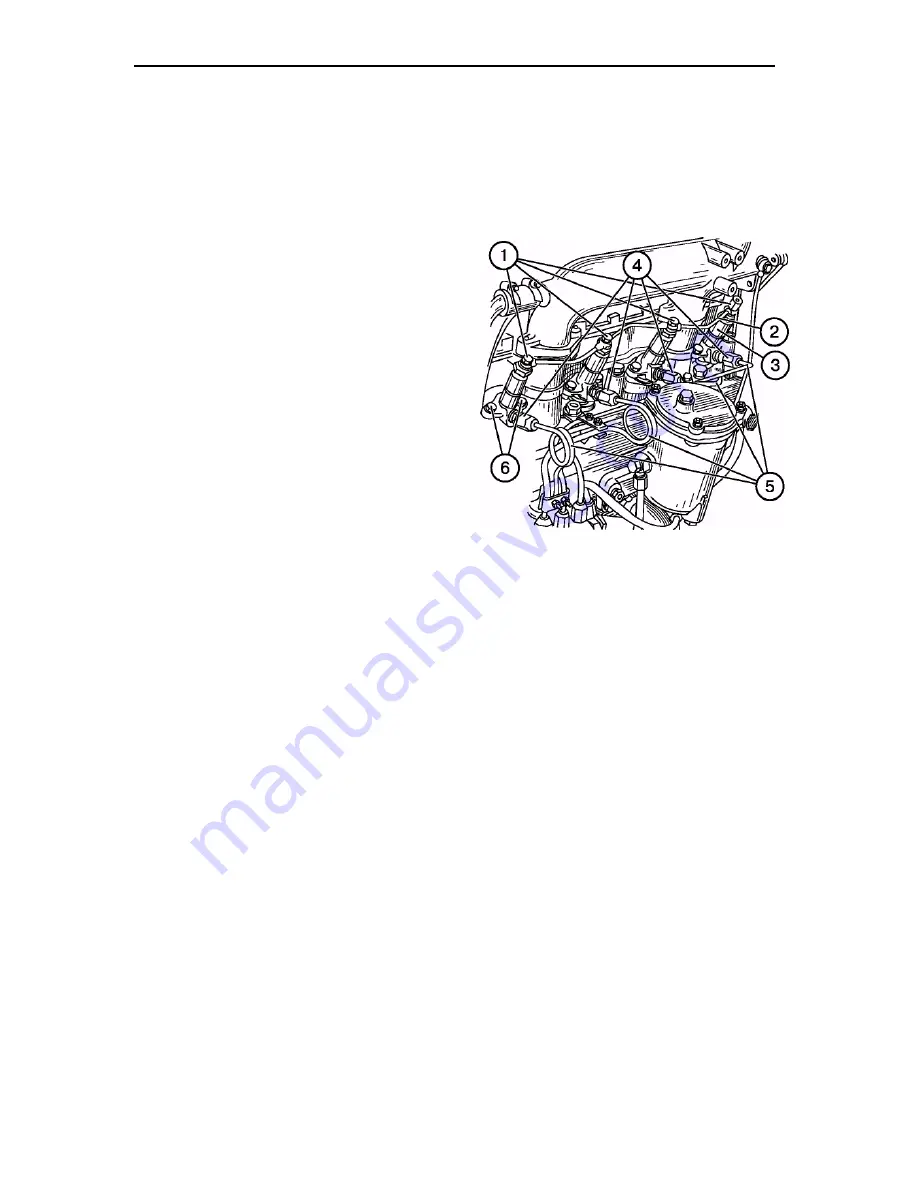

• Unscrew the nuts (4) and disconnect

the high-pressure fuel piping (5) from

the injectors (3) and fuel pump.

• Remove the fuel piping.

• Unscrew the four bolts (1) of the

drain line and take the rundown fuel

piping (2) away. Discard copper

sealing washers (two washers per

each banjo bolt).

• Unscrew the bolts (6) fastening the in-

jectors and remove the injectors (3).

• Send the injectors for servicing to

dealers workshop.

• Install the verified, cleaned and ad-

justed injectors by performing the

above specified step in the reverse

order.

• Remove air from the system.

IMPORTANT!

During each injector in-

stallation, use new copper washers.