8 Troubleshooting

8.1.1 List of Alarms

8-2

8.1

Alarm Displays

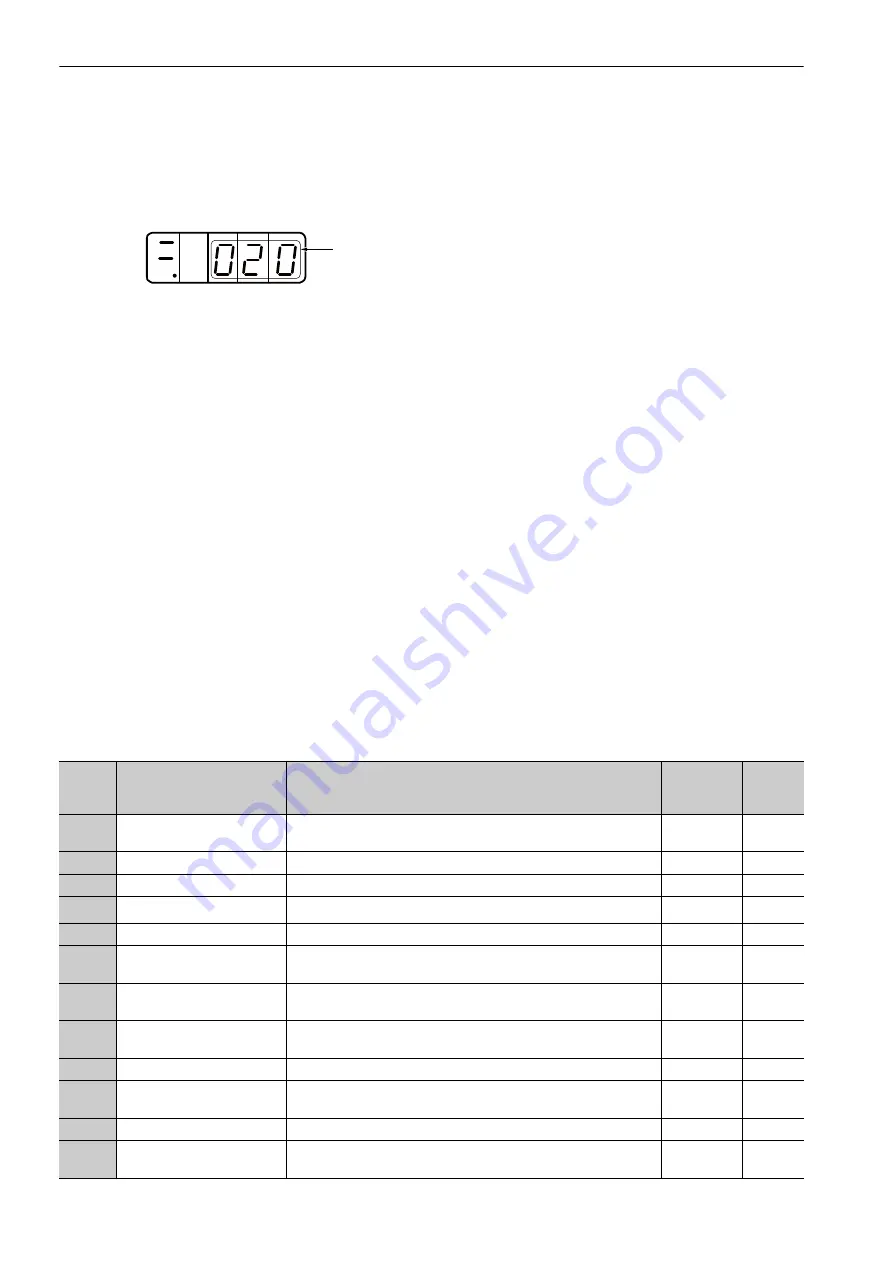

If an error occurs in the SERVOPACK, an alarm number will be displayed on the panel display. However, if

-

appears on the panel display, the display will indicate a SERVOPACK system error. Replace the

SERVOPACK.

This section provides a list of the alarms that may occur and the causes of and corrections for those alarms.

8.1.1

List of Alarms

This section provides a list of alarm names, alarm meanings, stopping methods, and alarm reset capabilities in

order of the alarm numbers.

The multi-winding drive unit manages all of the alarms and parameters. Check them in the multi-winding

drive unit.

To output specific alarms, use the ALM output in the I/O connector (CN1) on the multi-winding drive unit.

Servomotor Stopping Method

If an alarm occurs, the servomotor can be stopped by doing either of the following operations.

Gr.1: The servomotor is stopped according to the setting in Pn001.0 if an alarm occurs. Pn001.0 is factory-set

to stop the servomotor by applying the DB.

Gr.2: The servomotor is stopped according to the setting in Pn00B.1 if an alarm occurs. Pn00B.1 is factory-set

to stop the servomotor by setting the speed reference to

"

0.

"

The servomotor under torque control will

always use the Gr.1 method to stop. By setting Pn00B.1 to 1, the servomotor stops using the same

method as Gr.1. When coordinating a number of servomotors, use this stopping method to prevent

machine damage that may result due to differences in the stop method.

Alarm Reset

Available: Removing the cause of alarm and then executing the alarm reset can clear the alarm.

N/A: Executing the alarm reset cannot clear the alarm.

Example: If an A.020 alarm occurs,

“020” will flash on the display.

Alarm

Number

Alarm Name

Meaning

Servomotor

Stopping

Method

Alarm

Reset

A.020

Parameter Checksum

Error 1

The data of the internal parameter is incorrect.

Gr.1

N/A

A.021

Parameter Format Error 1

The data type of the internal parameter is incorrect.

Gr.1

N/A

A.022

System Checksum Error 1

The data of the internal parameter is incorrect.

Gr.1

N/A

A.030

*

Main Circuit Detector Error

Detection data for main circuit is incorrect.

Gr.1

Available

A.040

Parameter Setting Error 1

The parameter setting is outside the setting range.

Gr.1

N/A

A.041

Encoder Output Pulse

Setting Error

The encoder output pulse (Pn212) is outside the setting range or

does not satisfy the setting conditions.

Gr.1

N/A

A.042

Parameter Combination

Error

Combination of some parameters exceeds the setting range.

Gr.1

N/A

A.045

Multi-winding Drive Unit

Parameter Setting Error

The connected SERVOPACK is not recognized.

Gr.1

N/A

A.04A

Parameter Setting Error 2

Bank member/bank data setting is incorrect.

Gr.1

N/A

A.050

Combination Error

The SERVOPACK and the servomotor capacities do not match each

other.

Gr.1

Available

A.051

Unsupported Device Alarm

The device unsupported was connected.

Gr.1

N/A

A.0b0

Cancelled Servo ON

Command Alarm

The servo ON command (SV_ON) was sent from the host control-

ler after executing a utility function that turns ON servomotor.

Gr.1

Available

Содержание Sigma-V JUSP-MD D A Series

Страница 21: ...xxi Index Index 1 Revision History ...