4. Connect the other end of the tubing (the tubing connected to the inlet of the flow cell) to the

outlet of the flow cell.

5. The fluidics path of the flow cell is now completely isolated from the rest of the LC system.

6. Record a run (without injection of sample) to measure/evaluate the background cell current

(Icell) and noise.

7. Compare the obtained values of the cell current and noise with the values observed before

the stop flow with the pump on.

Results:

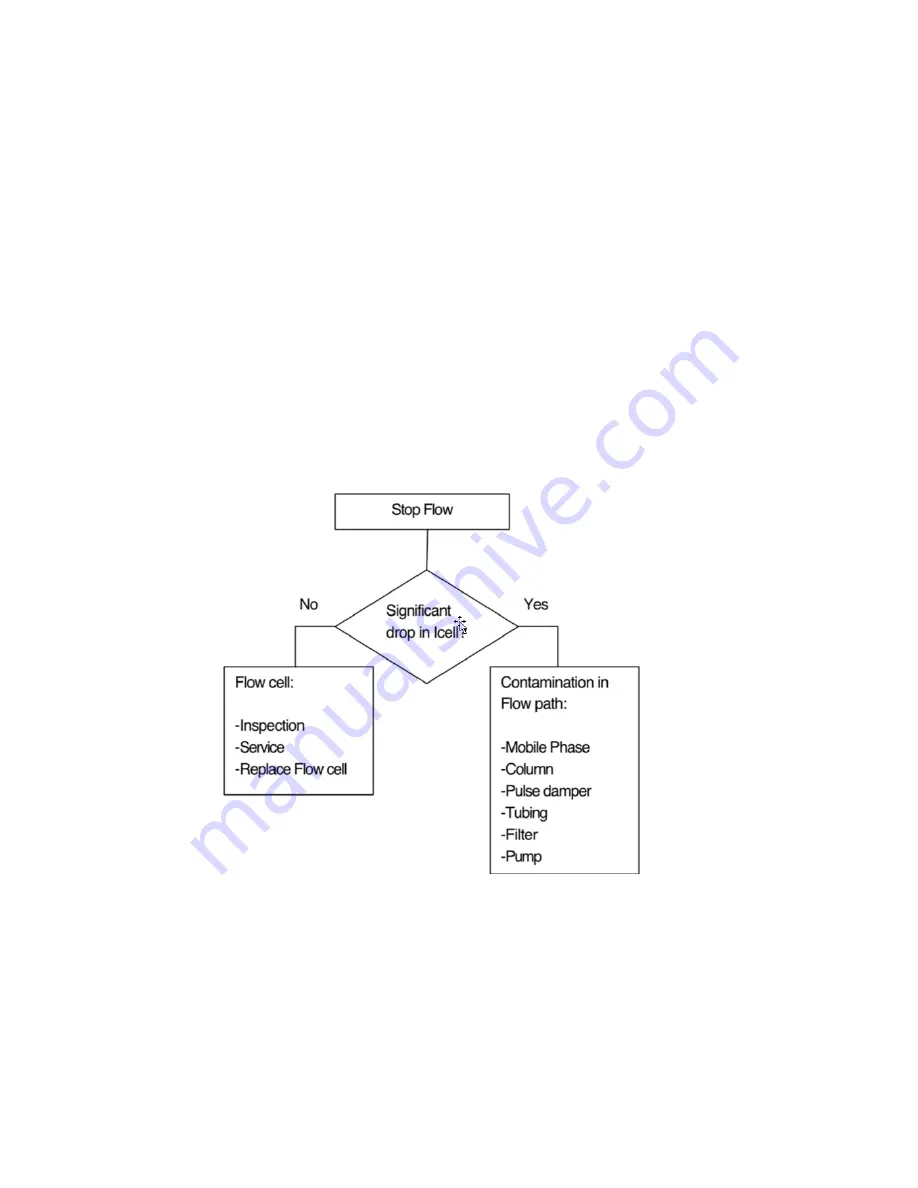

Icell: If a significant drop in Icell is observed (for example, a drop of more than 50%), it is

an indication that the problem is not flow cell related but originates from other parts of the

LC system. The most obvious reasons for a high background current are electrochemically

active contaminants in the mobile phase, column bleeding, and leaking pulse damper.

These causes can be systematically eliminated by replacing the mobile phase or

disconnecting the column or pulse damper, and so on, and then re-evaluating the cell

current.

Figure 12–6: Icell-Stop Flow

Noise: If only a significant drop in noise is observed, it could signal, for example, a pump

problem (check valves, air in pump head, compressibility issues, or leaking seals).

December 16, 2021, 715007395 Ver. 00

Page 96