YORK INTERNATIONAL

76

this point, the chiller will shutdown. Restart will occur

automatically, when temperature falls more than 1°C

below the cutout and cooling demand is present.

This cutout is normally set at 54°C to allow operation

to the absolute maximum temperature capability of the

electromechanical components; however, values be-

tween 37.8 and 54.4°C are acceptable.

Low Ambient Temperature Cutout:

The low ambient temperature cutout is used to select

the ambient temperature below which the chiller may

not operate. If the ambient temperature falls 1°C be-

low this point, the chiller will shutdown. Restart will

occur automatically, when temperature rises more than

1°C above the cutout and cooling demand is present.

If the Dip Switch (S1) on the AMB board is set for

‘STANDARD AMBIENT CONTROL’ the low am-

bient temperature cutout is set at -4°C and is not pro-

grammable.

If the Dip Switch (S1) on the AMB board is set for ‘LOW

AMBIENT CONTROL’, programming of the cutout

between -17.8°C and 10°C is allowed. This allows higher

values than -3.9°C to be programmed to shutdown the

chiller when other cooling methods become operational.

Values below -3.9°C can be used for applications re-

quiring chiller operation at lower temperatures.

Low Leaving Liquid Temperature Cutout:

The low leaving liquid temperature cutout protects the

evaporator from damage due to ice build up caused by

operation below the chilled liquid freezing point.

If the leaving chilled liquid temperature (water or gly-

col) drops below the cutout point, the chiller will shut-

down. The chiller will restart automatically when tem-

perature rises more than 2°C above the cutout point

and cooling demand exists.

If the Dip Switch (S1) on the AMB board is set for

‘WATER’ cooling mode, the cutout is automatically

set at 2.2°C and cannot be reprogrammed.

If the Dip Switch (S1) on the AMB board is set for ‘GLY-

COL’ (Brine) cooling mode, the cutout can be pro-

grammed between -13.3°C and -2.2°C. The cutout should

normally be set to 2°C below the setpoint minus the

range, i.e. 0°C (setpoint) - 1°C (range) - 2°C = -3°C.

High Motor Current Unload Point:

The motor current unload point is used to avoid a high

motor current safety shutdown by unloading a com-

pressor, if current draw approaches the maximum limit

cutout value. The chiller can then continue to run auto-

matically at reduced capacity until the cause of the ex-

cessive current is resolved.

The microprocessor will accept between 30 - 105% for

the unload point. The motor current safety will shut

the compressor down whenever current exceeds 115%.

If the programmable limit is set between 100% and

105% of full load current, this safety will protect against

excessive current causing compressor shutdown due

to extremely high ambient, high chilled liquid tempera-

ture, and condenser malfunction caused by dirt or fan

problems.

If the programmable limit is set below 100% of full

load current, this feature can be used for ‘demand lim-

iting’. This is important when demand limiting is criti-

cal due to power requirements or limitations in the

building.

For the first 60 seconds of operation, the unloading

safety is disabled. After this time, if motor current ex-

ceeds the programmed limit, slide valve current will

be slowly reduced until the motor current drops below

the programmed limit. Additional loading will take

place when motor current drops below 90% of the pro-

grammed threshold.

Typically, this point should be set at 100% for maxi-

mum motor protection, programming for 100% is ad-

visable. When programming values below 100% use

of a leading ‘0’ is required, e.g. 085%.

Anti-Recycle Time:

The anti-recycle timer controls the minimum time be-

tween starts for each compressor. This is the time avail-

L O W

A M B I E N T

T E M P

C U T O U T

=

4 . 0 ° C

L E A V I N G

L I Q U I D

T E M P

C U T O U T

=

2 . 0 ° C

H I G H

M O T O R

C U R R E N T

U N L O A D

=

1 0 0 %

F L A

A N T I

R E C Y C L E

T I M E R

=

6 0 0

S E C S

Micropanel

Содержание YCWS0313SC

Страница 12: ...YORK INTERNATIONAL 12 THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN PAGE FORMAT...

Страница 36: ...YORK INTERNATIONAL 36 THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN PAGE FORMAT Commissioning...

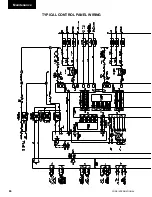

Страница 86: ...YORK INTERNATIONAL 86 TYPICAL CONTROL PANEL WIRING Maintenance...

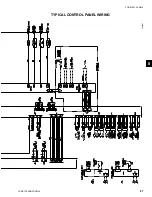

Страница 87: ...FORM 201 24 NM2 87 YORK INTERNATIONAL TYPICAL CONTROL PANEL WIRING LD06957 8...

Страница 91: ...FORM 201 24 NM2 91 YORK INTERNATIONAL THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN PAGE FORMAT 9...

Страница 101: ...FORM 201 24 NM2 101 YORK INTERNATIONAL SECTION 10 SPARE PARTS This information will be available at a later date 10...

Страница 103: ...FORM 201 24 NM2 103 YORK INTERNATIONAL NOTES 11...