55

Troubleshooting & Diagnostic:

Fridge temperature too cold in upper fridge shelf

Clean damper and air duct from ice.

Check if the damper is always in open

position.

Possible reason:

Damper is

blocked in open position.

Visual check of

damper sliding door.

Slide is broken?

If no

Change the damper

If yes

If yes

On 2007 and 2008 not Biruni appliances:

change the Main Board with a new one

introducing a complete damper sliding

door operation (opening-closing) every 25

minutes, as described in the

Service

Bulletin 4812 711 40303

. Ice formation is

avoided by the periodical operations of

the air baffle which are ‘cleaning’ the slide

path.

If no

Possible reason - On old NO IDI appliances

(before w10 2006):

Could be, when the customer change the

position of two upper shelves, that this cause a

reduction of the air circulation to the sensor. In

this case, the sensor is asking continuously for

cold air, than the food may become frozen.

To solve this problem,

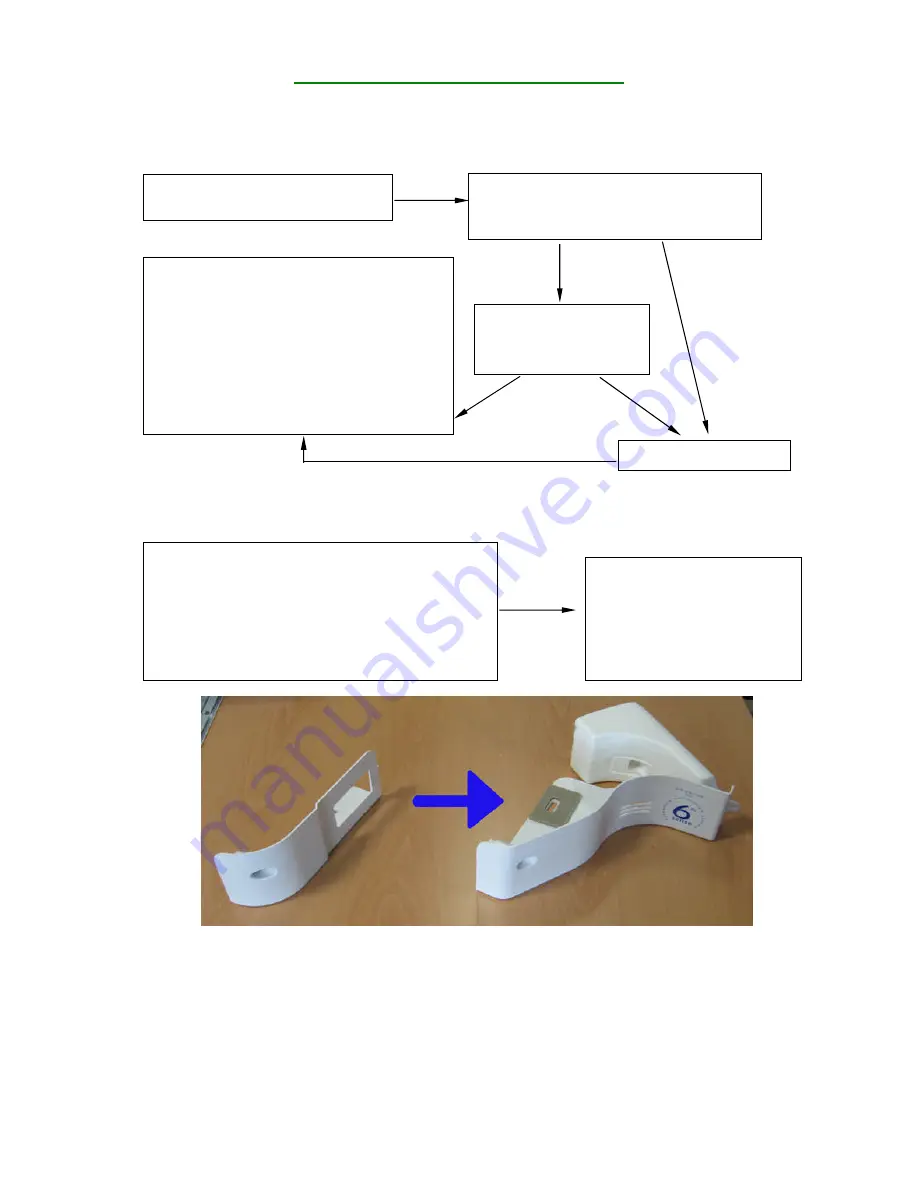

change the air baffle cover

and the sensor support in

the fridge compartment as

described in the

Service

Bulletin 4812 711 40158/2.

Содержание Cassinetta

Страница 8: ...8 ...

Страница 41: ...41 Inside Ice Sensor Guide Ice Full Test Switch Not Used SbS NO IDI Sankyo ice maker ...

Страница 43: ...43 TEMPERATURE VS RESISTANCE VALUE TABLE FOR SANKYO ICEMAKER ...

Страница 44: ...44 ...