VMAC

– Vehicle Mounted Air Compressors

VMAC Technical Support:

1-888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

32

Setup, Performance Testing and

Adjustments

This system has been adjusted at the factory for general operation.

System operation can be tested using the tools that will be operated by the

system or by using the VMAC Test Tool (A700052) with the 30 cfm (1/8 in)

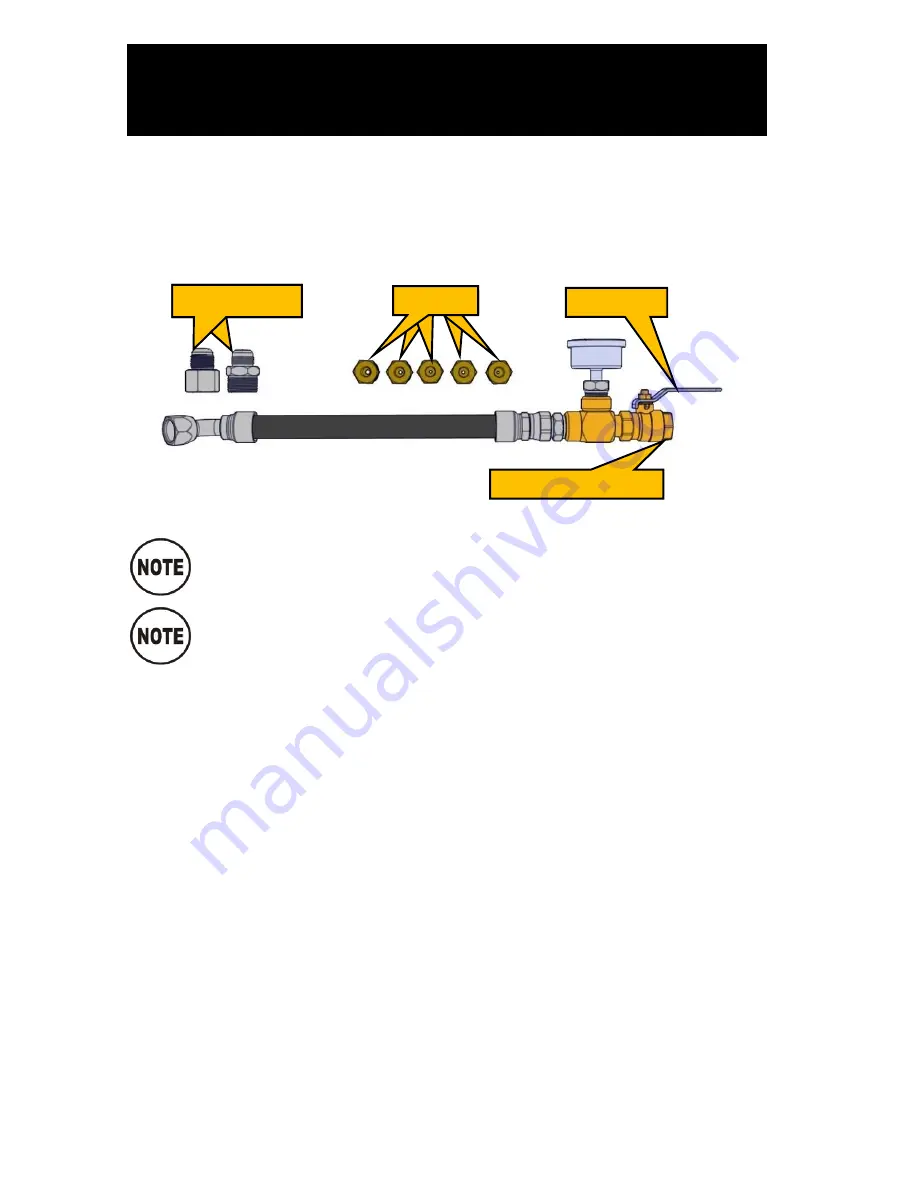

orifice in the outlet to simulate tool use (Figure 24).

Figure 24

– A700052 Test Tool

Ensure there are no leaks in the test tool. The system may not

idle down or unload if there are leaks in the lines or fittings.

Disconnect all downstream equipment (hose reels, etc.) and

remove the ball valve from the compressor discharge. Connect

the test tool directly to the discharge fitting on the WHASP

Tank.

Install the VMAC test tool at the system outlet with the 30 cfm (1/8 in)

orifice.

Ensure that the ball valve on the test tool is closed.

Start the compressor system and allow the engine to run until it is at

operating temperature.

Ensure the tension on the unloader valve is released to allow the

compressor to build to full pressure.

Observe the pressure gauge, it should indicate approximately 150 psi

(factory setting).

Slowly open the ball valve on the test tool and observe the operation. The

engine speed should increase when the pressure drops to 130 psi (20 psi

below system pressure).

With the ball valve fully open, the pressure should stabilize at

approximately 100 psi (this simulates a tool operating at 30 cfm).

Close the ball valve to allow the system pressure to rise.

Once testing is complete, follow the normal shut off procedure.

JIC adaptors

Orifice

Ball valve

Install orifice here

Содержание G300003

Страница 1: ...Gas Engine Driven 30 CFM Air Compressor Installation Owner s and Service Manual G300003...

Страница 2: ......

Страница 97: ...This page intentionally left blank...

Страница 98: ...This page intentionally left blank...

Страница 99: ......

Страница 100: ......