8. Final Adjustment and Configuration

OverView D 50" – DOC-3303-5 – installation manual – Revision 10 – September 2006

September 2006

September 2006

September 2006 ________________________________

________________________________

________________________________

________________________________________________________

________________________

________________________

________________________8-21

Figure 8-26

message at dimmer range limit

Please note: this error message does not indicate a dimmer failure!

This message indicates that the dimmer cannot achieve the desired value but operates

at his limits (100%, or 50% respectively).

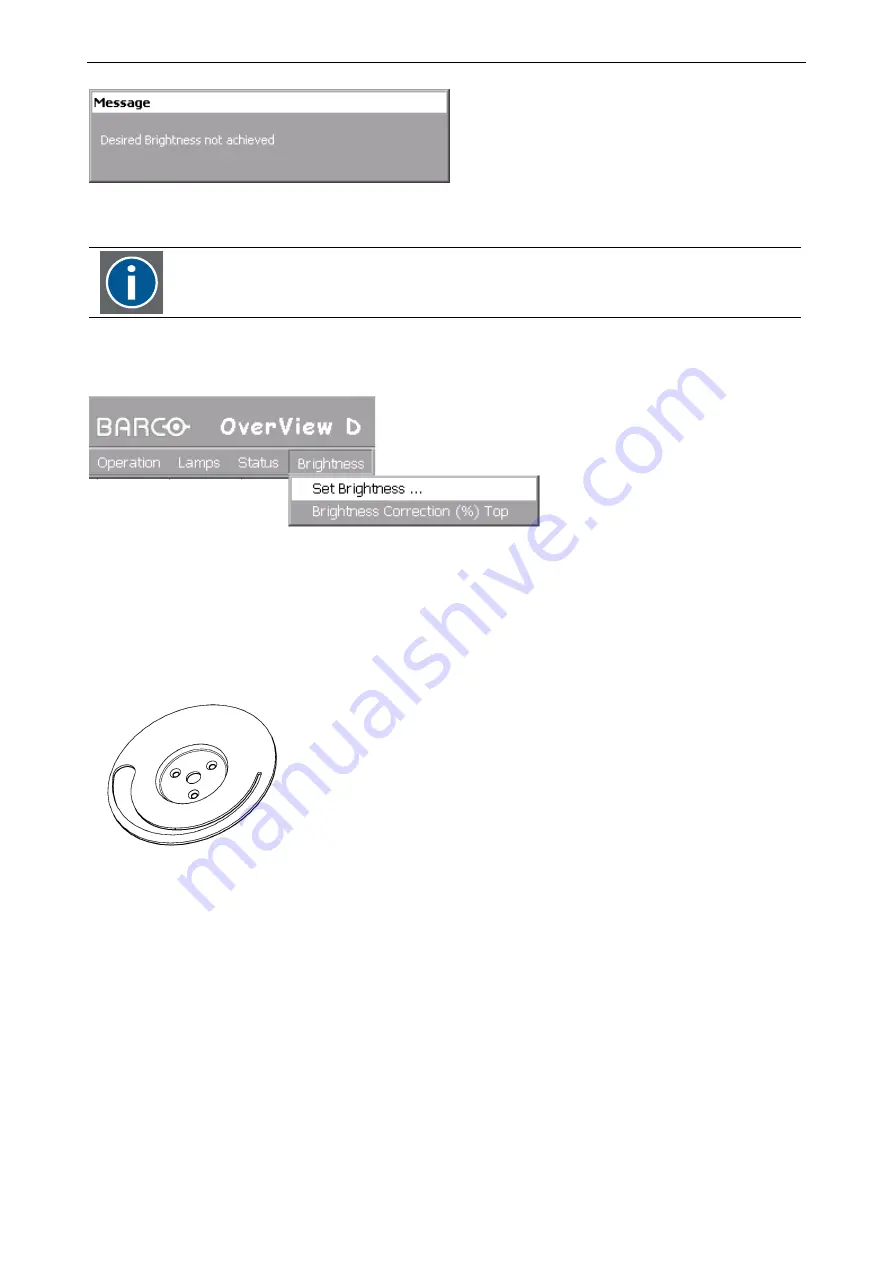

In this operation mode, the commands of the Brightness menu are available:

Figure 8-27

Brightness menu commands are available

8.5.4.5

Optical Dimmer

OverView D uses a dimmer wheel with a variable slit. The slit defines the light aperture of the light pipe entry.

Figure 8-28

Dimmer Wheel, variable slit

The amount of light emitted into the projection unit depends on the position (i.e. slit width) of the dimmer

wheel.