FORM 201.24-NM2

15

YORK INTERNATIONAL

The automatic spring return of the capacity control

valve to the minimum load position will ensure com-

pressor starting at minimum motor load.

OIL SEPARATOR

Each circuit has a high efficiency, augmented gas im-

pingement type oil separator to maximize oil extrac-

tion without fragile media to break down.

The oil separator, is mounted in the discharge line of

the compressor. The high pressure discharge gas is

forced around a 90 degree bend. Oil is forced to the

outside of the separator through centrifugal action and

captured on wire mesh where it drains to the bottom of

the oil separator and into the compressor.

The oil drains back into the compressor through a re-

placeable 0.5-3.0 micron oil filter, and oil supply sole-

noid, is at high pressure. This high pressure “oil injec-

tion” forces the oil into the compressor where it is grav-

ity fed to the rotors and bearings for lubrication.

After lubricating the rotor and bearings, it is injected

through orifices on a closed thread near the suction end

of the rotors. The oil is automatically injected because

of the pressure difference between the discharge pres-

sure and the reduced pressure at the suction end of the

rotors. This lubricates the rotors as well as provides an

oil seal against leakage around the rotors to assure re-

frigerant compression (volumetric efficiency).

The oil also provides cooling by transferring much of

the heat of compression from the gas to the oil keeping

discharge temperatures down and reducing the chance

for oil breakdown.

Oil injected into the rotor cage flows into the rotors at

a point about 1.2 x suction. This assures that a required

minimum differential of at least 1.8 bar exists between

discharge and 1.2 x suction, to force oil into rotor case,

a minimum of 0.6 bar is all that is required to assure

protection of the compressor. Oil pressure is measured

as the difference between discharge pressure and the

pressure of the oil entering the rotor case.

Maximum working pressure of the oil separator is 31

bar (450 psi). A relief valve is installed in the oil sepa-

rator piping. The oil level should be above the mid-

point of the “lower” oil sight glass when the compres-

sor is running. The oil level should never be above the

top of the “upper” sight glass.

Oil temperature control is provided through liquid in-

jection activated by the microprocessor, utilizing a tem-

perature sensor, and a solenoid valve.

OIL COOLER

Compressor oil cooling is provided by refrigerant liq-

uid, which is injected into the rotor suction when the

temperature setpoint has been exceeded.

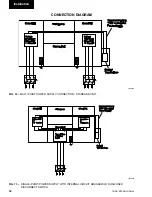

REFRIGERANT CIRCUITS

Each refrigerant circuit uses copper refrigerant pipe

formed on computer controlled bending machines to

reduce the number of brazed joints resulting in a reli-

able and leak resistant system.

Liquid line components include: a manual shut-off

valve with charging port, a high absorption removable

core filter-drier, a solenoid valve, a sight glass with

moisture indicator, and a thermostatic expansion valve.

Suction lines are covered with closed-cell insulation.

CONDENSER

The dual refrigerant circuit water-cooled condenser is

a cleanable shell and tube type with seamless external

finned 19 mm OD copper tubes rolled into tube sheets.

The design working pressures are 10 bar g on the wa-

terside and 23 bar (330 PSIG) on the refrigerant side

which is protected by pressure relief valve(s).

The condenser has removable steel water heads. The

water nozzles are provided with grooves for victualic

couplings.

COOLER

The 4 pass dual circuit shell and tube type direct ex-

pansion (DX) evaporator has chilled liquid circulating

back and forth across the tubes from one end to the

other. The design working pressures of the cooler are

10 bar (150 psi) on the waterside (shell) and 20 bar

(300 psi) on the refrigerant side (tubes) which is pro-

tected by pressure relief valve(s).

The water baffles are fabricated from galvanized steel

to resist corrosion. Removable heads are provided for

access to internally enhanced, seamless, copper tubes.

Water vent and drain connections are included. The

cooler is insulated with flexible closed-cell foam.

2

Содержание YCWS0313SC

Страница 12: ...YORK INTERNATIONAL 12 THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN PAGE FORMAT...

Страница 36: ...YORK INTERNATIONAL 36 THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN PAGE FORMAT Commissioning...

Страница 86: ...YORK INTERNATIONAL 86 TYPICAL CONTROL PANEL WIRING Maintenance...

Страница 87: ...FORM 201 24 NM2 87 YORK INTERNATIONAL TYPICAL CONTROL PANEL WIRING LD06957 8...

Страница 91: ...FORM 201 24 NM2 91 YORK INTERNATIONAL THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN PAGE FORMAT 9...

Страница 101: ...FORM 201 24 NM2 101 YORK INTERNATIONAL SECTION 10 SPARE PARTS This information will be available at a later date 10...

Страница 103: ...FORM 201 24 NM2 103 YORK INTERNATIONAL NOTES 11...