YORK INTERNATIONAL

26

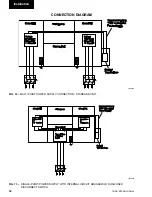

Option Flanges

One of two types of flanges may be fitted depending

on the customer or local Pressure Vessel Code require-

ments. These are Victaulic-Adapter flanges or weld

flanges. Victaulic-Adapter flanges are supplied loose

for field installation and weld flanges are factory fit-

ted. Flange dimensions are to ISO 7005 - NP10

(BS 4504 - NP10).

REFRIGERANT RELIEF VALVE PIPING

The cooler and condenser are each protected against

internal refrigerant overpressure by refrigerant relief

valves. Refer to Section 9 for details.

It is recommended that each valve should be piped to

the exterior of the building so that when the valve is

activated the release of high pressure gas and liquid

cannot be a danger or cause injury.

The size of any pipework attached to a relief valve must

be of sufficient diameter so as not to cause resistance

to the operation of the valve. Unless otherwise speci-

fied by local regulations, the internal diameter depends

on the length of pipe required and is given by the fol-

lowing formula:

D

5

= C x L

Where:

D = minimum pipe internal diameter in centimeters

L = length of pipe in meters

C = value in table below

FIG. 10 – VICTAULIC - ADAPTER FLANGES

If relief pipework is common to more than one valve

its cross sectional area must be at least the total re-

quired by each valve. Valve types should not be mixed

on a common pipe. Precautions should be taken to en-

sure that the exit of relief valves/vent pipe remain clear

of obstructions at all times.

CONDENSER COOLING LIQUID SYSTEMS

For primary cooling of units, condensers are usually

piped in conjunction with a cooling tower, although in

some cases they can be cooled by well water.

Direct Pressure Control

With liquid cooled units it is necessary to control cool-

ant flow and/or temperature into the condenser to main-

tain refrigerant pressure as constant as possible to en-

sure satisfactory operation of the expansion valves.

The aim is to maintain a stable discharge pressure as

low as possible, but at least 5.2 bar above suction pres-

sure. This can be done at a fixed value above the high-

est expected suction pressure, or by also measuring suc-

tion pressure and using differential control. In either

case condenser cooling liquid flow and temperature lim-

its must also be observed.

Inlet Temperature Control

For a cooling tower system the simplest forms of con-

trol are to use fan cycling, fan speed control, or air

damper control, with the tower having a thermostat in

its sump. This will ensure stable condenser cooling liq-

uid temperature sensing at design conditions and should

be adjusted to ensure a condenser cooling liquid enter-

ing temperature of not lower than 21°C to 24°C at lower

ambient conditions.

If these methods are not available, or a cooling tower

is not the source of cooling water, then a three way

valve recirculation system can be used with control

based on condenser inlet liquid temperature. In this case

the objective is to maintain the inlet cooling liquid tem-

perature as low as possible, although still observing

the minimum limit of 21°C to 24°C.

ELECTRICAL CONNECTION

The following connection recommendations are in-

tended to ensure safe and satisfactory operation of the

unit. Failure to follow these recommendations could

cause harm to persons, or damage to the unit, and may

invalidate the warranty.

Installation

LD06602

Содержание YCWS0313SC

Страница 12: ...YORK INTERNATIONAL 12 THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN PAGE FORMAT...

Страница 36: ...YORK INTERNATIONAL 36 THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN PAGE FORMAT Commissioning...

Страница 86: ...YORK INTERNATIONAL 86 TYPICAL CONTROL PANEL WIRING Maintenance...

Страница 87: ...FORM 201 24 NM2 87 YORK INTERNATIONAL TYPICAL CONTROL PANEL WIRING LD06957 8...

Страница 91: ...FORM 201 24 NM2 91 YORK INTERNATIONAL THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN PAGE FORMAT 9...

Страница 101: ...FORM 201 24 NM2 101 YORK INTERNATIONAL SECTION 10 SPARE PARTS This information will be available at a later date 10...

Страница 103: ...FORM 201 24 NM2 103 YORK INTERNATIONAL NOTES 11...